Encoders, Differential encoder wiring – Rockwell Automation 1746-HSCE High-Speed Counter Module Installation Instructions User Manual

Page 15

High-Speed Counter Module 15

Publication 1746-IN011C-EN-P - April 2005

Encoders

The wiring diagrams on the following pages are provided to support the

Allen-Bradley encoders you may already have. Differential encoders provide the

best immunity to electrical noise.

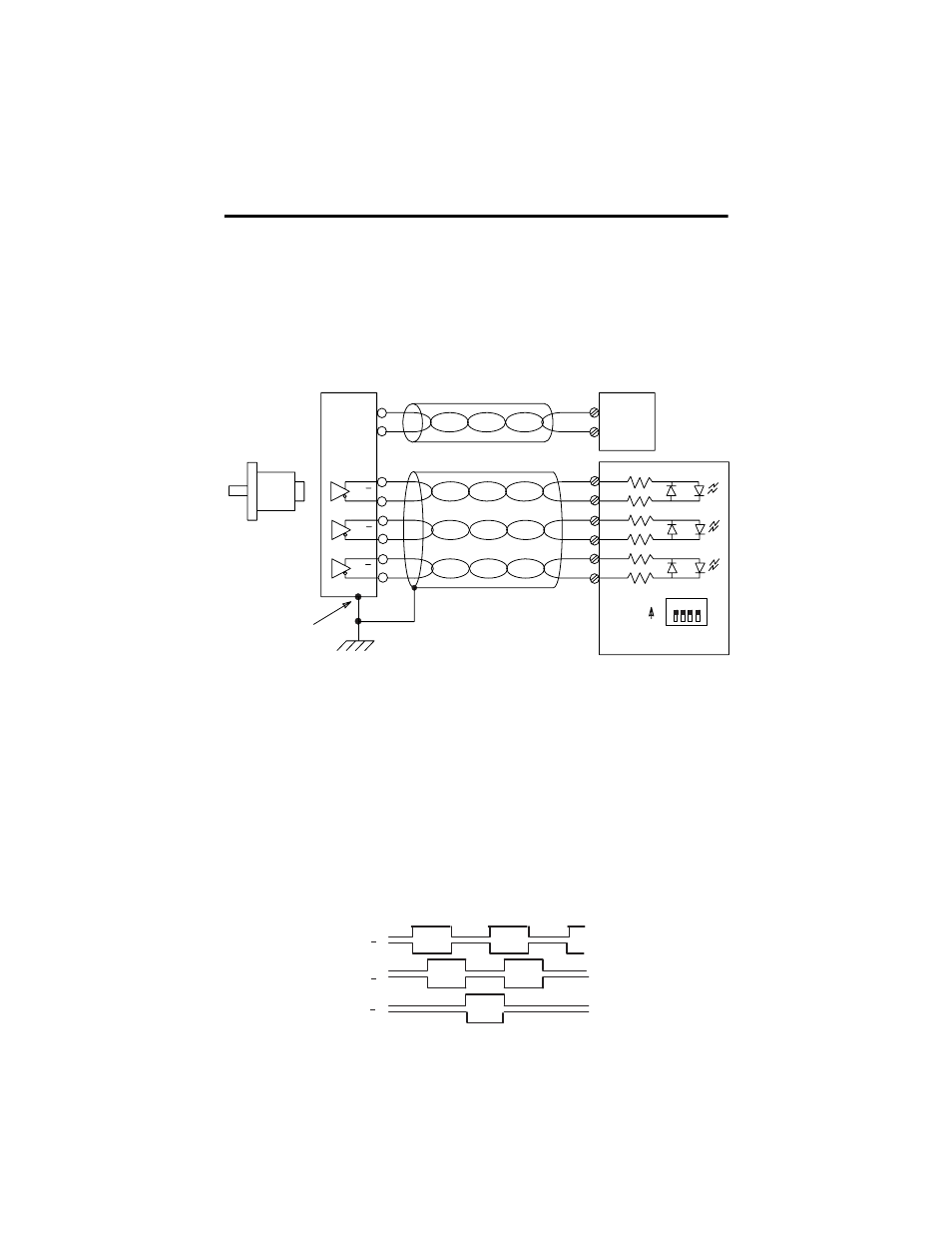

Differential Encoder Wiring

Differential Encoder Output Waveforms

The illustration below shows the different encoder output waveforms. If your

encoder matches these waveforms, the encoder signals can be directly connected to

the associated screw terminals on the module. For example, the A lead from the

encoder is connected to the module’s A+ screw. If your encoder does not match

these waveforms, some wiring modifications may be necessary. Refer to the

High-Speed Counter Module User Manual, publication 1746-6.5 for a description of

these modifications.

A

A

B

B

Z

Z

A(+)

A(-)

B(+)

B(-)

Z(+)

Z(-)

1 2 3 4

+ V D C

COM

VS

GND

cable

(1)

Belden 9503 or equivalent

305m (1000ft) max length

Power

Supply

Allen-Bradley

845H Series

differential

encoder

encoder connector

Earth

Shield

(2)

Module Inputs

SW1

ON

OFF

(all switches

(1) Refer to your encoder manual for proper cable type and length.

(2) Due to the topology of the module’s input circuits, terminating the shield at the encoder end provides the highest immunity

to EMI interference. Connect EARTH ground directly to the encoder connector housing.

A

A

B

B

Z

Z