E - doc cleaning and maintenance, Contact resistance, Vacuum interrupter integrity test – Rockwell Automation 1102C-BOx93 Vacuum Contactor (200A) User Manual

Page 6: Wiring, G. ushakow

42052-087

G. Ushakow

N/A

N/A

N/A

42052

1006490

1

INSTRUCTION SHEET

BULLETIN 1102C VACUUM CONTACTOR

CURRENT RATINGS 200A

200V-1500V

2-20-04

Mark Jutz

2-20-04

D. Josef

2-20-04

6

9

REVISION

AUTHORIZATION

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

H

A

B

C

D

E

F

G

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

REFERENCE

SHEET

OF

DWG.

B

DR.

CHKD.

APPD.

DATE

DATE

DATE

±

±

±

ANGLES:

.XXX:

.XX:

THIS DRAWING IS THE PROPERTY OF

THE ALLEN-BRADLEY CO. INC.

AND MAY NOT BE COPIED, USED OR

DISCLOSED FOR ANY PURPOSE EXCEPT

AS AUTHORIZED IN WRITING BY

THE ALLEN-BRADLEY CO. INC.

LOCATION : MILWAUKEE,

WISCONSIN

U.S.A.

SIZE

1

2

3

4

5

6

7

8

E - DOC

Cleaning and Maintenance

1. The vacuum contactor requires no adjustment. Preventative maintenance is recommended on a routine basis, once every twelve

months, dependent upon the environment that the contactor is exposed to. In general, maintenance consists of keeping the device free of

dirt and dust and ensuring the power and control terminals are tight.

2. Maintenance should verify the mechanical operation of the device for freedom of movement. Clean dirt from the surfaces. Pay

particular attention to molded parts and tracking surfaces. Foreign materials on these surfaces should be removed by vacuum or wiping.

Do not use compressed air to remove foreign materials.

ATTENTION:

The following test should be performed using a 50/60 Hz test set. Where the voltage is continuously variable up to at least

20 kV. X-radiation at this level is negligible. However, personnel should not be closer than ten feet to the interrupter and the test cables to

avoid high voltage shock hazards. The contactor should be free of dust and other contaminants before conducting this test.

Contact Resistance

A contact resistance test can be performed using a micro-ohmeter. This test determines the condition of contact surfaces. With the

contactor closed, the resistance across the terminals should be less than 400 micro-ohms. If higher contact resistance values are

measured then a high potential test should be performed, as follows:

1. Disconnect the line and load conductors from the contactor.

2. Connect the leads of the test set across the interrupter terminals with the contactor in the open position.

3. Slowly raise the voltage to 10 KV and hold for 15 seconds.

4. The leakage current should not exceed 5 MA during the test and any tripping of the test set circuit protector during the test should be

repeated two to three times. If it becomes impossible to reach the 10 KV level, then the interrupter needs to be replaced, and should be

replaced by utilizing an Allen-Bradley replacement phase assembly kit.

ATTENTION: Excercise caution while performing high voltage potential tests.

Vacuum Interrupter Integrity Test

1. A high potential test will determine the di-electric strength and condition of the vacuum interrupter. A high potential test should be

performed on each vacuum interrupter phase in sequence and should be performed approximately once every twelve months.

2. The vacuum interrupter integrity test should be performed if the contactor has been known to be exposed to fault conditions - either

phase to phase or phase to ground.

3. When doing this check, make visual inspection for physical evidence of stress, distorted, discolored or cracked interrupters.

4. A contact resistance test can be done as defined below or if preferred a high potential test; di-electric test should be performed as

follows.

(6)

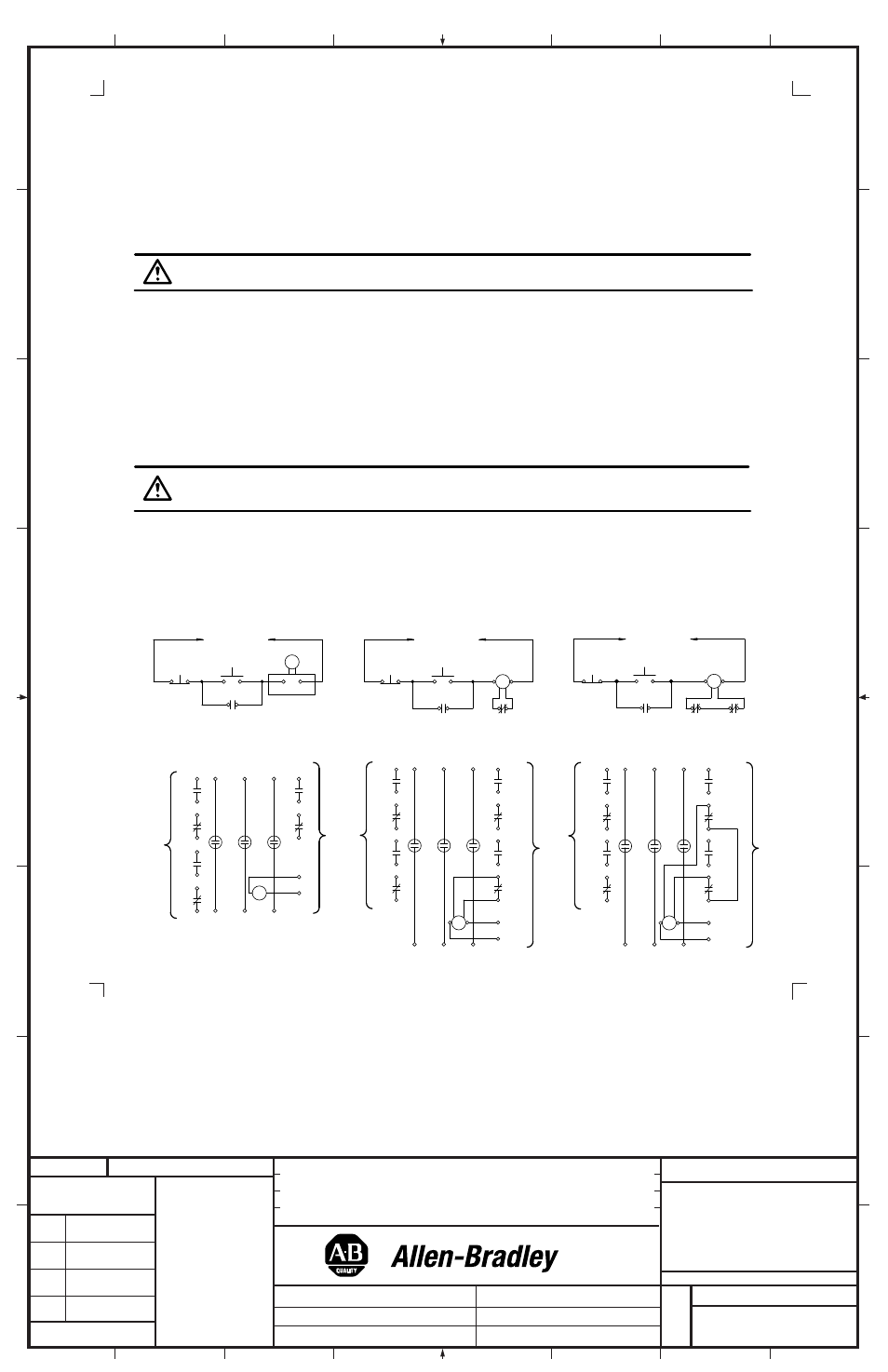

Wiring

T1

T2

T3

(A1)

(A2)

(82)

(81)

O

P

T

IO

N

A

L

(

11

95

C

-N

3

O

R

1

19

5C

-N

4)

M

(74)

(73)

(62)

(22)

(61)

(54)

(21)

(14)

WIRING DIAGRAM

WIRING DIAGRAM

WIRING DIAGRAM

(53)

(13)

L3

L2

L1

(A2)

(A1)

(14)

(13)

M

START

STOP

M

SCHEMATIC

SEPARATE

AC SOURCE

(34)

(33)

M

START

STOP

SCHEMATIC

SCHEMATIC

SEPARATE

125V DC SOURCE

LATE

BREAK

(B2)

(B1)

(46)

(45)

M

(B1)

M

T3

T2

T1

(B2)

(82)

(81)

LATE

BREAK

(74)

(73)

(34)

(33)

(46)

(45)

O

P

T

IO

N

A

L

(

11

95

C

-N

3

O

R

1

19

5C

-N

4)

(62)

(61)

(54)

(22)

(21)

(14)

(53)

(13)

L1

L2

L3

(B1)

T3

T2

T1

(B2)

(82)

LATE

BREAK

M

(81)

(74)

(73)

(34)

(33)

LATE

BREAK

(62)

(61)

(54)

(26)

(53)

(25)

(46)

(45)

(14)

(13)

L1

L2

L3

O

P

T

IO

N

A

L

(

11

95

C

-N

3

O

R

1

19

5C

-N

4)

11

95

C

-N

6

C

O

N

T

R

O

L

P

A

K

11

95

C

-N

5

LATE

BREAK

(B2)

(B1)

M

(34)

(33)

(26)

(25)

(45)

(46)

M

START

STOP

SEPARATE

250V DC SOURCE