Electrical installation – Banner SI-HG63 Hinge Style Switches User Manual

Page 3

CAUTION:

End Stops.

Do not use the switch as an end stop. The operating angle of the switch must be limited by outer end

stops.

Setting the Switch Point

CAUTION:

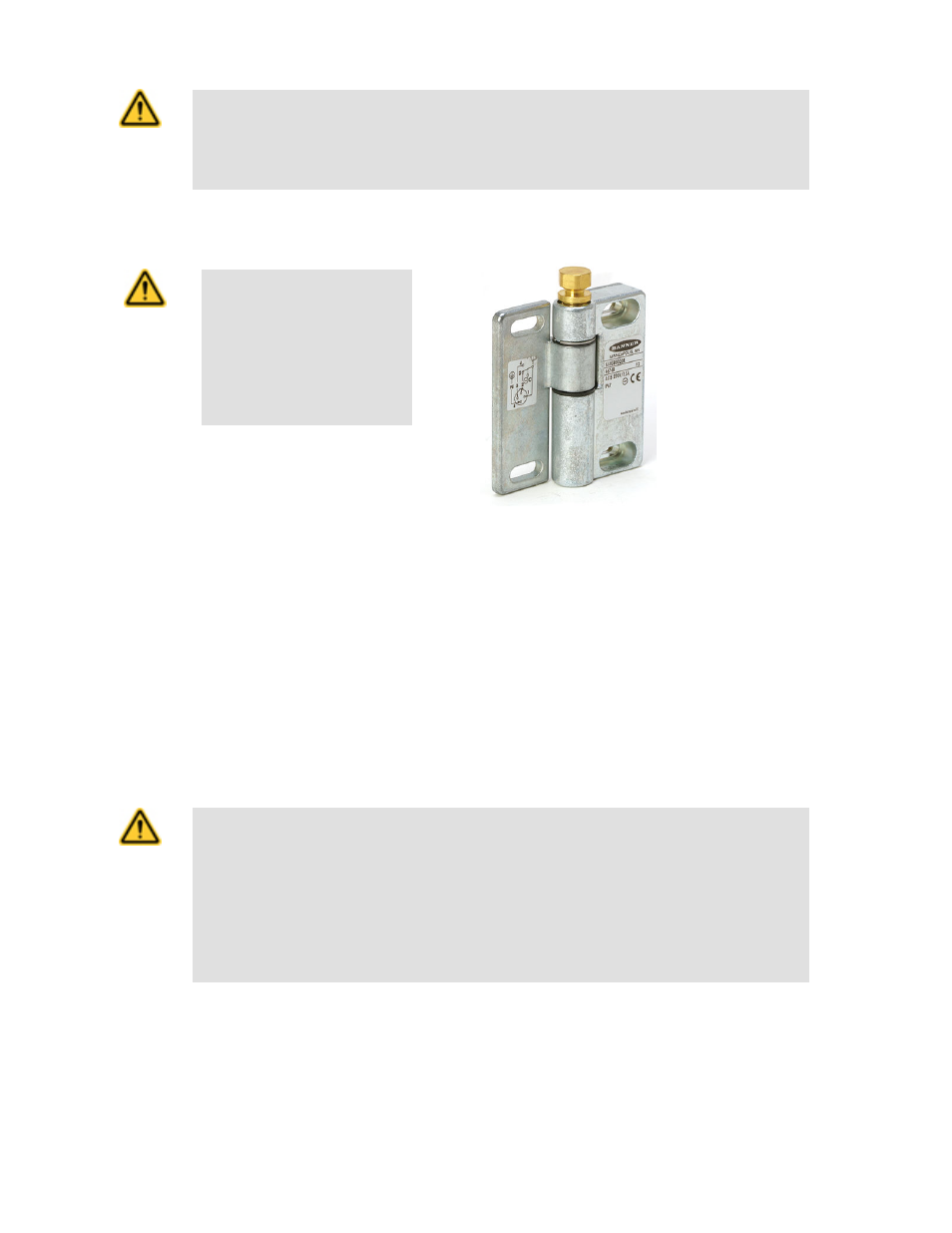

Remove Set Screw Head.

Shear off the hexagonal head of

the set screw after it is set, and

before using the switch. If not, the

safe activation of the switch can

not be ensured.

Figure 1. Hinge switch with set screw head in place

1. Ensure the hinge switches (and blind hinges, if used) are properly mounted and the guard or gate swings freely throughout its range

of motion without binding. If binding is noticed, repeat the mechanical installation procedures.

2. Place the guard in its closed and latched position.

After the switch point is set, it cannot be changed. Before proceeding, verify the installation is correct and the resulting switching

action is what is expected.

3. Tighten the hexagonal set screw head with a 13 mm open-ended wrench (rotate clockwise when switch is mounted vertically and the

nut is on top). See

Figure 1. Hinge switch with set screw head in place

on page 3.

4. Continue tightening until the set screw head shears completely off the switch. When the screw head shears off, the switch point is

set.

Electrical Installation

CAUTION: Electrical Installation

Two safety switches must be used for each interlock guard to achieve control reliability or Safety

Category 4 (per ISO 13849-1, EN 954-1) of a machine stop circuit. Use of only one safety switch per

interlock guard is not recommended.

In addition, normally-closed safety contacts from each of the two safety switches should be connected to

the two separate inputs of a 2-channel safety module or safety interface. This is required to provide moni-

toring for safety switch contact failure, and to provide the necessary reset routine, as required by IEC

60204-1 and NFPA 79 machine safety standards.

Hinge Wing Safety Interlock Switches

P/N 046735 Rev. C

www.bannerengineering.com - tel: 763-544-3164

3