Wire the finger-safe terminal block, Wire size and terminal screw torque – Rockwell Automation 1769-IF16C Conpact High Density Analog Current Input Module User Manual

Page 14

14 Compact High-density Analog Current Input Module

Publication 1769-IN085A-EN-P - August 2008

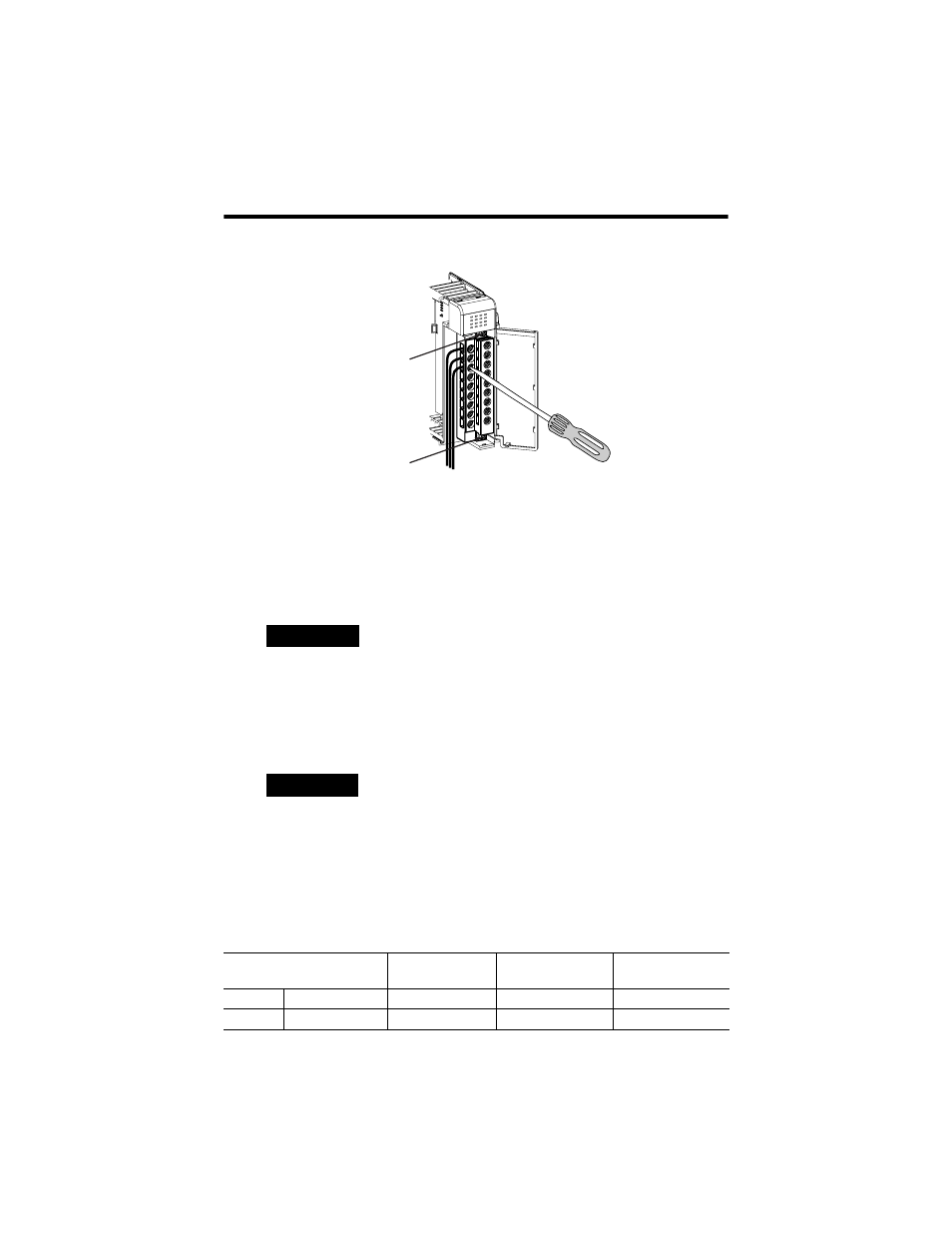

Wire the Finger-safe Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Loosen the terminal screws to be wired.

2. Route the wire under the terminal pressure plate.

You can use the bare wire or a spade lug. The terminals will accept a

6.35 mm (0.25 in.) spade lug.

3. Tighten the terminal screw making sure the pressure plate secures the wire.

Recommended torque when tightening terminal screws is 0.68 N•m

(6 in•lbs).

Wire Size and Terminal Screw Torque

Each terminal accepts two wires with the following restrictions:.

TIP

The terminal screws are non-captive. Therefore, it is possible

to use a ring lug [maximum 1/4 inch o.d. with a 0.139 inch

minimum i.d. (M3.5)] with the module.

TIP

If you need to remove the finger-safe cover, insert a screw

driver into one of the square wiring holes and gently pry the

cover off. If you wire the terminal block with the finger-safe

cover removed, you will not be able to put it back on the

terminal block because the wires will be in the way.

Wire Type

Wire Size

Terminal Screw

Torque

Retaining Screw

Torque

Solid

Cu-90 °C (194 °F)

#14…#22 AWG

0.68 N•m (6 in•lb)

0.46 N•m (4.1 in•lb)

Stranded

Cu-90 °C (194 °F)

#16…#22 AWG

0.68 N•m (6 in•lb)

0.46 N•m (4.1 in•lb)

Upper Retaining Screw

Lower Retaining Screw