1 wiring the external control inputs and outputs, 2 wiring the output power to the motor – Rockwell Automation TD200 AC Drive V1.0, 0.3-20V RMS, 3-Ph, 63A User Manual

Page 20

4-2

TD200 AC Drive Installation and Operation

4.1

Wiring the External Control Inputs and Outputs

Table 4.1 describes the external control circuits shown in figure 4.1. All control circuits

should be wired as follows:

•

use 12 to 18 AWG wire terminated with ring lugs sized for a #8 stud.

•

torque all connections between 11 to 13 in-lb.

4.2

Wiring the Output Power to the Motor

Table 4.2 describes the drive output power connections shown in figure 4.1. All output

power connections should be wired as follows:

•

Minimum 6 AWG wire terminated with ring lugs sized for a 3/8” stud (drive end).

•

torque all connections between 90 to 100 in-lb.

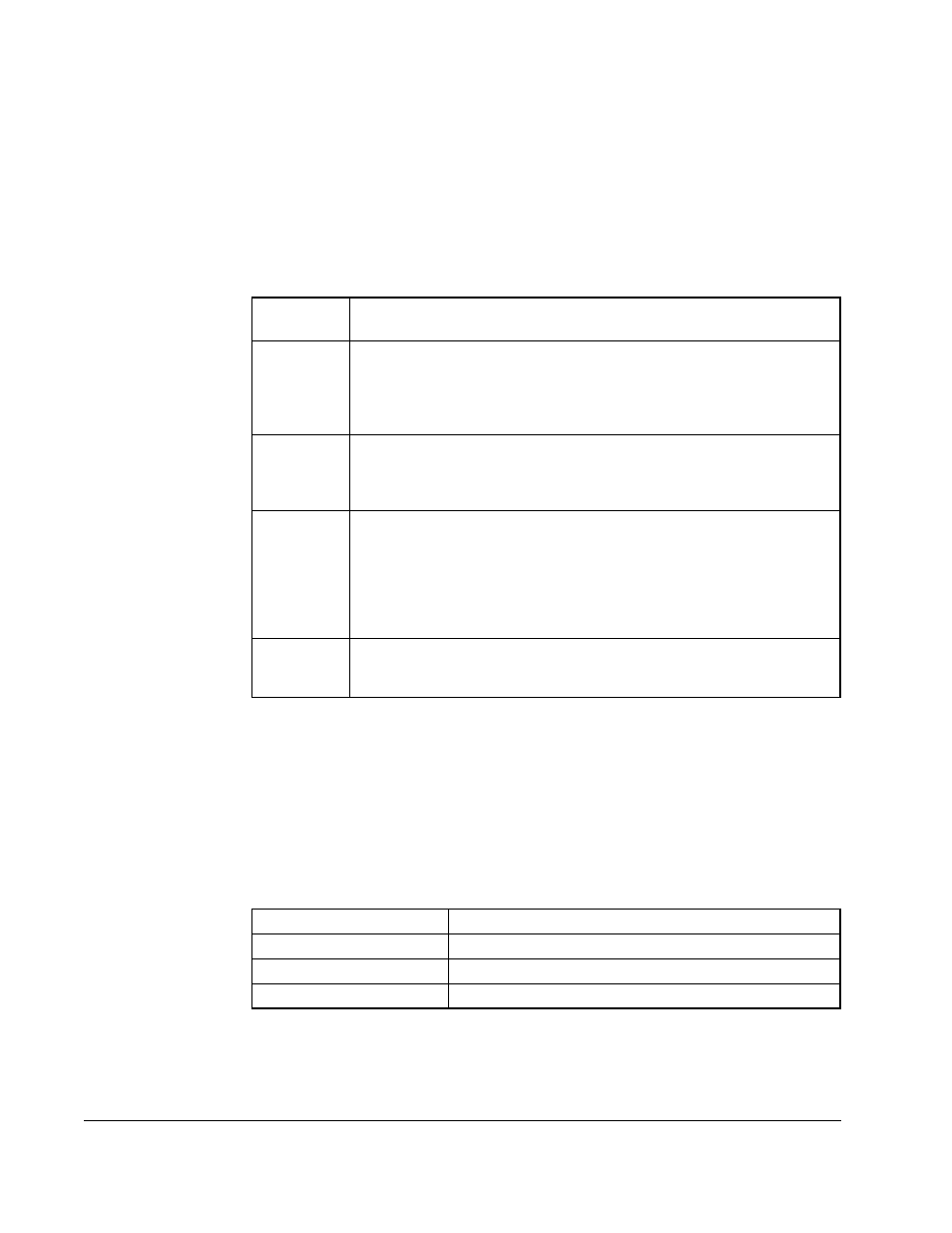

Table 4.1 – External Control Inputs and Ouputs

Terminal

Label

Function

ON/OFF

ON = Closed to run motor

OFF = Open to stop motor

There is an approximate delay of 1.0 second at startup.

Peak input current = 0.2 A, approximate 0.02 A average continuous

HI/LO

LO (speed) = Closed for 3/4 of maximum speed.

HI (speed) = Open for maximum speed.

Nominal input current = 50 mA

POT1

POT2

Analog speed reference input. POT1 is the signal and POT2 is the

return.

The input signal range is 0 to 4.5 VDC.

May also be used with a 1000 ohm pot between POT1 and POT2 if

appropriate jumpers are selected.

FAULT

Output fault indication. The fault output will sink up to 500 mA when

operating normally, and sink 0 A when the drive is faulted or not

activated.

Table 4.2 – Output Power Connections

Terminal Label

Function

U

Connect to motor terminal “U”

V

Connect to motor terminal “V”

W

Connect to motor terminal “W”