Rockwell Automation 9329 Drive Application Software User Manual

Page 14

FM – Inertia Compensation

Drive Application Software – page 14 of 30

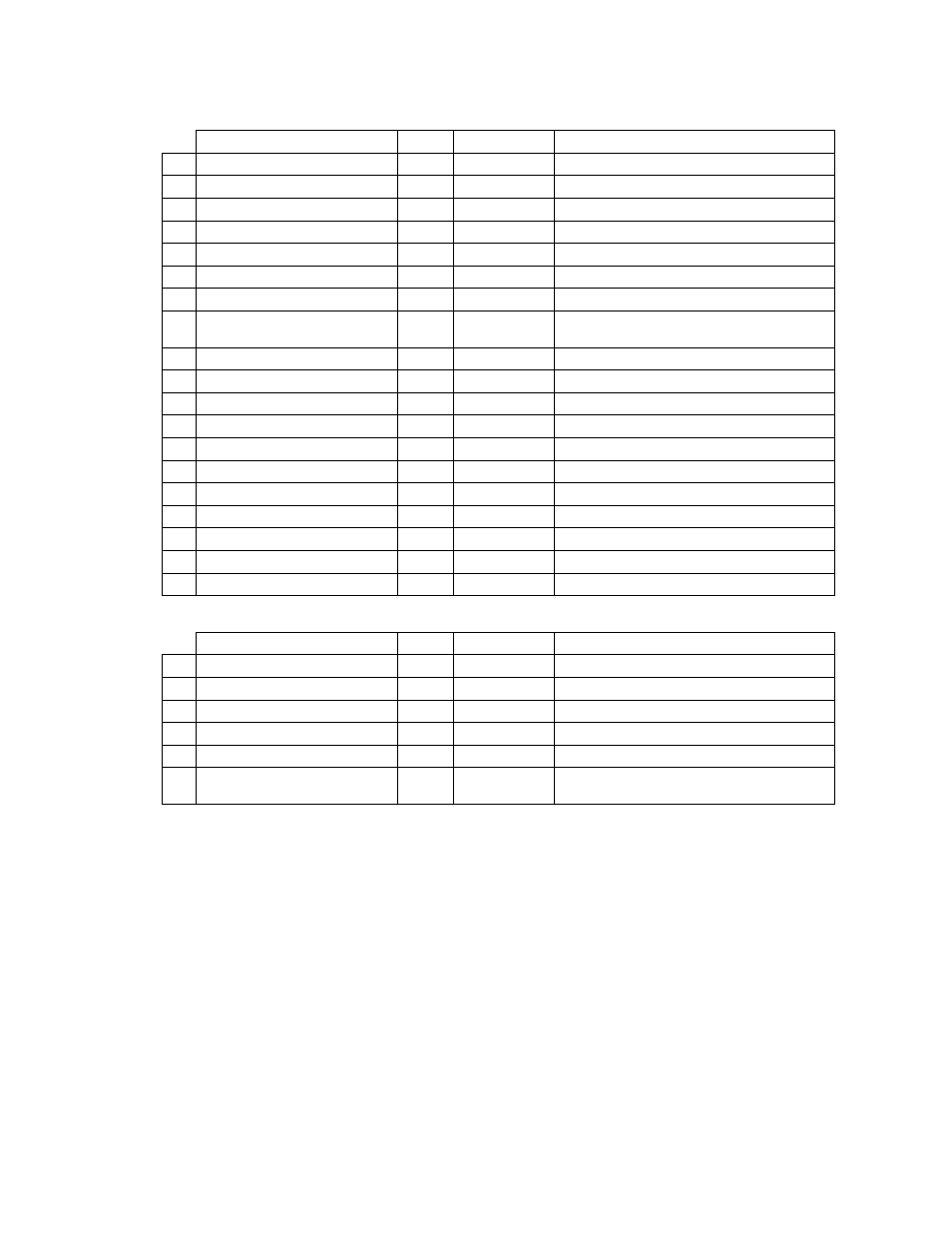

Input Parameters

Name

Type

Range

Description

1 CalcEnbl

BOOL

0 to 1

Enable the Diameter Calculation

2 CalcEnblThresh_FPM

REAL

0 to 50

Diameter Calc low speed thresh hold

3 CalcUpdate_Rev

REAL

1 to 200

Number of revolutions per length count

4 SpeedLine_FPM

REAL

+/- 5000

Line Speed

5 SpeedMotor_RPM

REAL

+/- 7200

Actual motor speed

6 GearRatio

REAL

1 to 100

Motor RPM / Roll RPM

7 DiamMinEC_in

REAL

0 to FR

Minimum diameter Empty Core

8 DiamFR_in

REAL

MinEC to

500

Full Roll diameter

9 DiamMeasEnbl

BOOL

0 to 1

Use DiamMeas value for actual Diam

10 DiamMeasInput

REAL

NA

Measured diameter input (Raw data)

11 DiamMeasMin_DC

REAL

NA

Raw data minimum

12 DiamMeasMax_DC

REAL

NA

Raw data maximum

13 DiamMeasMin_in

REAL

0 to 500

Actual diameter at DiamMeasMin_DC

14 DiamMeasMax_in

REAL

0 to 500

Actual diameter at DiamMeasMax_DC

15 yDiamPresetCmmd

BOOL

0 to 1

Preset command from DiamPreset

16 yDiamPresetVal_in

REAL

0 to 500

Preset value form DiamPreset

17 DiamRate_inRev

REAL

0.00 to 1

Max allowed diameter rate of change

18 DiamIncEnbl

BOOL

0 to 1

Allow diameter calc to increment

19 DiamDecEnbl

BOOL

0 to 1

Allow diameter calc to decrement

Return Parameters

Name

Type

Range

Description

1 DiamCalc_in

REAL

0 to 500

Actual calculated diameter

2 RadiusCalc_ft

REAL

0 to 21

Actual calculated radius

3 BuildUpRatio

REAL

1 to 20

Ratio of actual diameter to min core

4 BuildUpRatioRec

REAL

0.05 to 1

(1 / BuildUpRatio)

5 DiamMeas_in

REAL

0 to 500

Scaled value of measured diameter

6 Constant_RPMperFPM

REAL

NA

Scaling constant FPM to minimum

empty core RPM

4.4.1 CalcEnbl

The CalcEnbl input enables the diameter calculator. When the input is low, the

DiamCalc_in output will maintain its last value, unless the Measured Diameter Enable

input parameter (DiamCalc – In9) is true. If a preset is commanded, the DiamCalc_in

output will be updated to the preset value. When the input is high, the DiamCalc_in

output will be calculated based on line speed and the number of roll rotations. If the

line speed input is below CalcEnblThresh_FPM, the DiamCalc_in output will be held

at last value, regardless of the CalcEnbl state.

Usage – This input should be set high when the section is in run and the line speed

input represents roll surface speed (e.g. web tension control is on (Dancer / Tension /

Torque). The diameter calculator is typically disabled if some form of tension control

is not active.