Rockwell Automation FD86N Drive Systems Enclosure Hardware User Manual

Page 17

Installing the FD86N Enclosure

2-3

Publication S-3062 – November 1997

Lifting the Enclosure

For lifting instructions, see the Dimension Sheet for your enclosure and

Figures 2.1, 2.2, and 2.3.

When lifting the enclosure:

•

Use slings for pickup points.

•

Use slings with load-rated safety hooks or shackles.

•

Use the proper slings to ensure that the load is equalized at all lift points.

•

Use spreader bars (see Figure 2.3) and padding to prevent damage to

the enclosure and enclosed equipment.

•

Do not pass ropes or cables through the lifting angle support holes.

•

Use rigging lengths that compensate for any unequal weight distribution

of the load and that support the enclosure in an upright position.

•

The angle between the rigging and enclosure must be at least 45°. This

reduces tension on the slings and compression on the lifting angles.

•

Keep enclosure upright.

•

Do not jolt the enclosure.

!

ATTENTION: When detaching skids, be aware that

the enclosure can be top-heavy. Exercise caution.

ATTENTION: When the enclosure is removed from

the skids, brace and block the enclosure until it is

permanently secured.

!

ATTENTION: Lift the sling so that the load is

equalized at the pickup points. Use spreader bars as

required. Minimum sling angle is 45°.

ATTENTION: Tilting the FD86N enclosure can

damage the enclosure, especially if it encloses heavy

equipment.

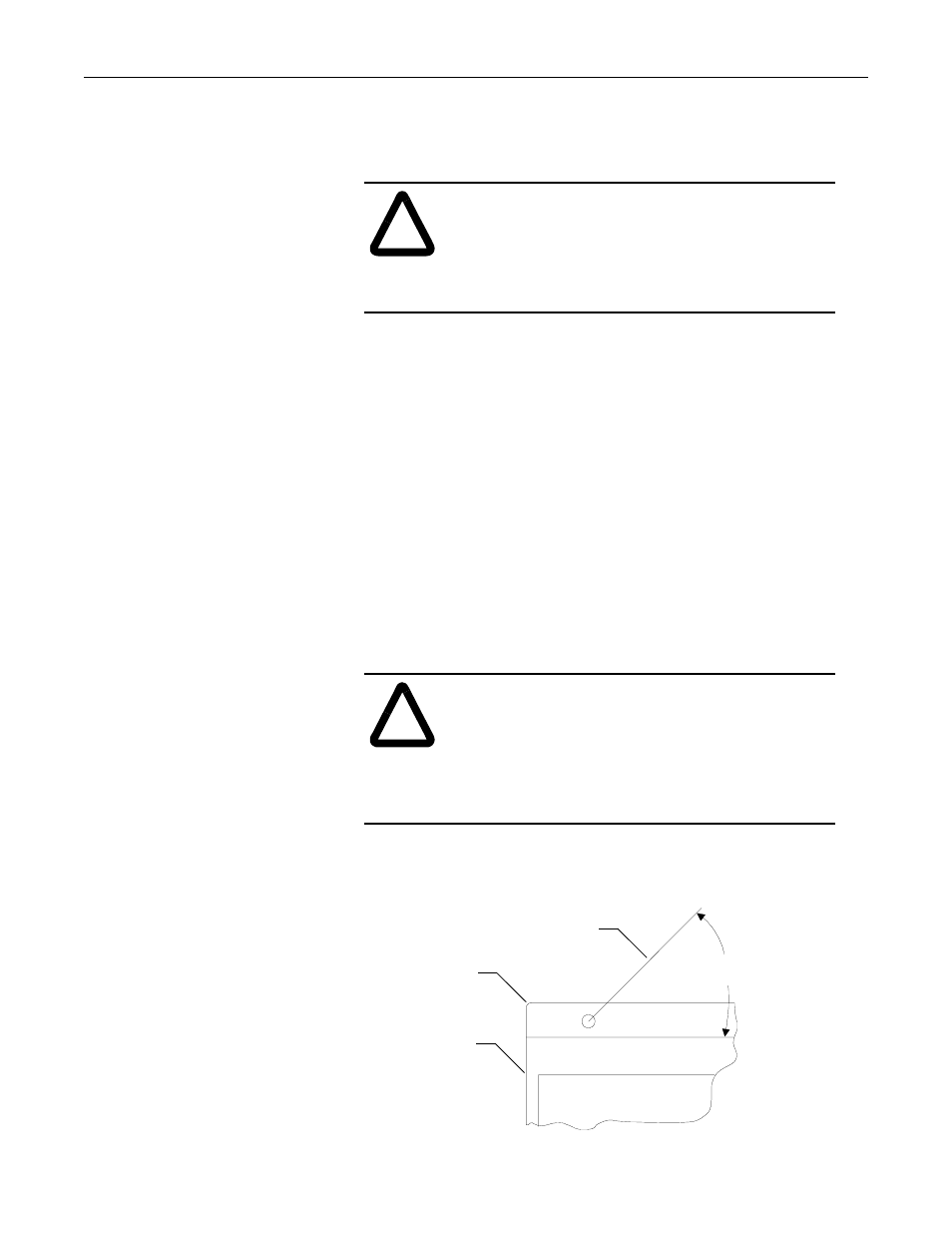

Figure 2.1

Minimum Sling Angle Requirement

45° Minimum

Sling

Lifting Angle

Enclosure