Hapter, Diagnostics and troubleshooting, 1 drive faults and corrective actions – Rockwell Automation TD200 AC Drive V1.0, 0.3-20V RMS, 3-Ph, 63A User Manual

Page 27

Diagnostics and Troubleshooting

7-1

C

HAPTER

7

Diagnostics and Troubleshooting

7.1

Drive Faults and Corrective Actions

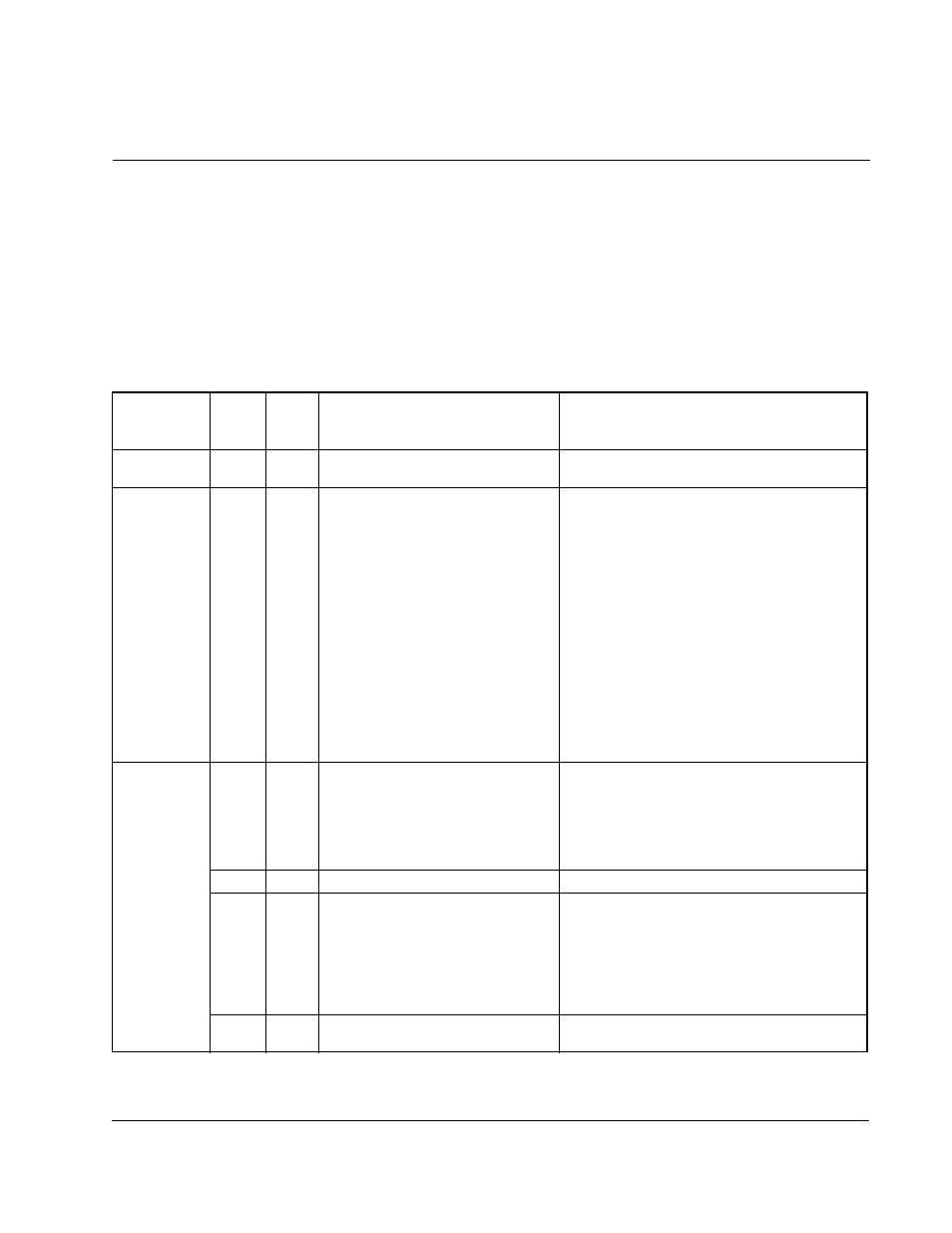

The drive has two status LEDs that can be used to diagnose drive faults. Table 7.1

lists some possible drive faults and their corrective actions.

To reset a fault, toggle the ON/OFF switch to OFF. When the switch is returned to the

ON position, the drive will attempt to restart.

Table 7.1 – Drive Status Indicators

Status

Motor

LED

(M)

Drive

LED

(D)

Possible Cause

Corrective Action

Drive is

running

ON

ON

Drive is running (normal status).

Drive runs,

but not at

commanded

speed

ON

ON

Internal speed reference set

improperly

External peed reference not present

HI/LO input has voltage applied

Current limit set too low

V/Hz jumpers set improperly

Excessive load

Input voltage too low (< 25 VDC,

nominal)

Power source not delivering enough

current

Check jumper settings (J1 - J8).

Check speed reference jumpers (J1, J17 - J19),

POT1 and POT2.

Remove input voltage.

Increase J13 - J16 settings.

Set J9 - J12 to proper motor setting.

Reduce load.

Increase input voltage.

Supply appropriate input current.

Drive is

stopped

ON

ON

Overtemperature - result of

inadequate air flow, excessive

ambient temperature, and/or

excessive load current

Overvoltage - voltage exceeds 32

VDC

Let drive cool down, then cycle ON/OFF input.

Unit will automatically restart when voltage

returns to normal input levels.

ON

OFF

Internal Drive Fault

Cycle power. If fault repeats, replace drive.

OFF

ON

Overcurrent - sustained overload

exceeding limits in table 2.3.

Instantaneous Overcurrent (IOC) -

short circuit or other fault applied to

the output

Ground Fault

Reduce current load.

Check output circuitry; reduce current load.

Check motor and motor wiring.

OFF

OFF

Input power is too low or ON/OFF

input is low (OFF).