Rockwell Automation TLAR Electric Cylinders Replacement User Manual

Page 15

MP-Series and TL-Series Electric Cylinders Replacement Parts 15

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

9.

Hold the pulleys with a wrench and tighten the collar by turning the hex key

counter-clockwise to the torque shown in this table.

10.

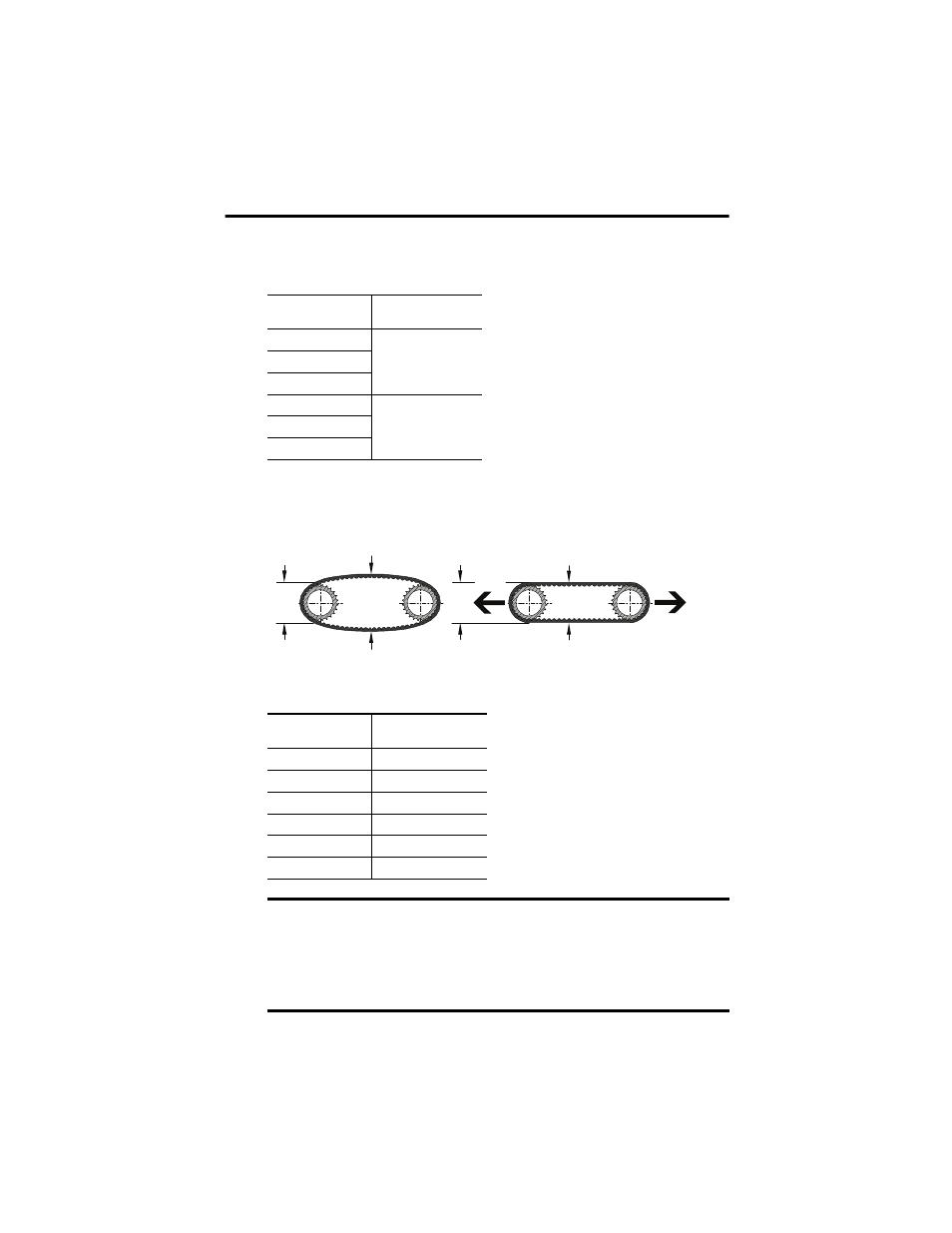

Apply pressure to the base of the motor to tension the belt.

Observe the distance a X and Y and determine this transition precisely.

This table shows the recommend belt tension values.

Cat. No.

Torque

N•m (lb•ft)

MPAR-x1xxxB-xxB/D/E

16.95 (13)

MPAR-x1xxxE-xxB/D/E

MPAR-x2xxxC-xxB/D/E

MPAR-x2xxxF-xxB/D/E

67.79 (50)

MPAR-x3xxxE-xxB/D/E

MPAR-x3xxxH-xxB/D/E

Cat. No.

Recommend Belt Tension

N (lb)

MPAR-x1xxxB-xxB/D/E

30 (6.75)

MPAR-x1xxxE-xxB/D/E

61 (13.73)

MPAR-x2xxxC-xxB/D/E

67 (15.10)

MPAR-x2xxxF-xxB/D/E

90 (20.23)

MPAR-x3xxxE-xxB/D/E

162 (36.4)

MPAR-x3xxxH-xxB/D/E

224 (50.4)

IMPORTANT

A low pretension force is better than a high pretension force.

Excessive pretension on the belt results in:

•

impermissible radial loads causing shaft to break

•

increased wear in the axis and motor gearings

•

reduction of the service life of the belt

X

Y

X

Y

Fv

Fv

Untensioned: X Tensioned: X = Y