Module calibration chapter 7, Setting channel gain calibration – Rockwell Automation 1771-IXHR , D17716.5.80 HIGH RESOL.THERMOCOUPLE User Manual

Page 41

Module Calibration

Chapter 7

7Ć7

For example, if the observed value was 17, enter –53 [(0 – 17) x 3.0933 =

–53] in signed magnitude binary into the upper byte of the calibration

word for that channel. Enter 10110101 in bits 15–08 of word 20. The

lower byte will remain zero at this time.

6.

Repeat steps 3 through 5 for each of the remaining input channels.

7.

Initiate a write block transfer to send the corrections to the module. The

input value read by the processor should now be 0000 for all channels.

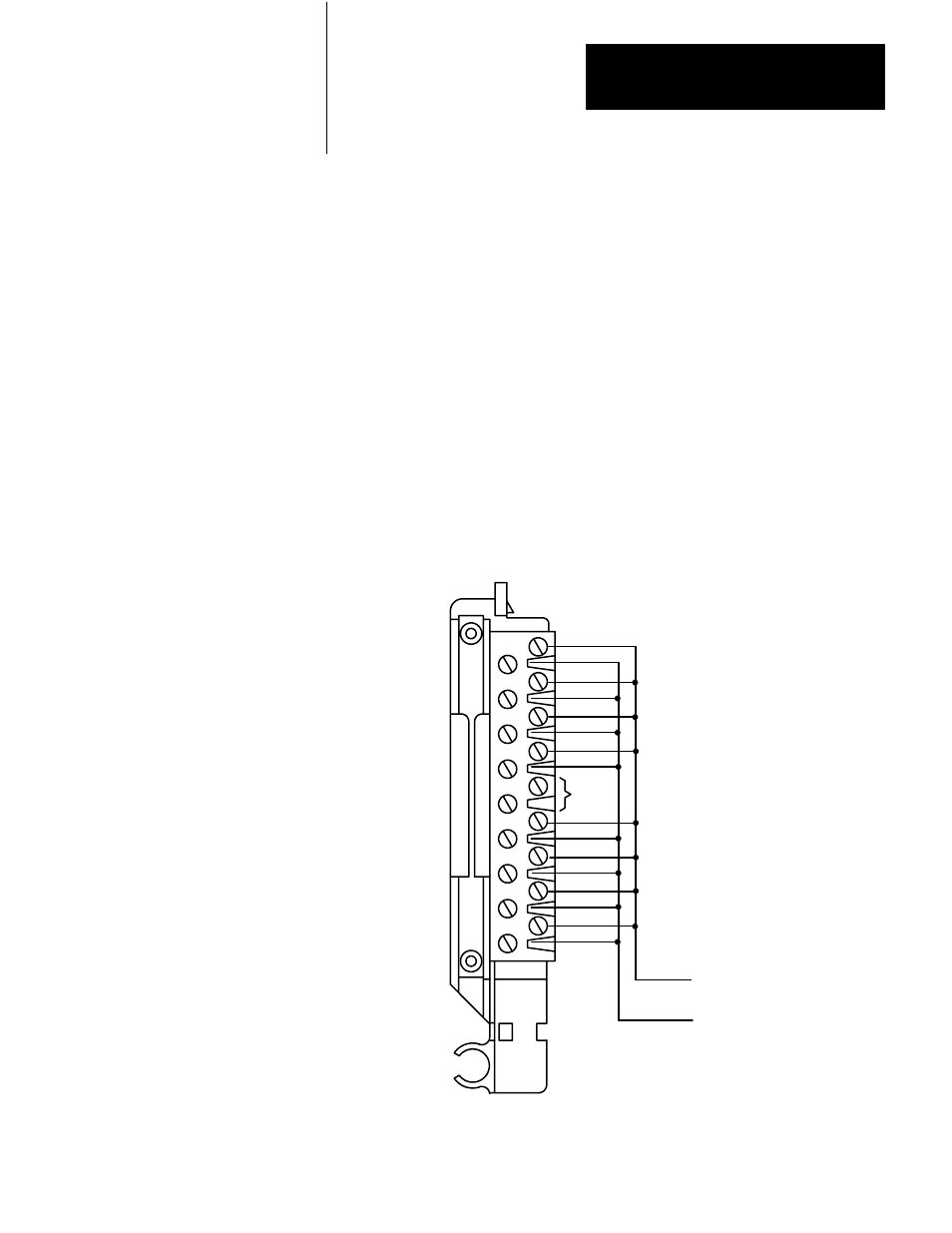

Setting Channel Gain Calibration

1.

Now set the precision voltage source for +100.000 millivolts. Allow

sufficient time (at least 10 seconds) for the input filter and voltage source

to settle.

Figure 7.4

Applying 100.000mV for Gain Calibration

1

Do not

use

18

Input 1 (+ lead)

17

Input 1 (- lead)

16

Input 2 (+ lead)

15

Input 2 (- lead)

14

Input 3 (+ lead)

13

Input 3 (- lead)

12

Input 4 (+ lead)

11

Input 4 (- lead)

10

Not Used

9

Not used

8

Input 5 (+ lead)

7

Input 5 (- lead)

6

Input 6 (+ lead)

5

Input 6 (- lead)

4

Input 7 (+ lead)

3

Input 7 (- lead)

2

Input 8 (+ lead)

1

Input 8 (- lead)

Terminal Identification

Terminal

Function

Wiring Arm

Cat. No. 1771-WI

18

17

16

1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

100.000mV

Apply

+

-

10533-I