Connect equipment grounding conductor – Rockwell Automation 1771-A1B_A2B_A3B_A3B1_A4B SERIES B Universal I/O Chassis Installation Instructions User Manual

Page 11

Universal I/O Chassis

11

Publication 1771ĆIN075A-EN-P - March 2002

Connect Equipment Grounding Conductor

equipment

grounding

conductors

ground

lug

bolt

star

washer

Grounding electrode

conductor to grounding

electrode system

tapped hole

ground bus

ground bus

mounting

13271

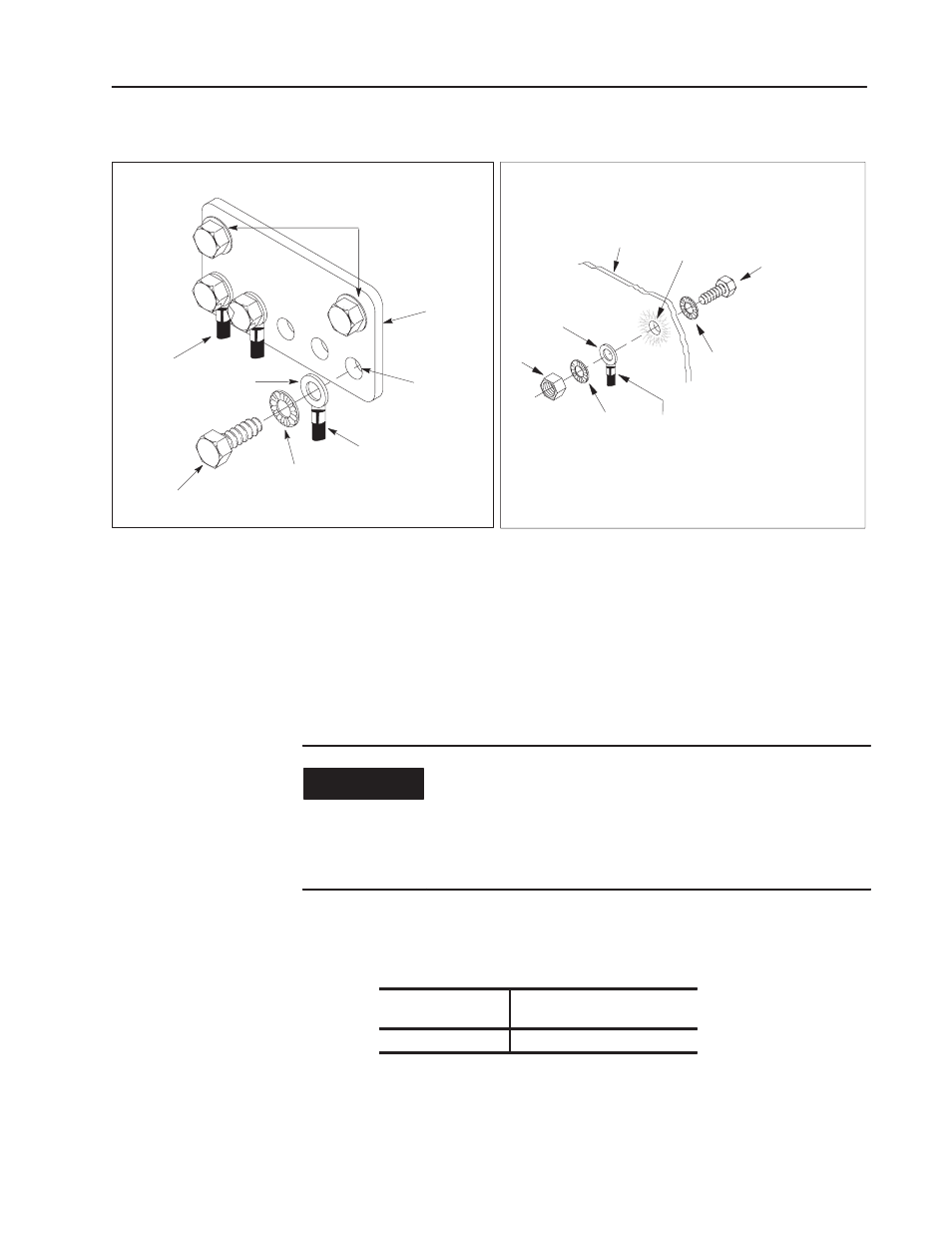

Connecting Equipment Ground Conductor to a Ground Bus

10020

Connecting Equipment Ground Connector to an Enclosure Wall

Enclosure

Wall

Equipment-Grounding

Conductor

Scrape

Paint

Star

Washer

Nut

Ground

Lug

Scrape paint on enclosure wall

and use a star washer.

Bolt

Functional Ground

•

use 2.54cm (1in.) copper braid or 10.0mm

2

(8 AWG) copper wire to connect

each chassis, the enclosure and a central ground bus mounted on the

backĆpanel

•

use a steel enclosure to guard against electromagnetic interference (EMI)

•

make sure the enclosure door viewing window is a laminated screen or a

conductive optical substrate (to block EMI)

Protective Earth Ground

•

use a2.5mm

2

(14 AWG) copper wire for the equipment grounding conductors

•

install a bonding wire [2.5mm

2

(14AWG) minimum] for electrical contact

between the door and the enclosure; do not rely on the hinge

IMPORTANT

Do not lay one ground lug directly on top of the other; this

type of connection can become loose due to compression

of the metal lugs.

Place the first lug between a star washer and a nut with a

captive star washer.

After tightening the nut, place the second lug between the

first nut and a second nut with a captive star washer.

Connect an equipment grounding conductor directly from each

chassis to an individual bolt on the ground bus.

For chassis with

Connect the equipment

grounding conductor using

aground stud

the grounding stud