Shipping blocks, Encoder connection diagrams – Rockwell Automation 1329L AC Induction Motors User Manual User Manual

Page 10

10

AC Induction Motors

Proper alignment is a key step for long life of bearings, shafts and

belts, and minimum downtime. Misalignment can cause excessive

vibration and damaging forces on shaft and bearings. For direct

coupled drives, flexible couplings facilitate alignment. For belt drives,

the sheave must be placed as close as possible to the motor bracket.

Shipping Blocks

Motors supplied with roller bearings at the drive end are shipped with

wooden blocking to prevent axial movement of the shaft during

shipment. Remove the blocking and bolts securing it and discard.

Make sure motor shafts turn freely. If motor is to be reshipped,

blocking of bearing is required.

Encoder Connection Diagrams

Dynapar H20 – 10 pin M/S Connector

Lakeshore – Epic Connector or Plain Cable

The following table is a universal wiring guide for the latching Epic

connector or plain cable. Wires that are not used should be left not

connected (never connect to power or common). For optimum EMI

noise immunity, connect the encoder shield (pin 10 or braid) to the

cable shield. The encoder shield is internally isolated from the

encoder frame. The cable shield should still be connected to ground at

the receiving end. This encoder has a line driver output. A pull-up

resistor is not required.

!

ATTENTION: Incorrect motor rotation may cause

personal injury or damage the equipment. Check direction

of motor rotation before coupling motor to load.

!

ATTENTION: Ensure that all guards are properly installed

before proceeding. Exercise extreme care to avoid

contacting rotating parts. Failure to observe these

precautions could result in personal injury.

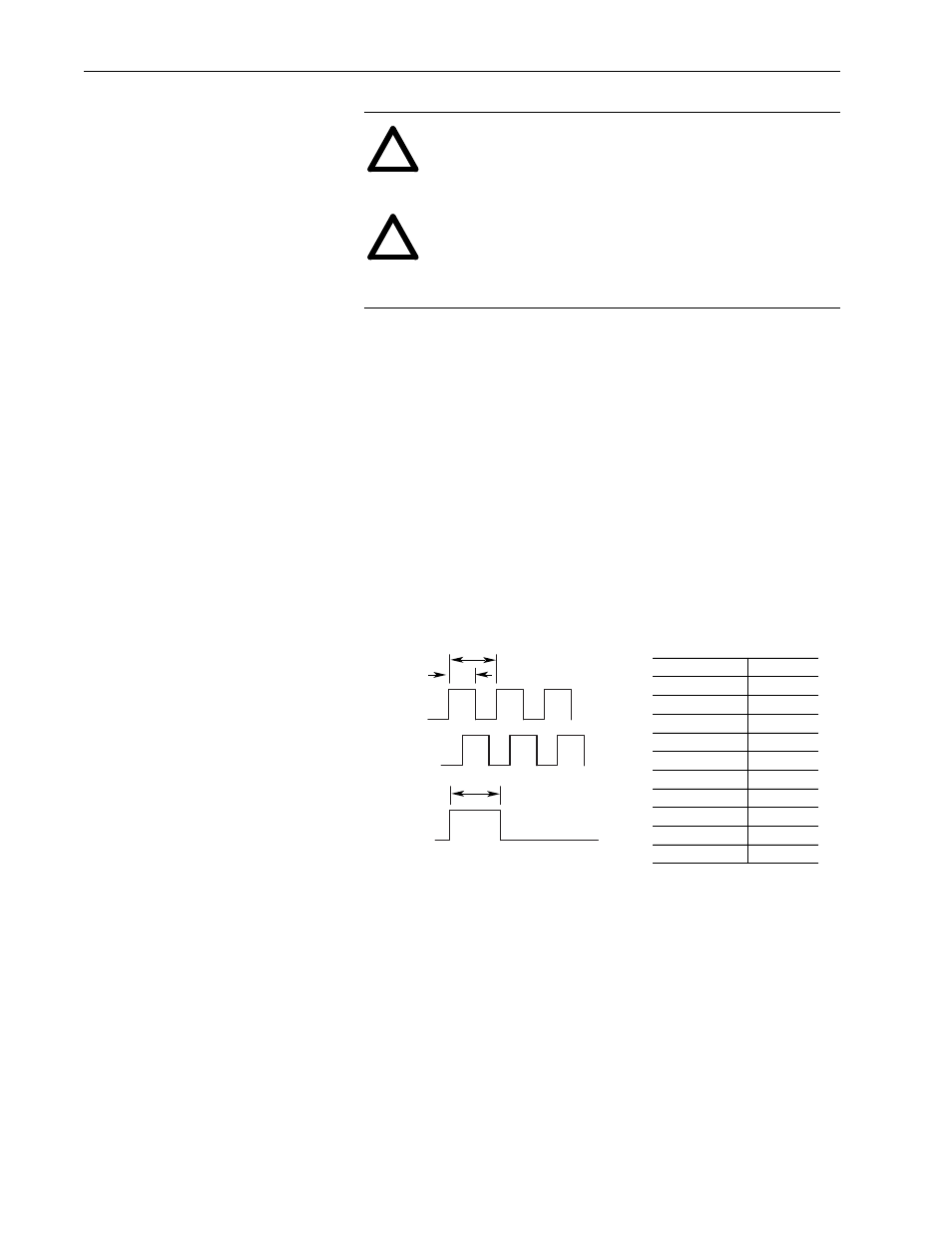

Output A

90

° ±45°

360

°

Output B

Index

Electrical

Output waveform

CCW Rotation of Shaft

360

° ±180°

Output Terminations

Signal

Pin

Output A

A

Output B

B

Output Z

C

Vcc

D

Common

F

Case

G

No Connection

E

Output A (NOT)

H

Output B (NOT)

I

Output Z (NOT)

J