Pre-charge connections on, Pre-charge connections on drives with dc input – Rockwell Automation 20D PowerFlex 700H/S Frame 14 Replacement Power Structures User Manual

Page 21

PowerFlex® 700S and 700H Frame 14 Replacement Power Structures

21

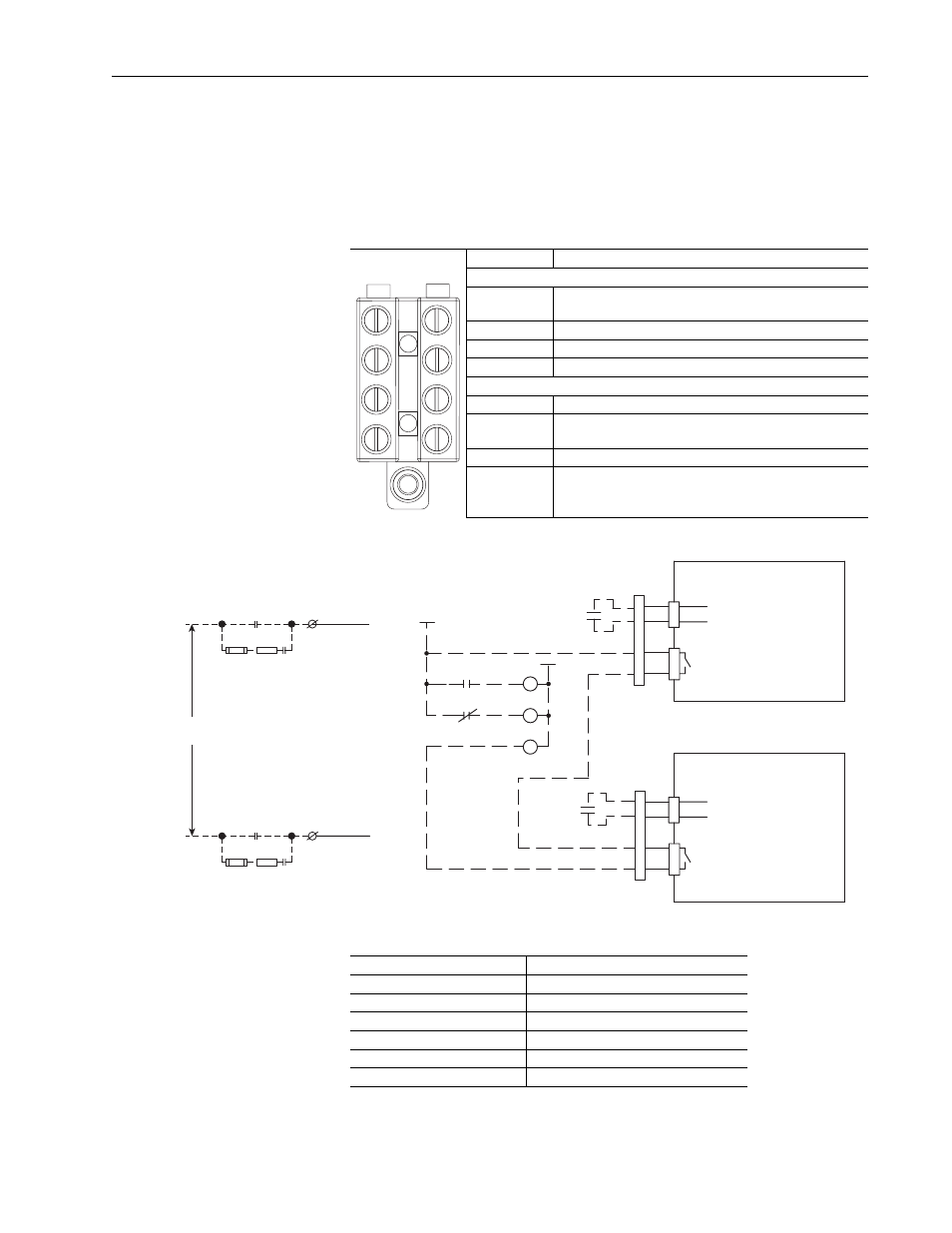

Pre-Charge Connections on Drives with DC Input

You must connect the ASIC board connectors X9 and X15 to the X50

terminal block for the pre-charge circuit. Refer to publication

PFLEX-IN006

…

, Installation Instructions - PowerFlex 700S and 700H

Frame 9-14 Drives, for more information regarding the pre-charge circuit.

X50 Terminal Block Connections

Figure 8 Sample Pre-charge Wiring Diagram

ASIC Board Charge Relay Contact Ratings

X50 Terminal Block Terminal

Description

Power Module 1

3

Charge Relay Contact (Jumper to Power Module 2 Terminal

4)

4

Charge Relay Contact

1

Precharge Complete Signal (+24V DC)

2

Precharge Complete Signal (Common)

Power Module 2

3

Charge Relay Contact

4

Charge Relay Contact (Jumper to Power Module 1 Terminal

21)

1

Precharge Complete Signal (+24V DC)

2

Precharge Complete Signal (Common)

1

2

3

4

M

F2

R2 CR2

DC+

DC Source

DC-

CR2

R1

F1

M

ASIC

Board

#1

X9

X15

25

26

21

22

23

23

22

X15

26

21

25

Precharge

Complete*

X9

CR1

M

CR1

CR2

M

M

1

2

3

4

PU2

X50

PU1

X50

1

2

3

4

ASIC

Board

#2

Precharge

Complete*

M

*Refer to the “ASIC Board

Charge Relay Contact

Ratings” table below.

External precharge circuitry

is shown as dashed lines.

Load

Resistance load (cos

φ

= 1)

Rated load

8 A at 250 VAC: 5 A at 30 VDC

Rated carry current

8 A

Max. switching voltage

250 VAC; 30 VDC, (400 VAC)

Max. switching current

AC 8 A; DC 5 A

Max. switching power

2,000 VA; 150 W

Failure rate (reference value)

5 VDC 10 mA (for gold plating 0.35 µ min.)