Lubrication - frames l180 - l440 – Rockwell Automation 1329L AC Induction Motors User Manual User Manual

Page 17

AC Induction Motors

17

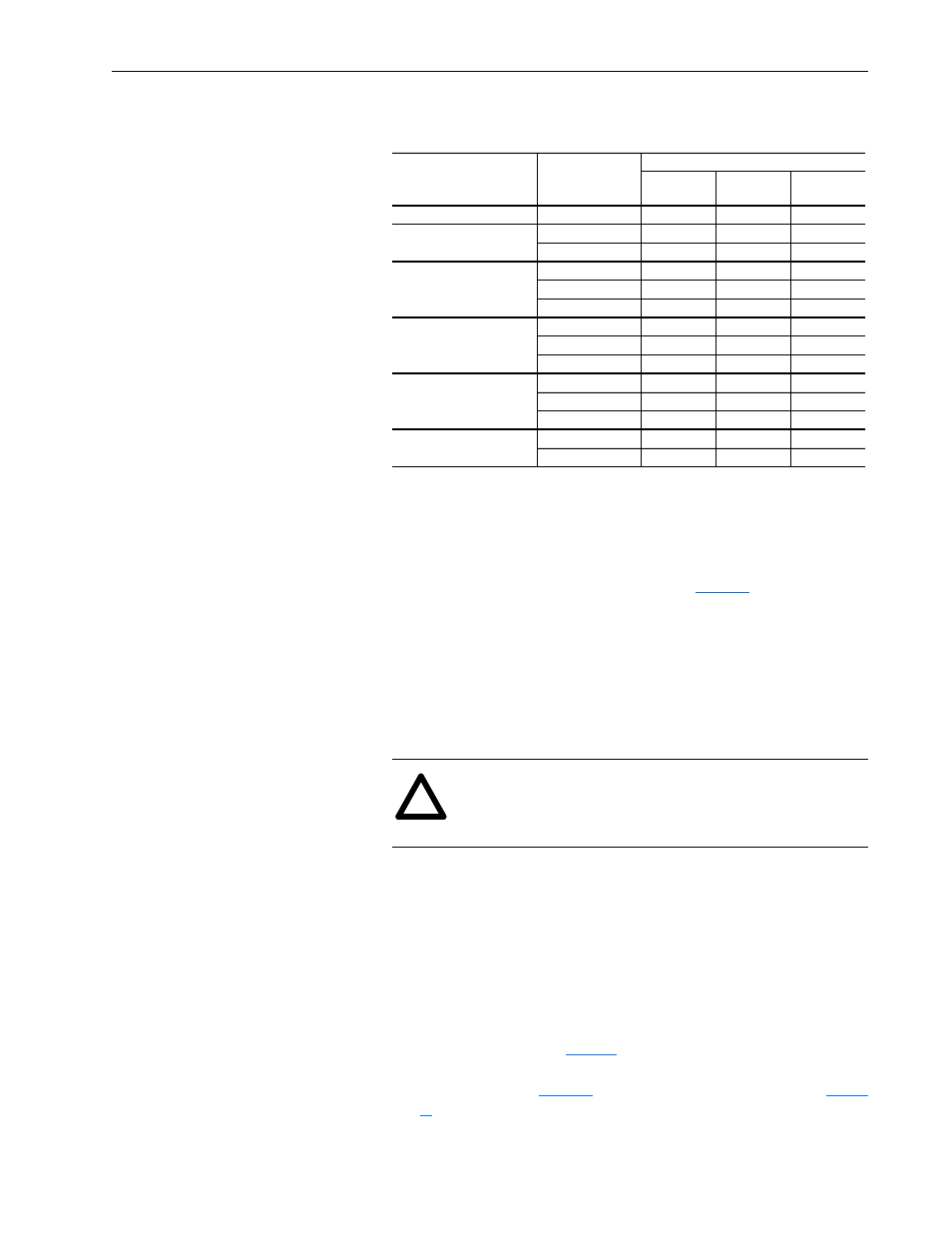

Table H

Relubrication Periods - Frames L180 - L440

1

Maximum speed occupying more than 30% of operating time.

2

For Tandem drives increase frequency of lubrication by multiplying values by 0.8.

Lubrication - Frames L180 - L440

These motors are designed to route new grease directly into the

bearing. The relubrication periods shown in

are offered as a

guide for varying service conditions, speeds, bearing types and

operating hours.

Important: Certain special motors may have a lubrication instruction

plate permanently attached. These specific lubricating

instruction must be followed.

Lubrication Procedure

1. Relubrication with the shaft stationary and a warm motor is

recommended. If lubrication must be done with the motor

running, stay clear of rotating parts and electrical circuits.

2. Locate the grease inlet at the top of the bearing hub, clean the

area and replace the 1/8 inch pipe plug with a grease fitting (if the

motor is not equipped with a grease fitting).

3. Remove grease drain plug located opposite the grease inlet.

4. Using a manual grease gun, pump in the recommended grease in

the amount shown in

. This amount of grease will provide

an ample supply of lubricant between lubrication periods as

determined from

for the service condition listed in

.

Maximum Normal

Operating Speed (RPM)

1

Frame

Relubrication Interval (Months)

Standard

Service

Severe

Service

Extreme

Service

3450 and higher

All

9

4

1

2400 - 3449

L180 - L250

24

9

3

L280 - L440

9

3

1

1700 - 2399

L180 - L320

36

12

3

L360 - L440

18

6

2

UL360 - UL440

9

3

1

800 - 1699

L180 - L320

36

24

8

L360 - L440

36

12

3

UL360 - UL440

9

6

1

500 - 799

L180 - L320

48

36

12

L360 - L440

36

24

8

UL360 - UL440

18

12

4

499 and lower

L180 - L440

48

36

12

UL360 - UL440

24

18

6

!

ATTENTION: If relubrication is done while motor is

running, stay clear of rotating parts. Failure to observe this

precaution could result in personal injury.