Rockwell Automation 1395 Node Adapter Board User Manual

Page 15

Chapter 3

Functional Description

3-3

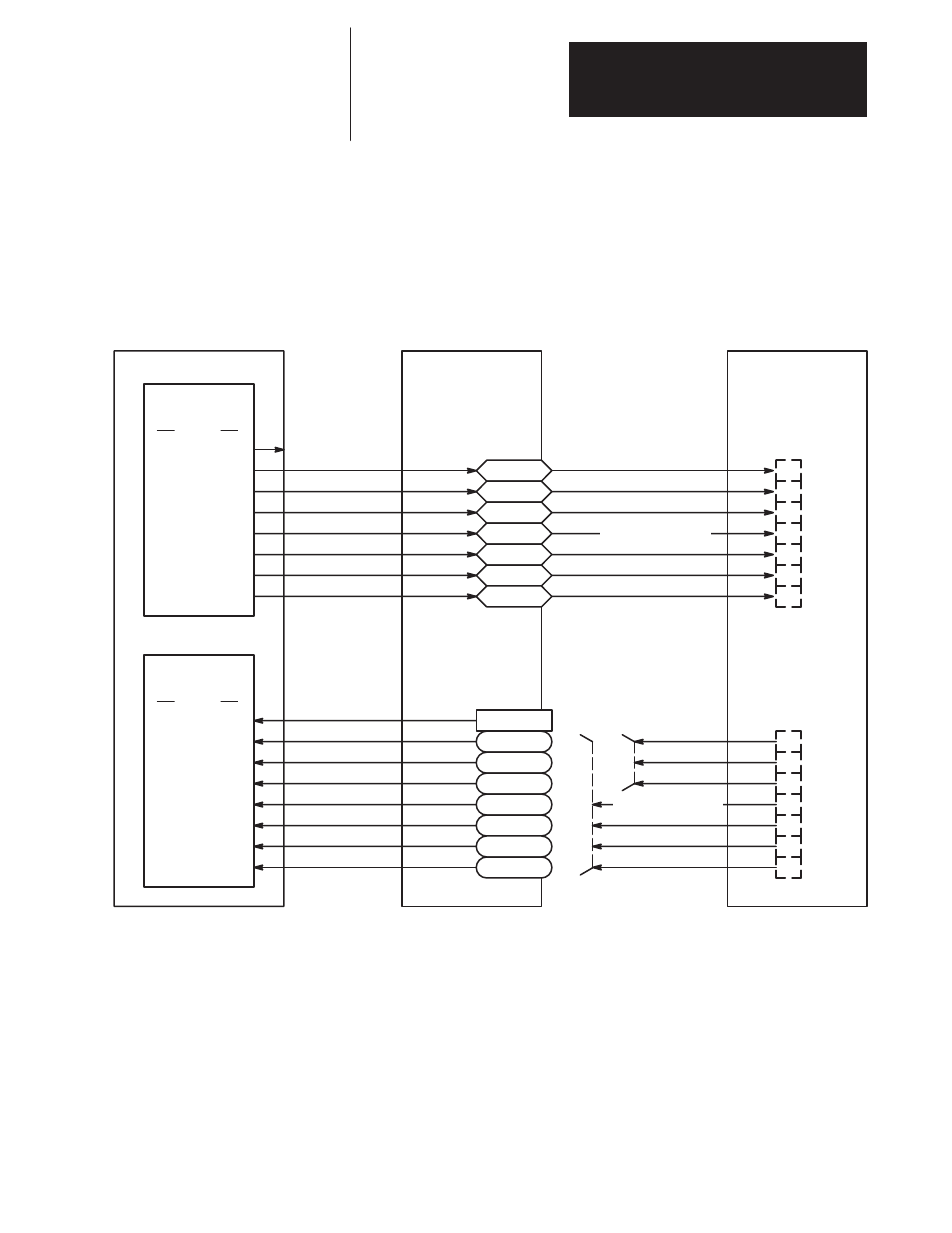

Data required by the drive on a continuously updated basis is sent (to the

drive) using the method of data transfer described above. The rate of data

transfer is determined by the standard conventions for determining the I/O

update interval of the I/O scanner for the particular PLC Controller used.

Figure 3.1

Node Adapter Configuration Variables

Node Adapter Board

300/400

301/401

302/402

303/403

304/404

305/405

306/406

Reserved for

Block Transfer

PLC Controller

Output Image Table

Group Number

Full

Half

0

1

2

3

4

5

6

7

0/4

1/5

2/6

3/7

Input Image Table

Group Number

Full

Half

0

1

2

3

4

5

6

7

0/4

1/5

2/6

3/7

NA Status

350/450

351/451

352/452

353/453

354/454

355/455

356/456

Block Transfer

Port B/A

Port B/A

1

2

3

4

5

6

7

1

2

3

4

5

6

7

User Configurable

Soft Links

Half

Rack

Full

Rack

Sinks

Output

Variables

Input

Variables

Bulletin 1395 Drive

Sources

User Configurable

Soft Links

Discrete PLC Controller I/O Example

Figure 3.2 illustrates an application where the Node Adapter Board has

been setup for a full rack (numbered rack 2) and the 16 bit words for group

1 and 2 are being used by the PLC Controller program for data transfer

with the drive. In this example, the drive has been configured so that the

data coming into source parameter 300 is sent to Logic Cmd 1 (Parameter

150). Information sent to the drive using the 16 bit output word for group 1

of rack 2 must therefore be a 16 bit logic word where the bits are defined

by the description of Parameter 150.