Setting the crimp value – Rockwell Automation 2090-Series Circular-DIN Connector Kits, Flange Kits, and Crimp Tools User Manual

Page 15

Rockwell Automation Publication 2090-IN042A-EN-P - May 2011

15

Setting the Crimp Value

and

21

for crimp depth setting and locator selection. The

values in the table are for standard fine stranded copper wires. The values serve as

reference only and must be verified with a pull test according to

(Solderless Connections. Crimped Connections. General

Requirements, Test Methods and Practical Guidance), Table 4, using the actual

wire.

1. Loosen the adjustment wheel setscrew.

2. Set the crimp value by turning the adjustment wheel until the digital

display shows the required value.

Note: Turn the adjustment wheel clockwise to reduce the crimp value, and

counterclockwise to increase the crimp value.

3. Use an Allen wrench to tighten the adjustment wheel setscrew to save the

settings.

4. If necessary, pull up on the locator until the spring-loaded cartridge that is

locked in place is released.

5.

and

21

to determine the correct locator selection.

6. Turn the locator to align the desired locator cartridge with the crimp

indenters, then press in the locator cartridge until it snaps into place.

IMPORTANT

For accuracy when setting the crimp value, always turn the adjustment

wheel from a larger number to the actual setting. For example, turn the

adjustment wheel up to 2.10 mm and then turn the adjustment wheel

down to 2.00 mm. Do not start at 1.90 mm and turn the adjustment wheel

up to 2.00 mm.

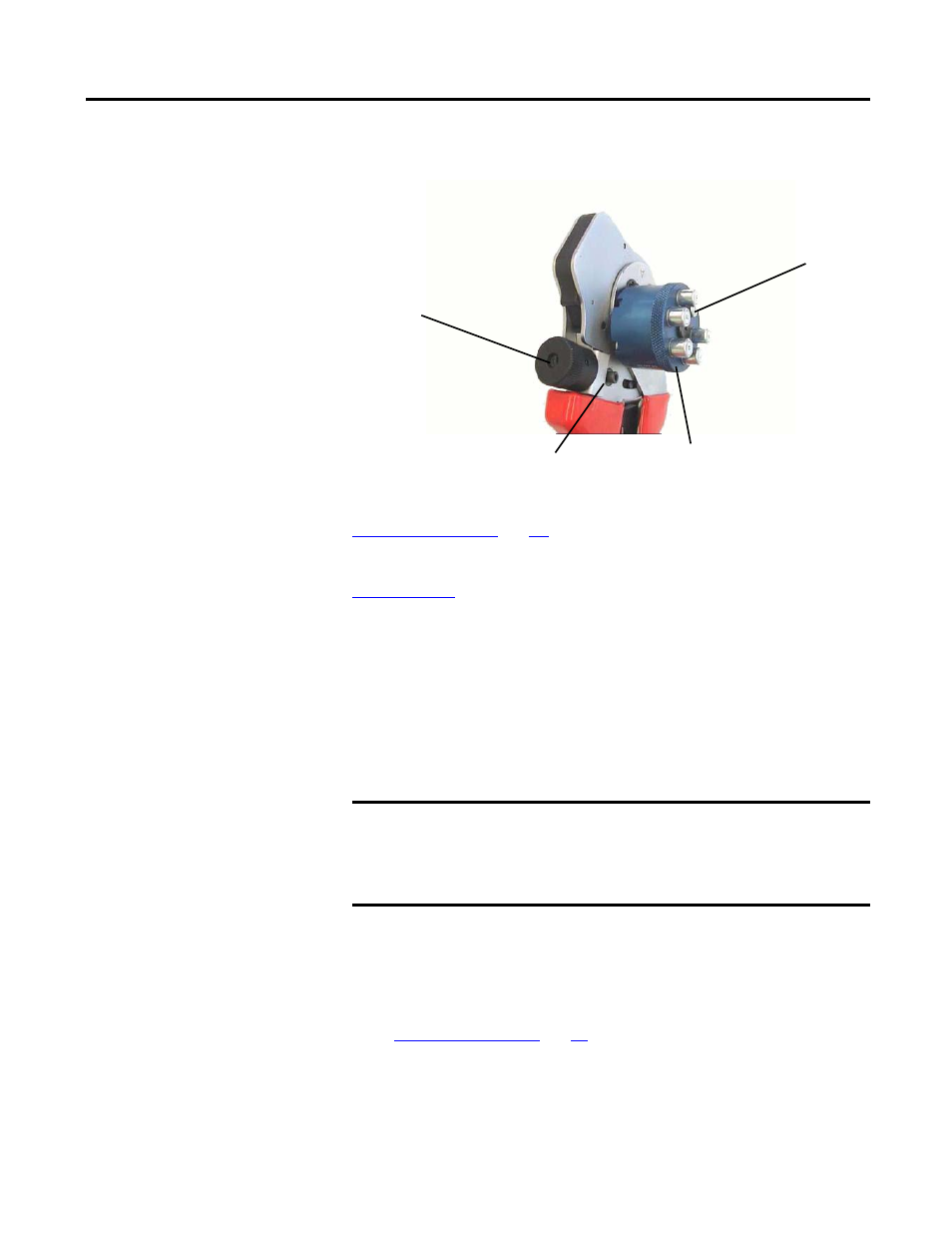

Turn Locator Until Desired Cartridge

is Positioned Over Crimp Indenters

Adjustment Wheel

Setscrew

Press in

Locator

Cartridge

Turn the

Adjustment

Wheel to

Set Crimp

Value