Maintenance, Crimp settings – Rockwell Automation 2090-Series Circular-DIN Connector Kits, Flange Kits, and Crimp Tools User Manual

Page 7

Rockwell Automation Publication 2090-IN042A-EN-P - May 2011

7

Maintenance

Keep the indenter tips free from abrasion and soiling. Use an air gun to remove

any dirt particles. Wipe down the crimp tool with a clean dry cloth.

Crimp Settings

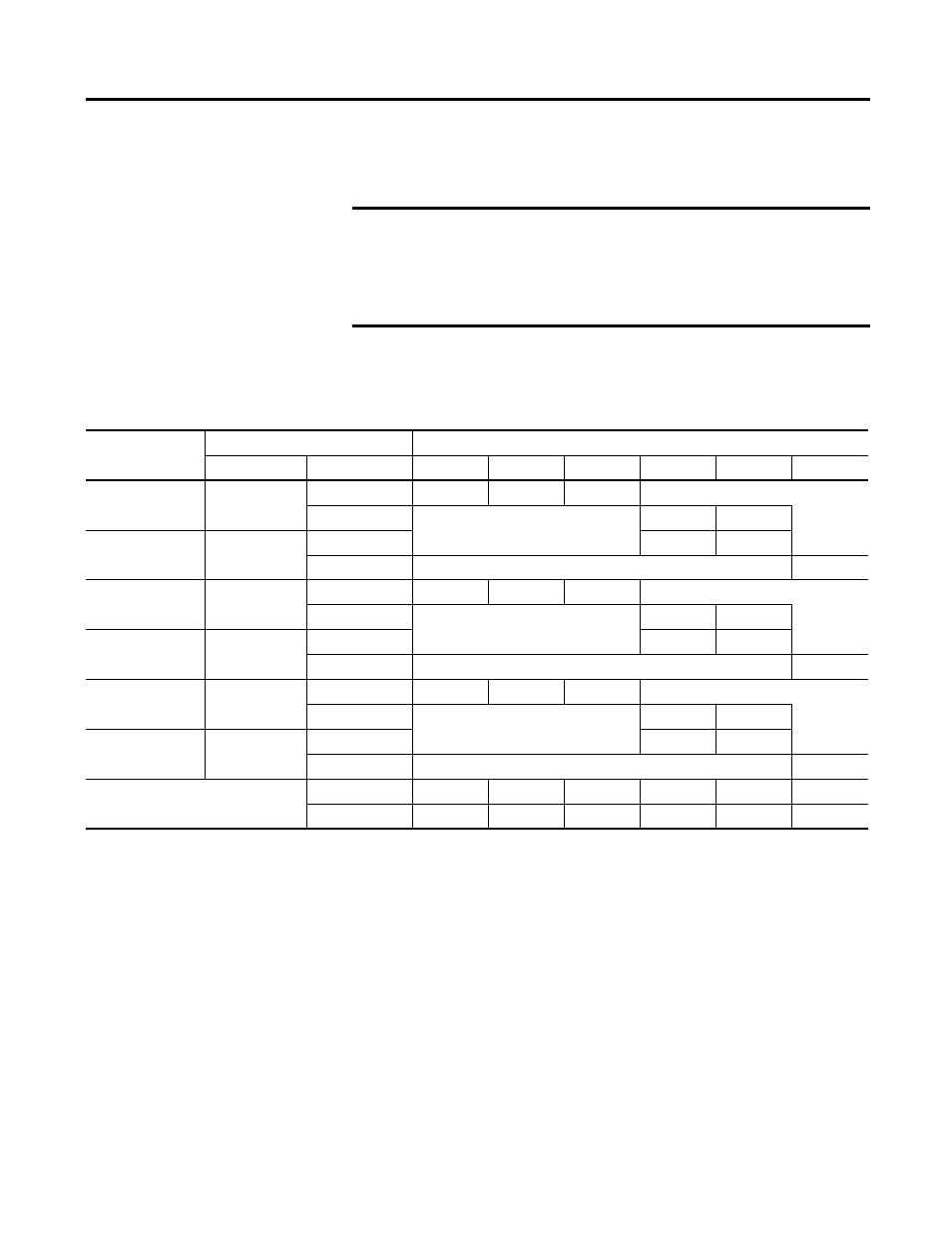

Table 1 - Settings Matrix for Hand Crimp Tool

IMPORTANT

We strongly recommend the following:

•

Do not use any rinsing solutions.

•

Do not lubricate.

•

Do not try to repair.

•

Do not disassemble.

Contact Type

(1)

Positioning Insert

Wire Size, mm

2

(AWG)

(5)

Version

(3)

Color Code

(4)

1.5 (16)

2.5 (14)

4.0 (12)

6.0 (10)

10 (8)

16 (6)

60.042.11

010

Blue

2

3

4

Green

4

6

60.043.11

010

Blue

4

6

Green

8

60.225.11

010

Blue

2

3

4

Green

4

6

60.227.11

010

Blue

4

6

Green

8

61.039.11

61.074.11

010

Blue

2

3

4

Green

4

6

61.040.11

61.075.11

010

Blue

4

6

Green

8

Extraction Force (pull test) [N]

(2)

Setpoint

150

230

310

360

380

–

Actual Value

>250

>370

>600

>850

>1200

>1700

(1) The contacts are included in small bags in the connector and extension kits. Match the number on the bag of contacts to the number in the contact type column.

(2) The values serve as reference only and must be verified with a pull test according to BS EN 60352-2, Table 4, using the actual wire.

(3) The contact type determines which locator version to use. Match the contact type number to the locator version number.

(4) For positioning inserts with two color codes, match the color code to the wire size.

(5) Match the wire size and crimp value to an available contact type to determine the locator version. The crimp values are labeled on the crimp setting dial.