Install the kinetix 5500 servo drive – Rockwell Automation 2198-Hxxx Kinetix 5500 Servo Drives Installation Instructions User Manual

Page 5

Kinetix 5500 Servo Drives 5

Rockwell Automation Publication 2198-IN001C-EN-P - January 2014

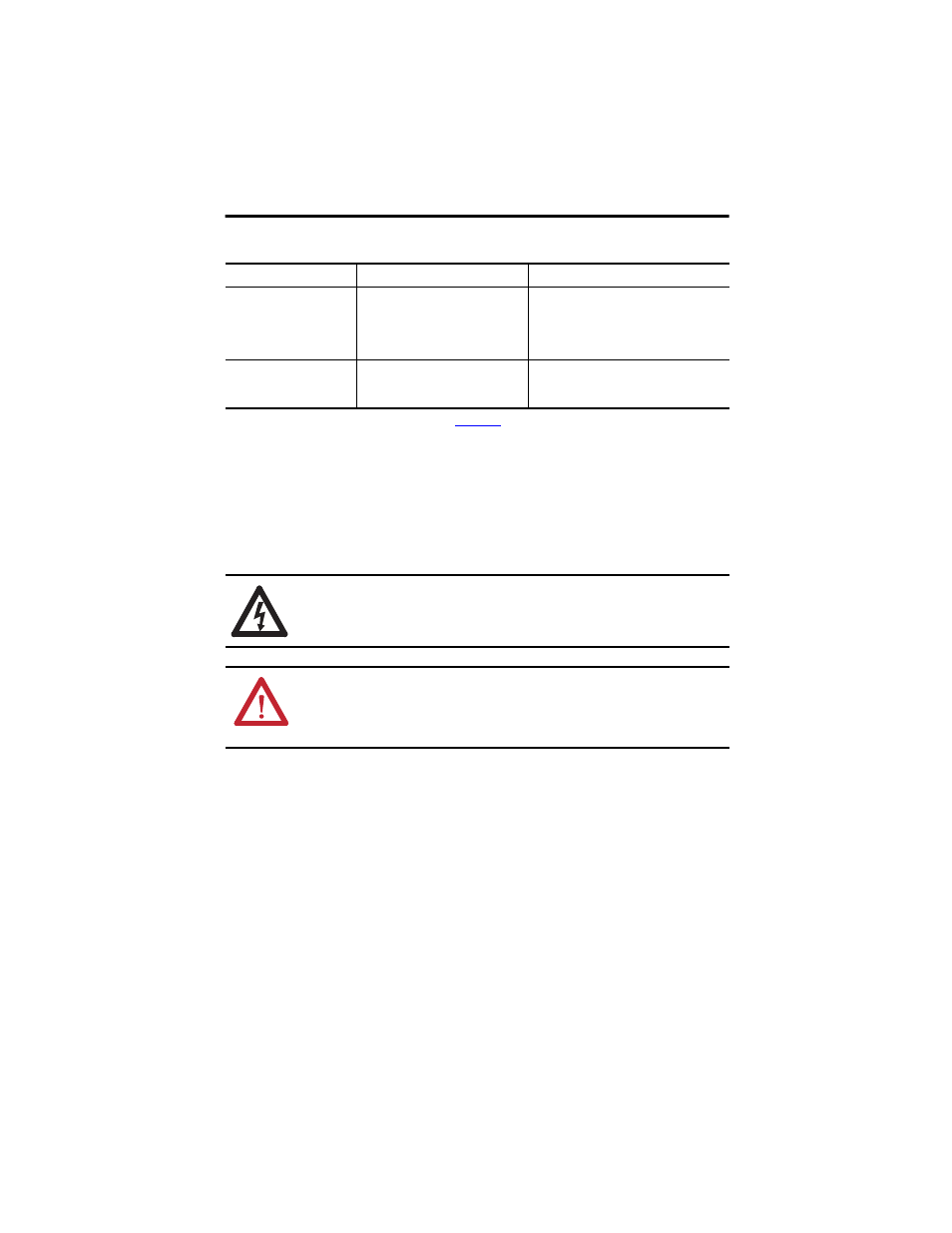

Grounding Screw Configurations

Install the Kinetix 5500 Servo Drive

These procedures assume you have prepared your panel and understand how to bond your

system. For installation instructions regarding equipment and accessories not included here, refer

to the instructions that came with those products.

Ground Configuration

(1)

(1)

Refer to the Kinetix 5500 Servo Drives User Manual, publicat

xample configurations.

Grounding Screw Configuration

Benefits of Configuration

Grounded (wye)

Both screws installed

(default setting)

• UL and EMC compliance

• Reduced electrical noise

• Most stable operation

• Reduced voltage stress on components and

motor bearings

• B-phase corner ground

• AC fed ungrounded

Both screws removed

• Helps avoid severe equipment damage when

ground fault occurs

• Reduced leakage current

SHOCK HAZARD: To avoid hazard of electrical shock, perform all mounting and wiring of the

Kinetix 5500 drive prior to applying power. Once power is applied, connector terminals can have

voltage present even when not in use.

ATTENTION: Plan the installation of your system so that you can perform all cutting, drilling,

tapping, and welding with the system removed from the enclosure. Because the system is of the

open type construction, be careful to keep any metal debris from falling into it. Metal debris or

other foreign matter can become lodged in the circuitry and result in damage to components.