Installation instructions, E - doc, Coil replacement instructions – Rockwell Automation 1102C-BOx93 Vacuum Contactor (200A) User Manual

Page 2

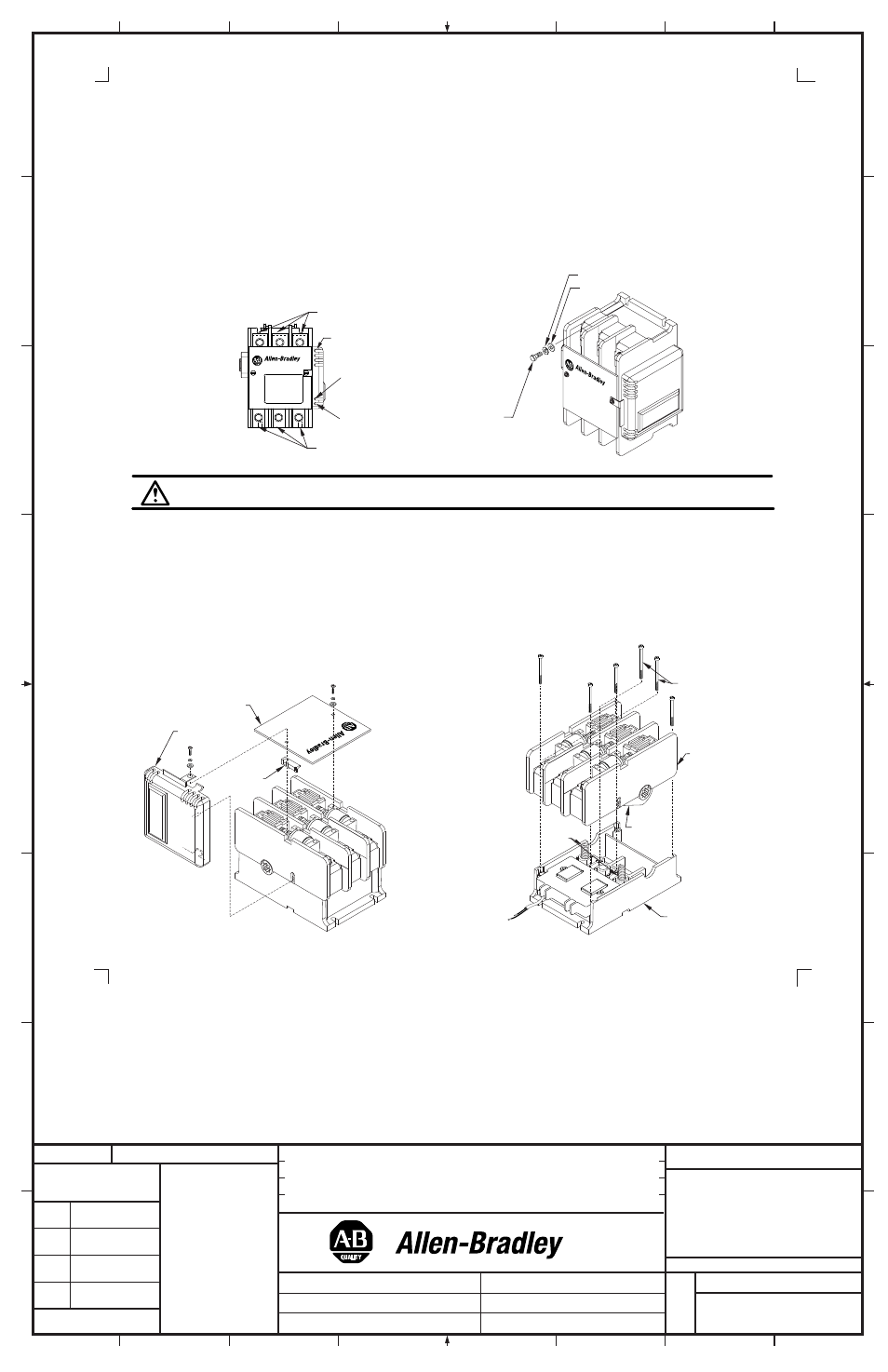

Line Terminals

Control Pak

1/4 Flat

Washer

1/4 Lock Washer

1/4" or 7mm Bolt

Coil

Terminals

Load Terminals

A1

A2

Installation Instructions

The vacuum contactor may be used in any mounting plane. In any non-horizontal mounting plane, the top of the contactor should point up

(so that the label appears right-side up). Care should be taken to insure that the mounting hardware does not warp the mechanism frame. If

the surface of the contactor to which the contactor is mounted is twisted, shims should be used to correct the condition. Any appreciable

degree of end to end twist will result in phase to phase discrepancies and timing of the main contact could cause increased pickup in control

voltage values.

1. Figure 1 illustrates the field terminals for line and load terminations. Mount the contactor with the hardware specified in Figure 2. Loosely

install the (4) mounting bolts into the intended mounting surface. Torque the mounting bolts to 50-75 lb-inches.

2. Connect control wires to the vacuum contactor control terminals A1 and A2 located on the Control-Pak using #18 to #12 gauge 75°C

stranded copper or tin stranded copper wire tightening screw terminals to 7 lb-inches torque.

3. Using 75°C wire copper cable, connect the line and load conductors to the main terminals (Figure 1) and proper phase rotation, tighten the

main terminal bolts to 132 lb-inches torque.

4. Check all connections for accuracy and mechanical connection before energizing.

42052-087

G. Ushakow

N/A

N/A

N/A

42052

1006490

1

INSTRUCTION SHEET

BULLETIN 1102C VACUUM CONTACTOR

CURRENT RATINGS 200A

200V-1500V

2-20-04

Mark Jutz

2-20-04

D. Josef

2-20-04

2

9

REVISION

AUTHORIZATION

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

H

A

B

C

D

E

F

G

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

REFERENCE

SHEET

OF

DWG.

B

DR.

CHKD.

APPD.

DATE

DATE

DATE

±

±

±

ANGLES:

.XXX:

.XX:

THIS DRAWING IS THE PROPERTY OF

THE ALLEN-BRADLEY CO. INC.

AND MAY NOT BE COPIED, USED OR

DISCLOSED FOR ANY PURPOSE EXCEPT

AS AUTHORIZED IN WRITING BY

THE ALLEN-BRADLEY CO. INC.

LOCATION : MILWAUKEE,

WISCONSIN

U.S.A.

SIZE

1

2

3

4

5

6

7

8

E - DOC

ATTENTION: If coil failure is suspected, check that secondary damage has not occurred that will render the contactor non-repairable.

Figure 3A

Figure 3B

Figure 1

Figure 2

(2)

Control-Pak

Cover

Retainer

Contact

Operator

Center

Screws

Lower

Housing

Upper

Housing

Return

Springs

VAC

UUM

CO

NTA

CTO

R

VAC

UUM

CON

TAC

TOR

Coil Replacement Instructions

1. Disconnect all power cables (or bus work) and all control wiring to the contactor.

2. Remove the contactor from its mounted location. The contactor is best serviced in the benchtop position as shown.

3. Remove the cover attachment screws from the contactor and remove the Cover and Retainer (Figure 3A).

4. Disconnect the two wire leads from the Coil to the Control-Pak. Remove the Control-Pak from the contactor and set on benchtop (Figure 3B).

5. Remove the (6) screws that secure the Upper Housing to the Lower Housing by first removing the (4) outer screws and then (2) center

screws. NOTE- Removing the center screws will release the Return Springs. Carefully remove the Upper Housing leaving the Return Springs

in the Lower Housing

(Figure 3B)).

VACUUM CONTACTOR