Grounding, Drive – Rockwell Automation 1329L AC Induction Motors User Manual User Manual

Page 9

AC Induction Motors

9

Procedure:

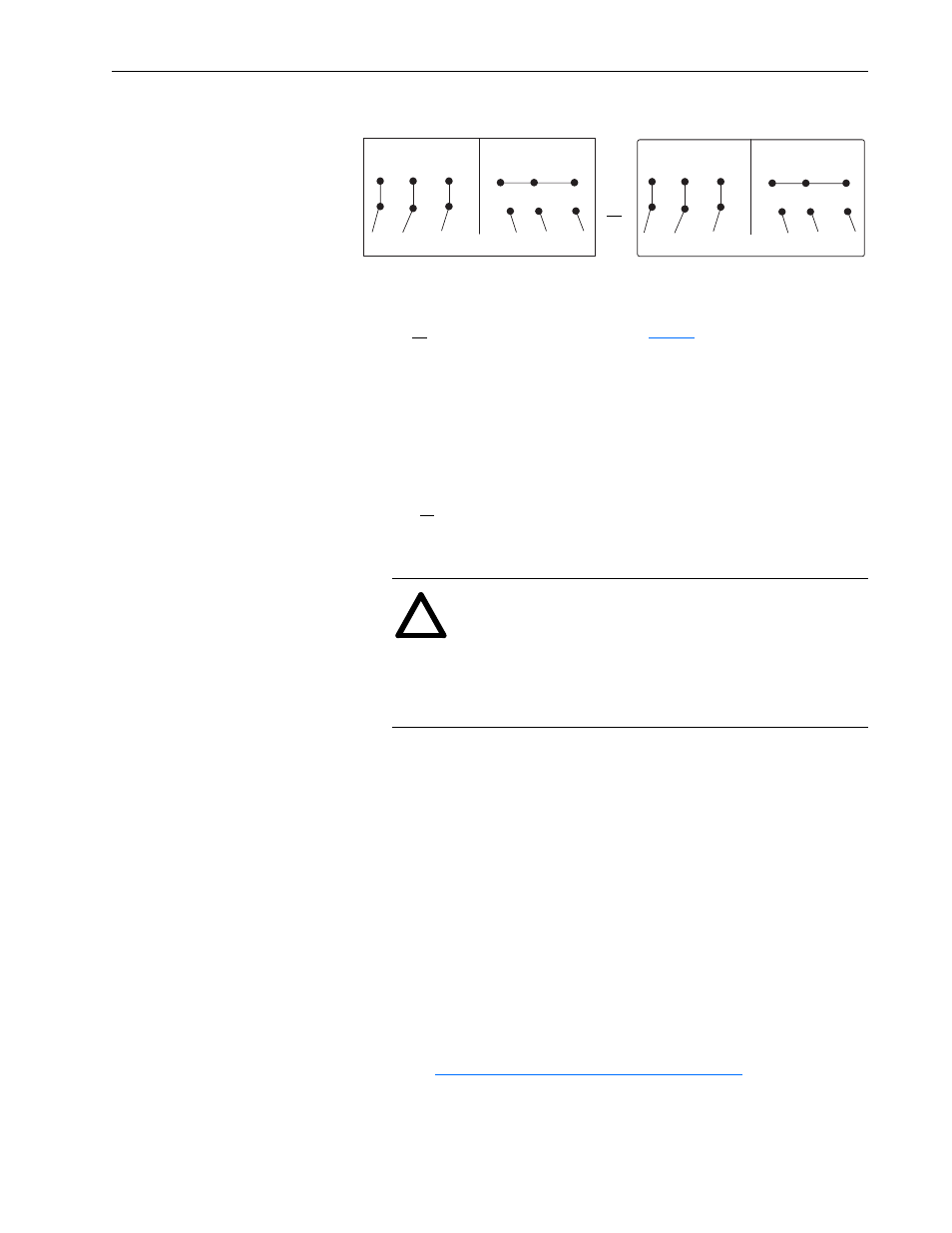

1. Connect for low or high voltage as shown.

2. Check that the direction of air flow is in agreement with the

“direction of air flow” arrows mounted on the motor. If

directional flow is incorrect, interchange power leads to T1 & T2

or U1 & V1.

Grounding

The user is responsible for assuring that the grounding method is in

accordance with the National Electric Code and the applicable local

codes. The ground connection should be a solid and permanent

metallic connection between the ground point, the motor terminal

housing and the motor frame. A ground lead is provided inside the

terminal box.

Due to the need to carry higher frequency ground currents (from

switch voltage waveforms) the ground connection/path must be low

impedance/low resistance. Such ground currents exist during normal

operation on inverter power.

Drive

L180-L320 frame motors are supplied with a shaft suitable for a belt

or coupled drive.

Belt loads should be checked against maximum allowable radial loads

under

“Shaft Loads - Axial and Radial” on page 13

Bradley to determine L440 frame belt load requirements.

Frames L360S and L400S are suitable for coupled duty only, larger

shafts are supplied for belted duty.

(Delta)

(Star)

T6

T4

T5

T6

T4

T5

T1

T2

T3

L1

L2

L3

T1

T2

T3

L1

L2

L3

Low Volts

Line

High Volts

(Delta)

(Star)

W2

U1 = Black

U2 = Green

V1 = Blue

V2 = White

W1 = Brown

W2 = Yellow

U2

V2

W2

U2

V2

U1

V1

W1

L1

L2

L3

U1

V1

W1

L1

L2

L3

Low Volts

Line

High Volts

or

or Connection Diagram shown on

.

!

ATTENTION: Connect an appropriate equipment

grounding conductor to the drive ground terminal, motor

frame, transformer enclosure (if used), drive electrical

enclosure and an appropriate grounding electrode. Failure

to observe these precautions could result in personal injury

and/or death.