Maintenance – Rockwell Automation 1329L AC Induction Motors User Manual User Manual

Page 16

16

AC Induction Motors

Maintenance

Amount of grease to be added to motors is shown in

. See

for relubrication interval. Use Chevron SRI-2 or equivalent

grease unless motor nameplate specifies special grease.

Table F

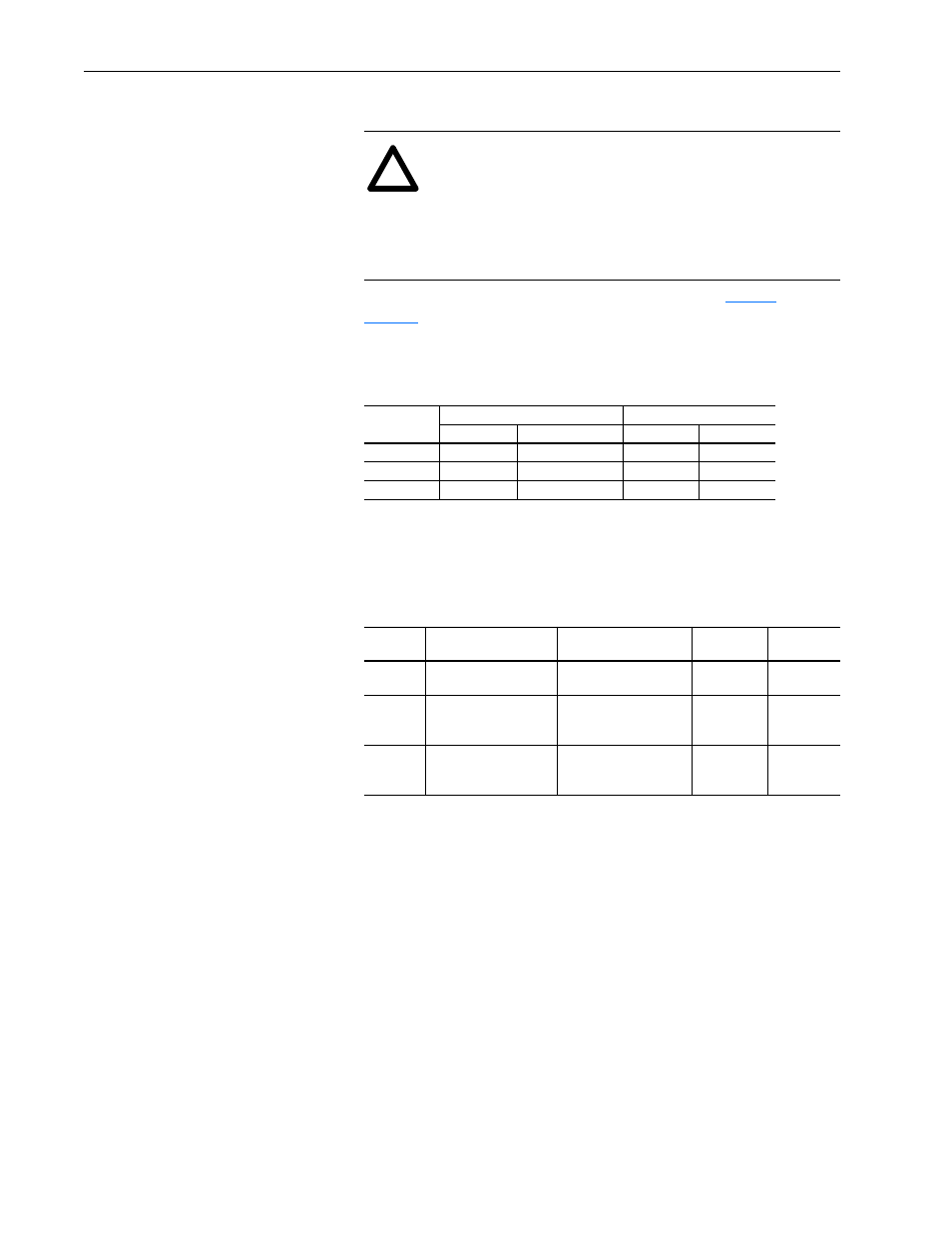

Coupled/Belted or Tandem Duty Grease Amounts

Using the table below, determine service condition on the basis of the

most severe operating parameter (i.e. temperature, bearing load,

atmosphere, or operating hours per day).

Table G

Service Condition

1

Motors must be specially designed for operation in ambient outside the range of –25 to 40 degrees C

(–13 to 104 degrees F). Special grease is required.

2

"EXTREME" service conditions are rare in actual practice. Corresponding lubrication cycles should

therefore be applied with caution. In addition, it is advisable to check with Allen-Bradley for related special

instructions.

!

ATTENTION: Internal parts of this motor may be at line

potential even when it is not rotating. Before performing

any maintenance which could result in contacting any

internal part, be sure to disconnect all power from the motor.

Failure to observe this precaution could result in severe

personal injury or death.

Frame

Volume

Weight

Cubic Inches Cubic Centimeters Ounces

Grams

L180 - L280

1.0

16

0.5

14

L320 - L400

2.0

32

1.0

28

L440

3.0

48

1.5

42

Service

Condition Ambient Temperature

Bearing Load

Atmosphere

Operating

Hours/Day

Standard

–18 to 40 degrees C

(0 to 104 degrees F)

Steady

Clean

8

Severe

–30 to 50 degrees C

(–22 to 122 degrees F)

1

Medium Shock, Vibration

(less than 0.2 in/sec.)

Medium Dirt,

Abrasives,

Corrosion

8 to 24

Extreme

2

–54 to 65 degrees C

(–65 to 149 degrees F)

1

Heavy Shock, Vibration

(more than 0.44 in/sec)

Heavy Dirt,

Abrasives,

Corrosion

8 to 24