Propeller and spinner installation, Wing and stabilizer installation – E-flite LR-1A Pogo ARF 15e User Manual

Page 11

20

E-flite LR-1A Pogo 15e ARF Assembly Manual

21

E-flite LR-1A Pogo 15e ARF Assembly Manual

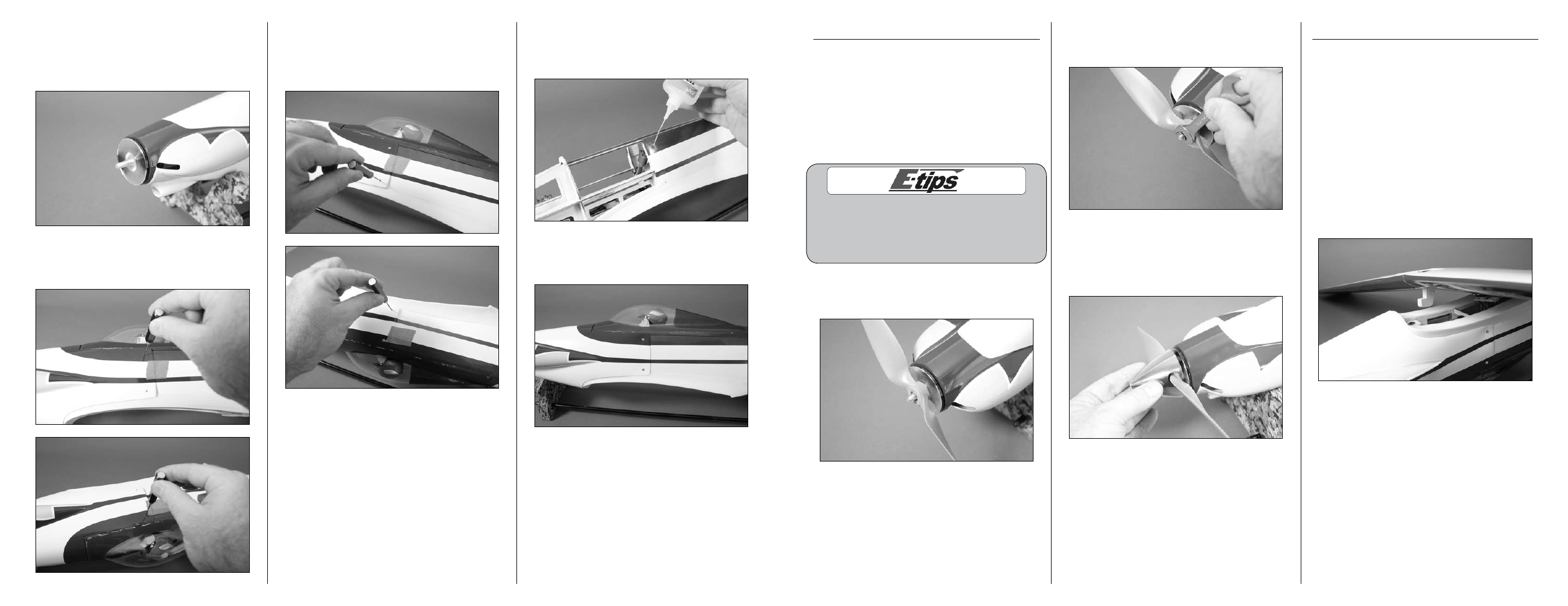

Propeller and Spinner Installation

Required Parts

Fuselage assembly

Propeller nut

Propeller washer

Propeller

Spinner cone with screw

Spinner backplate with adapter

Required tools and Adhesives

Hex wrench or ball driver: 3/32-inch

Open end or box wrench: 10mm

Always balance your propeller. An unbalanced

propeller can cause vibrations to be transmitted

into the airframe, which could damage the

airframe or other components as well as

produce unwanted flight characteristics.

1. Slide the spinner backplate and adapter on

the motor shaft. Then position the propeller on the

adapter as shown.

2. Install the propeller washer and nut on the

adapter. Use a 10mm box wrench or open end

wrench to tighten the propeller nut.

3. Position the spinner cone. Make sure the

opening in the spinner cone does not contact the

propeller. Use a 3/32-inch hex wrench or ball

driver to tighten the screw that secures the spinner

cone.

Wing and Stabilizer Installation

Required Parts

Wing assembly

Fuselage assembly

Wing bolt plate

4mm washer (2)

4mm x 30mm machine screw (2)

Required tools and Adhesives

30-minute epoxy

Phillips screwdriver: #2

Epoxy brush

Ruler

Felt-tipped pen

Mixing cups

Mixing sticks

Paper towels

T-pin

Low-tack tape

Rubbing alcohol

Hobby knife with #11 blade

1. Attach the wing to the fuselage by sliding the

tab on the wing under the plate inside the fuselage.

5. Check that the cowl is aligned with the spinner

backplate. There should also be a 5/64-inch

(2mm) gap between the backplate and cowl.

You may need to remove the tape and adjust the

position of the cowl for proper alignment.

6. Once aligned, use a pin vise and 1/16-inch

(1.5mm) drill bit to drill through the top two holes

in the cowl and into the fuselage.

7. Install two 2mm x 6mm sheet metal screws using

a #1 Phillips screwdriver to hold the position of the

cowl. Use a pin vise and 1/16-inch (1.5mm) drill

bit to drill the remaining two holes for mounting the

cowl.

8. Remove the cowl from the fuselage. Place

2–3 drops of thin CA in each hole to harden the

surrounding wood. This harder surface makes the

screws more secure when installed.

9. The cowl can now be secured to the fuselage

using the four 2mm x 6mm sheet metal screws.

Tighten the screws using a #1 Phillips screwdriver.