0 overview, 1 diameter effects on surface speed – Rockwell Automation 9329 Drive Application Software User Manual

Page 8

FM – Inertia Compensation

Drive Application Software – page 8 of 30

3.0 Overview

Diameter calculation is the process by which a dynamically changing roll diameter is

mathematically calculated during machine operation. In center driven winding and unwinding

applications, the actual diameter of the driven section changes as product is wound about the axis

or unwound from the axis. As the diameter of the driven section changes it is necessary to

change the axial speed and torque in order to maintain constant surface speed and tension on the

product. Diameter calculation can also be used to calculate the change in total reflected inertia.

This is typically used to profile the speed loop gain and in inertia compensation.

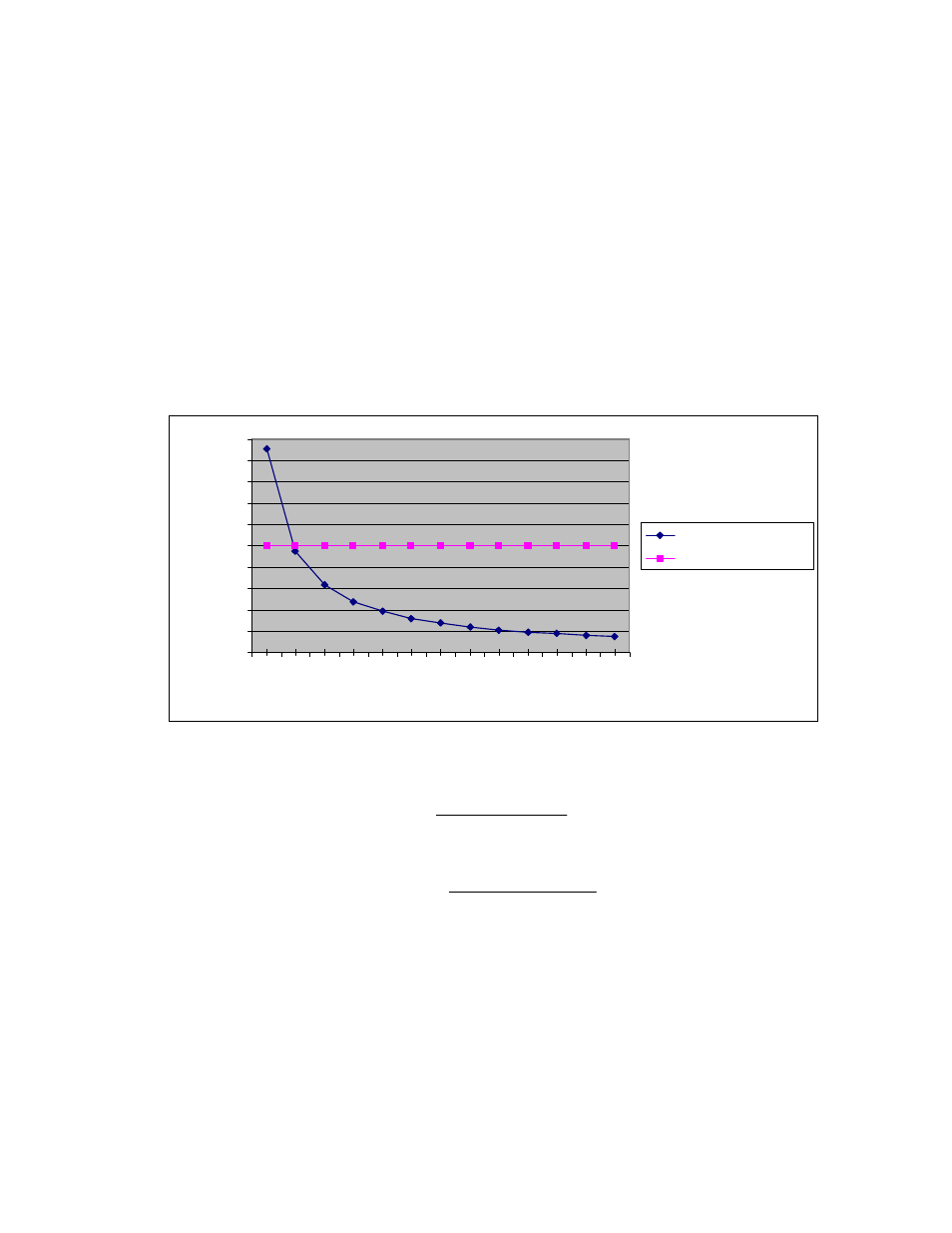

3.1 Diameter effects on surface speed

If the rotational speed of the driven section is kept constant, the surface speed will increase

as the diameter of the section increases. To maintain constant surface speed, the rotational

speed must decrease proportional to the increase in roll diameter. If the roll diameter

doubles, the rotational speed must be reduced by half to maintain constant surface speed.

0

200

400

600

800

1000

1200

1400

1600

1800

2000

4

8

12 16 20 24 28 32 36 40 44 48 52

Roll Diameter (in)

Speed

Motor Speed (Rpm)

Surface Spd (Fpm)

*GearRatio

er(ft)*p

RollDiamet

Fpm)

LineSpeed(

(Rpm)

MotorSpeed

12

er(in)

RollDiamet

er(ft)

RollDiamet

=

=