Panel cutout dimensions, Mount the c200, c300, or c600 terminal in a panel – Rockwell Automation 2711C-xxxx PanelView Component HMI Terminals Installation Instructions User Manual

Page 10

10 PanelView Component HMI Terminals

Publication 2711C-IN001H-EN-P - July 2014

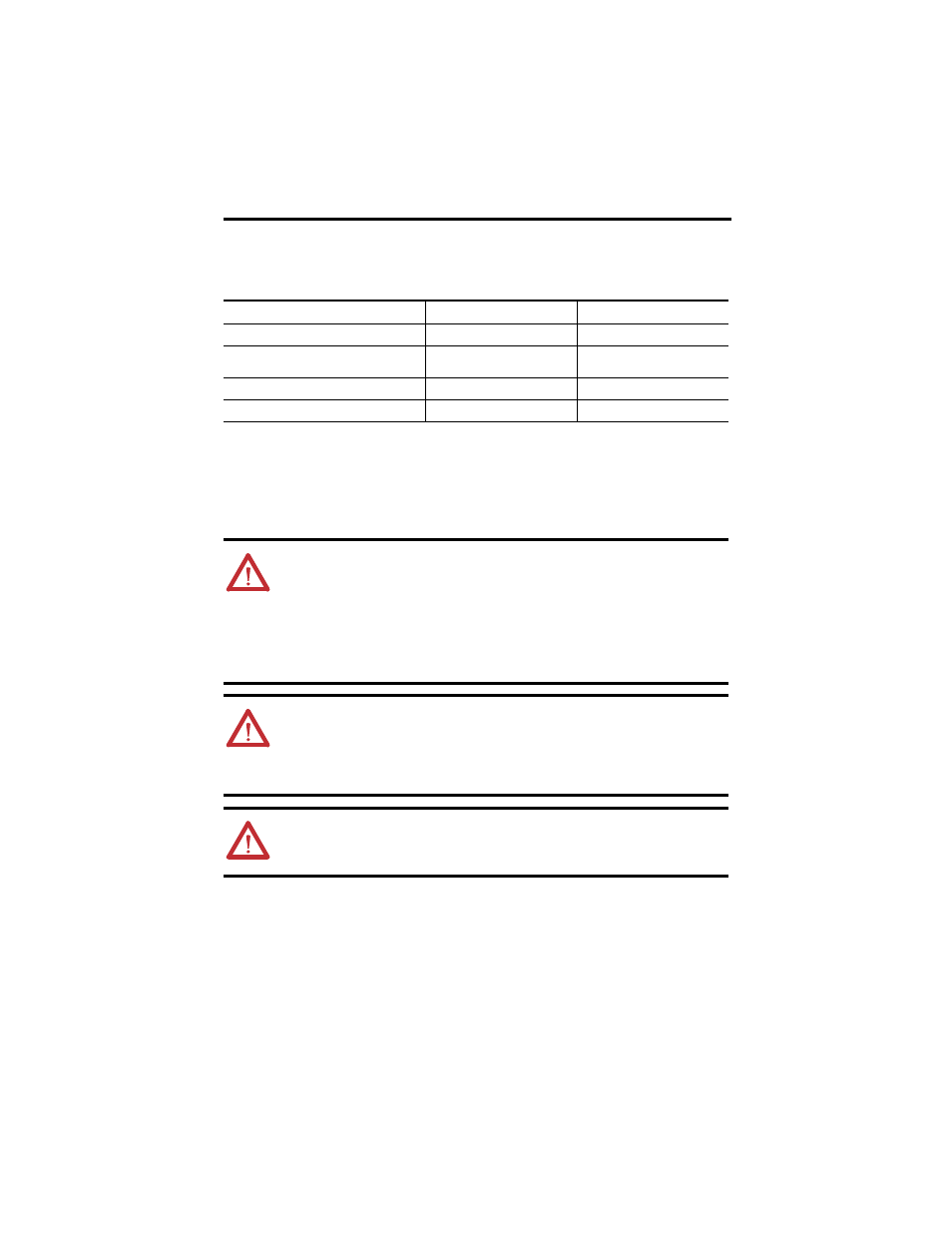

Panel Cutout Dimensions

Use the template shipped with your terminal to mark the cutout dimensions.

Mount the C200, C300, or C600 Terminal in a Panel

PanelView Component C200, C300, and C600 terminals install easily in a panel without any tools or

hardware. The terminals have panel clamps that automatically latch when the terminal is pushed into the

panel opening.

Follow these steps to mount the terminal in a panel.

1. Cut an opening in the panel using the template shipped with the terminal.

2. Make sure the sealing gasket is properly positioned on the terminal.

This gasket forms a compression type seal. Do not use sealing compounds.

3. Place the terminal in the panel cutout.

PanelView Component Terminal

Height, Approx., mm (in.)

Width, Approx., mm (in.)

C200 Function Key and C300 Touch

64.0 ± 1.0 (2.52 ± 0.04)

99.0 ± 1.0 (3.90 ±0.04)

C200 and C300 Keypad

C400 Touchscreen and function keys

99.0 ± 1.0 (3.90 ± 0.04)

119.0 ± 1.0 (4.69 ±0.04)

C600 Touch

135.0 ± 1.0 (5.31 ± 0.04)

189.0 ± 1.0 (7.44 ±0.04)

C1000 Touch

231.0 ± 1.0 (9.09 ± 0.04)

289.0 ± 1.0 (11.38 ±0.04)

ATTENTION: Disconnect all electrical power from the panel before making the panel cutout.

• Make sure the area around the panel cutout is clear.

• Take precautions so metal cuttings do not enter any components already installed in the

panel.

• Failure to follow these instructions may result in personal injury or damage to panel

components.

WARNING: If you connect or disconnect the serial cable with power applied to this module or

the serial device on the other end of the cable, an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

WARNING: When used in a Class I, Division 2, hazardous location, this equipment must be

mounted in a suitable enclosure with proper wiring method that complies with the governing

electrical codes.