Appendix a, Process line command & status words – Rockwell Automation 9329 Drive Application Software User Manual

Page 26

FM – Inertia Compensation

Drive Application Software – page 26 of 30

Appendix A -

Process Line Command & Status Words

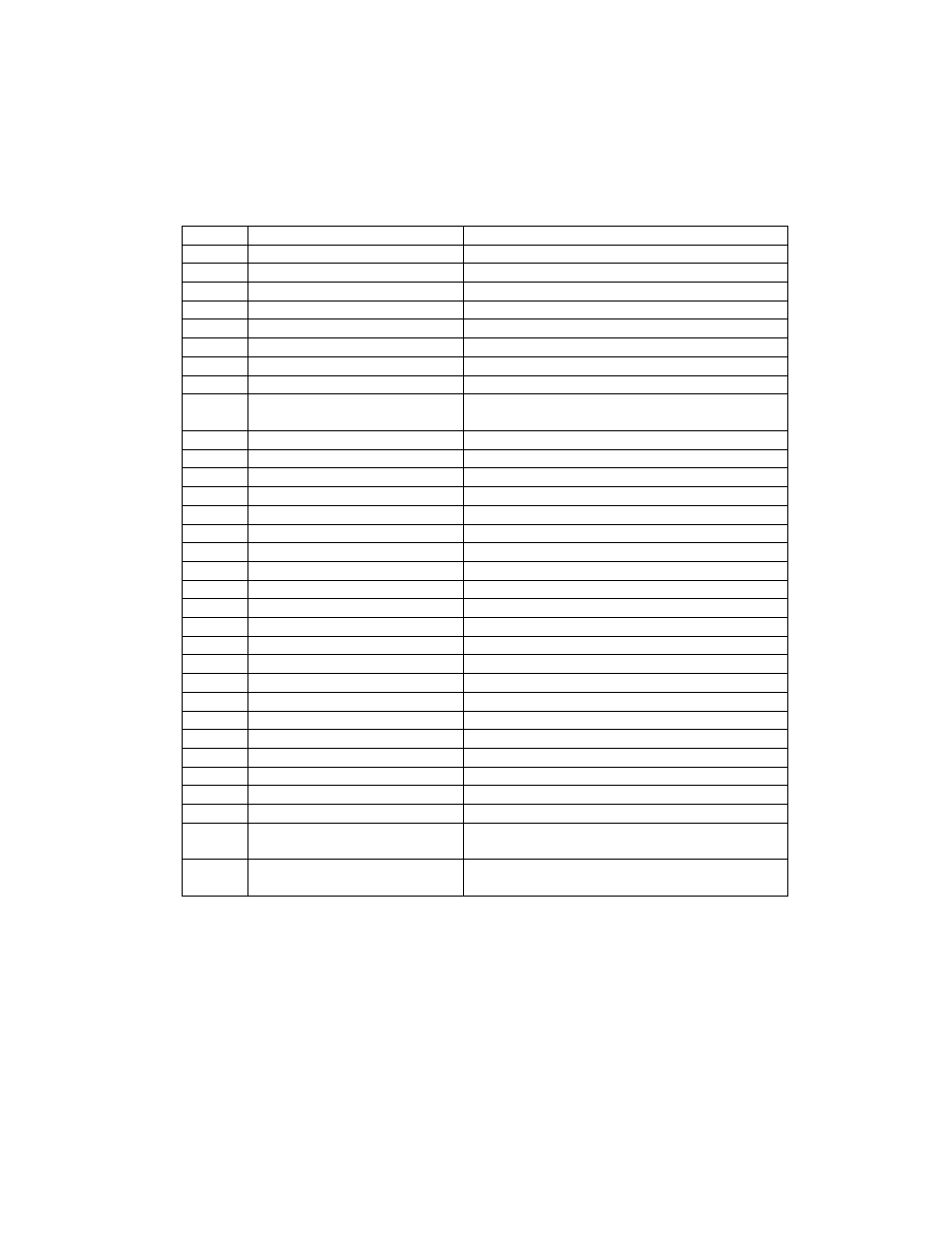

The following table is a functional list of the Process Line command word

[wDLx_DrvCmmdProcLn]

Bit

Input Signal

Description

00

Clear Fault

Clear all Faults

01

Run (2 Wire)

1 = Start, transition to 0 = Stop

02

Reserved

03

Coast Stop

not supported in rev 110101

04

Jog Forward

Jog in Forward direction

05

Jog Reverse

Jog in Reverse direction

06

Reverse Rotation (Under Wind)

Under wind selection

07

Tension Control Enable

Activates selected mode of Tension Control

08

Stall Tension

User determines how and when to activate

Stall Tension

09

Tension Control

Selects Tension Control Mode - Tension

10

Torque Control

Selects Tension Control Mode - Torque

11

Dancer Control

Selects Tension Control Mode - Dancer

12

Torque Trim

Selects Trim type – Torque is trimmed

13

Speed Trim

Selects Trim type – Speed is trimmed

14

Draw Trim Off

Zeros the Draw trim signal

15

Torque Follower Control

Special Control mode for torque follower

16

Diam Preset 1

Commands preset 1 for Diam Calc

17

Diam Preset 2

Commands preset 2 for Diam Calc

18

Diam Preset 3

Commands preset 3 for Diam Calc

19

Diam Preset Increase

Manual increase for Diameter Calc

20

Diam Preset Decrease

Manual decrease for Diameter Calc

21

Diam Calc Increase Enable

Releases Diameter Clac for Increase

22

Diam Calc Decrease Enable Releases Diameter Calc for Decrease

23

Reserved

24

Reserved

25

Reserved

26

Reserved

27

Reserved

28

Reserved

29

Torque Mem Enable

Memorizes running torque

30

Torque Mem Boost Enable

Boosts the memorized torque by user set

percentage.

31

Torque Mem Knife Cut

Boosts the memorized torque by user set

percentage.