Plc-3 program example – Rockwell Automation 1771-IXHR , D17716.5.80 HIGH RESOL.THERMOCOUPLE User Manual

Page 20

Module Programming

Chapter 4

4Ć2

Block transfer instructions with the PLC–3 processor use one binary file in a

data table section for module location and other related data. This is the block

transfer control file. The block transfer data file stores data that you want

transferred to the module (when programming a block transfer write) or from

the module (when programming a block transfer read). The address of the block

transfer data files are stored in the block transfer control file.

The industrial terminal prompts you to create a control file when a block

transfer instruction is being programmed. The same block transfer control file

is used for both the read and write instructions for your module. A different

block transfer control file is required for every module.

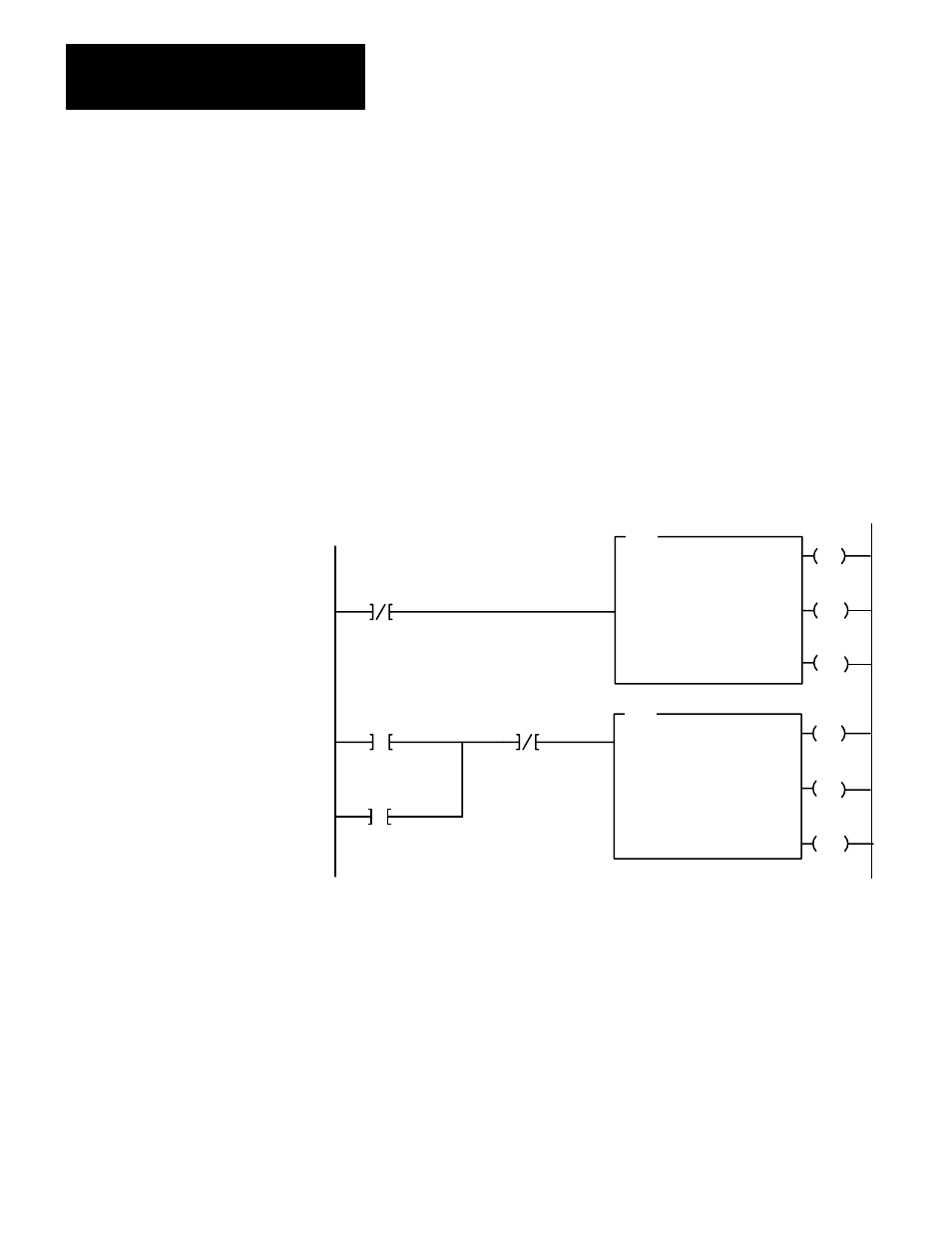

A sample program segment with block transfer instructions is shown in

Figure 4.1, and described below.

Figure 4.1

PLC-3 Family Sample Program Structure

EN

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

DATA:

XXX

X

X = XXXX

XXXX:XXXX

LENGTH:

CNTL:

X

XXXX:XXXX

EN

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

DATA:

XXX

X

X = XXXX

XXXX:XXXX

DN

LENGTH:

CNTL:

X

XXXX:XXXX

Pushbutton

Power-up

Bit

Block Transfer

Read Done Bit

ER

ENABLE

DONE

ERROR

12

15

13

ENABLE

DONE

ERROR

02

05

03

Block Transfer

Write Done Bit

1

2

DN

ER

Program Action

At power–up, the user program examines the BTR done bit in the block transfer

read file, initiates a write block transfer to configure the module, and then does

consecutive read block transfers continuously. The power–up bit can be

examined and used anywhere in the program.

Rungs 1 and 2 - Rungs 1 and 2 are the block transfer read and write

instructions. The BTR enable bit in rung 1, being false, initiates the first

read block transfer. After the first read block transfer, the module

performs a block transfer write and then does continuous block transfer

reads until the pushbutton is used to request another block transfer write.

PLC-3 Program Example