Rockwell Automation TLY-Series Servo Motor User Manual

Page 16

16

TL-Series Servo Motors

Publication TL-IN003A-EN-P — June 2007

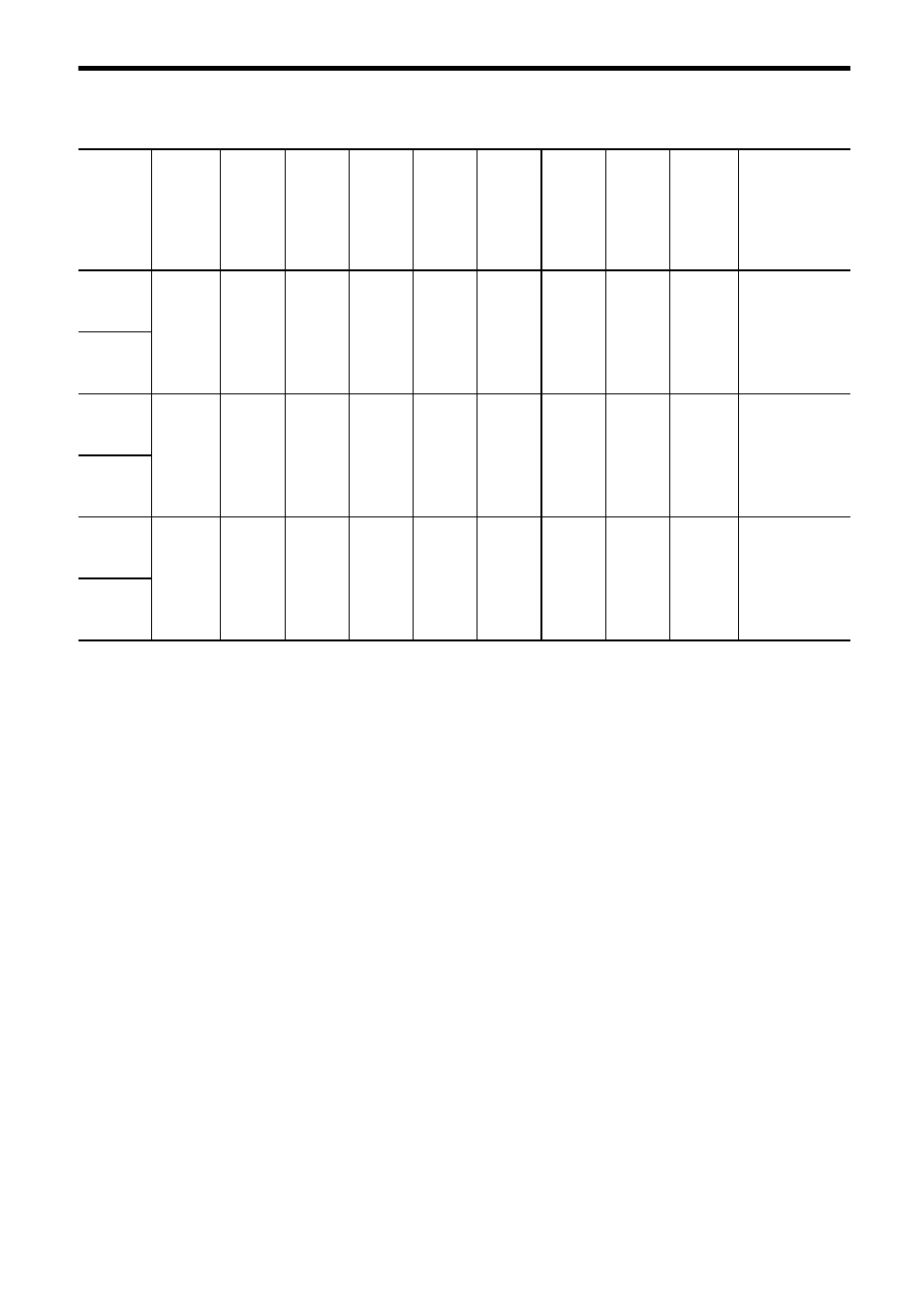

NEMA Mount Dimensions, Approx. (cont.)

4

Tolerance for this dimension is: TLY

-A1xx -0.021 mm (-0.0008 in.); TLY-A2xx -0.025 mm (-0.001 in.); TLY-A25xx -0.03 mm (-0.0012 in.).

5

TLY

-A1xx has two threaded holes, TLY-A2xx and TLY-A25xx have four mounting holes.

Mounting holes are S diameter on M diameter bolt circle.

6

Tolerance for cable length is ±50.0 mm (±1.97 in.). Minimum bend radius is 15.00 mm (0.59 in.).

7

Tolerance for this dimension is: -0.38 mm (-0.015 in.).

8

Tolerance for this dimension is: +0.051 mm (+0.002 in.).

9

X-Y tolerance for this dimension is: TLY -0.051 mm (-0.002 in.). Length is untoleranced.

Motor

Series

TLY-A

N

4

mm

(in.)

NB

mm

(in.)

P

mm

(in.)

S

5

mm

(in.)

T

mm

(in.)

TB

mm

(in.)

CAB

6

mm

(in.)

G

7

mm

(in.)

F

8

mm

(in.)

Key

9

mm

(in.)

120

22.0

(0.8661)

—

42.0

(1.65)

8-32

Thread

2.0

(0.08)

—

1000

(39.4)

— —

—

130

220

38.1

(1.50)

—

56.4

(2.22)

5.5

(0.217)

1.5

(0.06)

—

1000

(39.4)

10.92

(0.43)

3.175

(0.125)

(0.125 x 0.125

x 0.9375)

230

2530

73.02

(2.875)

—

86.0

(3.39)

5.5

(0.217)

1.6

(0.06)

—

1000

(39.4)

13.13

(0.517)

4.763

(0.1875)

(0.187 x 0.187

x 1.156)

2540

NEMA motor flanges and shafts are designed to inch dimensions. Other frame areas are designed to metric

dimensions. Conversions are mathematically calculated.