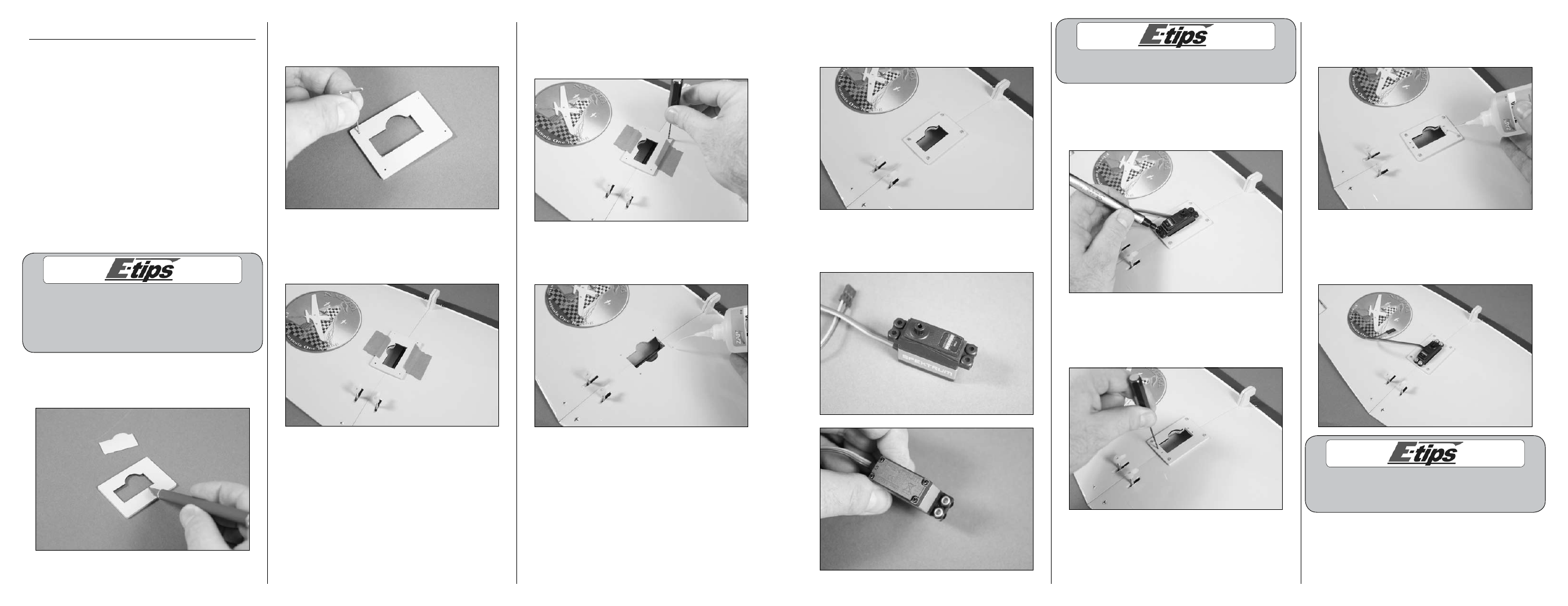

Installing the aileron servo – E-flite LR-1A Pogo ARF 15e User Manual

Page 5

8

E-flite LR-1A Pogo 15e ARF Assembly Manual

9

E-flite LR-1A Pogo 15e ARF Assembly Manual

6. Use a #1 Phillips screwdriver to install the four

2mm x 12mm sheet metal screws to secure the

mount to the wing.

7. Follow the instructions provided with the servo to

install the rubber grommets and brass eyelets in the

servo mounting tabs.

Install the rubber grommets and eyelets in the

rudder and elevator servos at this time as well.

8. Place the aileron servo in the mount with the

output of the servo facing the leading edge of the

wing. Use a felt-tipped pen to transfer the locations

for the servo mounting screws onto the mount.

9. Use a pin vise and 1/16-inch (1.5mm) drill bit

to drill the holes through the mount and into the

wing. Use care not to drill holes through the bottom

of the wing.

10. Place 2–3 drops of thin CA in each hole to

harden the surrounding wood. This harder surface

makes the screws more secure when installed.

11. Place the servo back into the mount. Use a

#1 Phillips screwdriver to install the four screws

included with the servo to secure the aileron servo

in position.

When using a computer radio, it is recommended

to start with a new model that has been reset

to remove any sub-trims or programming.

Installing the Aileron Servo

Required Parts

Wing assembly

Aileron servo mount

Metal clevis (2)

Aileron servo with hardware

Transmitter

Receiver

2mm nut (2)

Battery

Silicone keepers (2) Nylon pushrod keeper (2)

2mm x 12mm sheet metal screw (4)

Aileron linkage wire, 4

3

/

4

-inch (120mm) (2)

Required tools and Adhesives

Low-tack tape

Hobby knife with #11 blade

Pin vise

Ruler

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Thin CA

Felt-tipped pen

Needle nose pliers Flat blade screwdriver

Side cutter

Phillips screwdriver: #1

When cutting the covering make sure not to cut into

the underlying wood and weaken the underlying

structure. Another option is to use a soldering

iron or hot knife to melt the covering, rather than

cutting, to avoid damaging the stabilizer.

1. Use a hobby knife with a #11 blade to remove

the covering from the inside of the aileron servo

mount as shown.

2. Use a T-pin to poke holes through the covering

in the locations for the mounting screws at each

corner of the mount.

3. Position the aileron servo mount on the wing.

Align the opening in the mount with the opening in

the wing. Use low-tack tape to hold the mount to

the wing.

4. Use a pin vise and 1/16-inch (1.5mm) drill bit

to drill the holes through the mount and into the

wing. Use care not to drill holes through the bottom

of the wing.

5. Place 2–3 drops of thin CA in each hole to

harden the surrounding wood. This harder surface

makes the screws more secure when installed.