3 installation, 1 setting up the instrument, 1 packaging – Metrohm 930 Compact IC Flex Oven/SeS/PP/Deg User Manual

Page 23: 2 checks, 3 location, 2 capillary connections in the ic system, Setting up the instrument, Packaging, Checks, Location

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

930 Compact IC Flex Oven/SeS/PP/Deg (2.930.2560)

■■■■■■■■

13

3 Installation

3.1

Setting up the instrument

3.1.1

Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2

Checks

Immediately after receipt, check whether the shipment has arrived com-

plete and without damage by comparing it with the delivery note.

3.1.3

Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctu-

ations and direct sunlight.

3.2

Capillary connections in the IC system

Generally speaking, capillary connections between two components of an

IC system are made up of one connection capillary and two pressure

screws used to connect the capillary to the respective components.

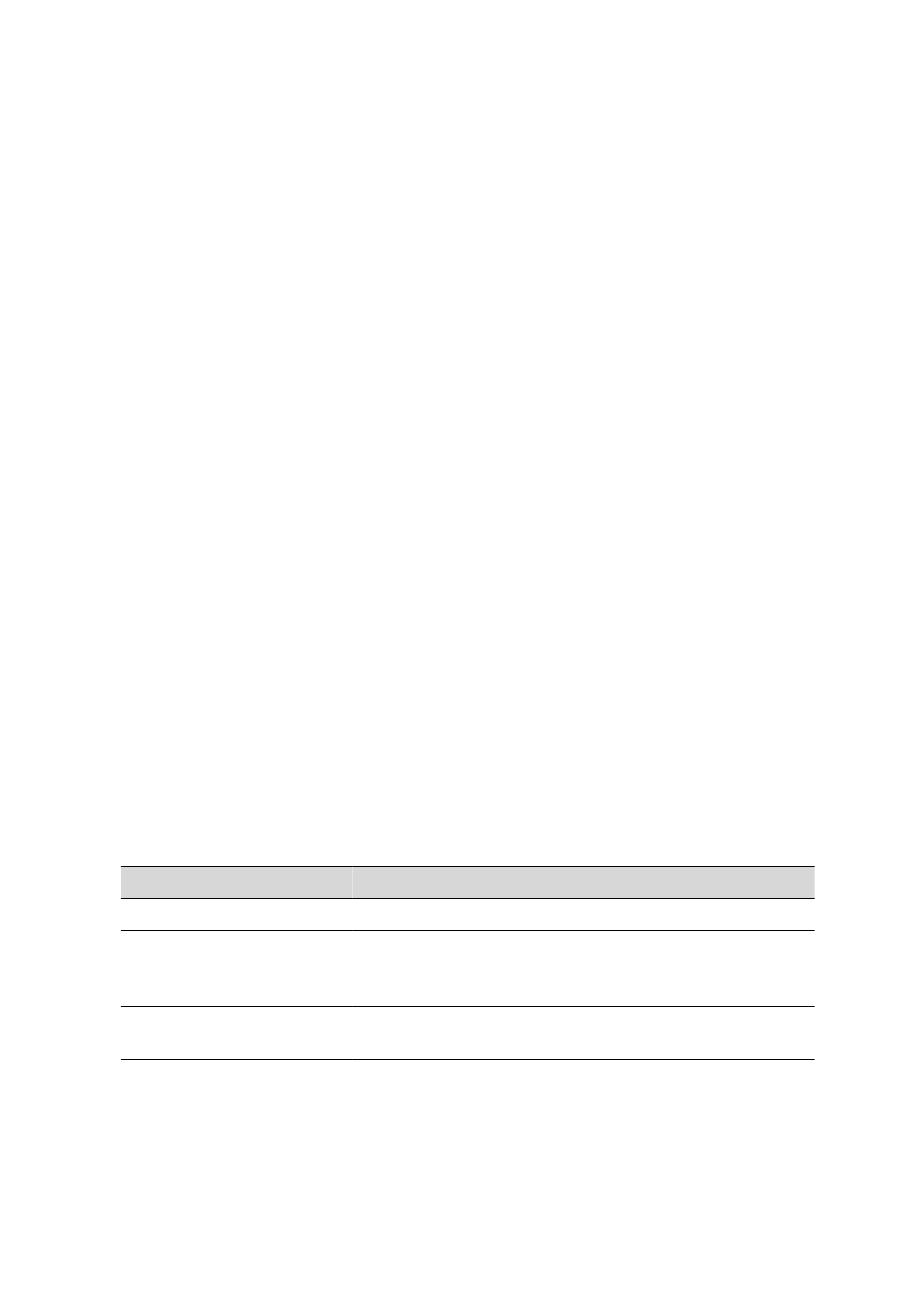

Pressure screws

Three types of pressure screws are used in the IC system:

Number

Designation

Use

6.2744.010 / 6.2744.014

Pressure screw

On the injection valve

6.2744.070

Pressure screw, short

High-pressure pump, purge

valve, inline filter, pulsation

absorber, separation columns

6.2744.090

Pressure screw, long

MCS, sample degasser, 12-

port valve

Pressure screws are tightened and loosened by hand. A tool is not

needed.