Trouble–shooting, Manual operation – Rockwell Automation 500LG Lighting Contactor Instruction Manual User Manual

Page 15

Installing Bulletin 500LC Lighting Contactors

15

Publication 500LC–IN001A–EN–P May 2005

The Bulletin 500LC Lighting Contactor

is energized. Proceed with care!

CAUTION

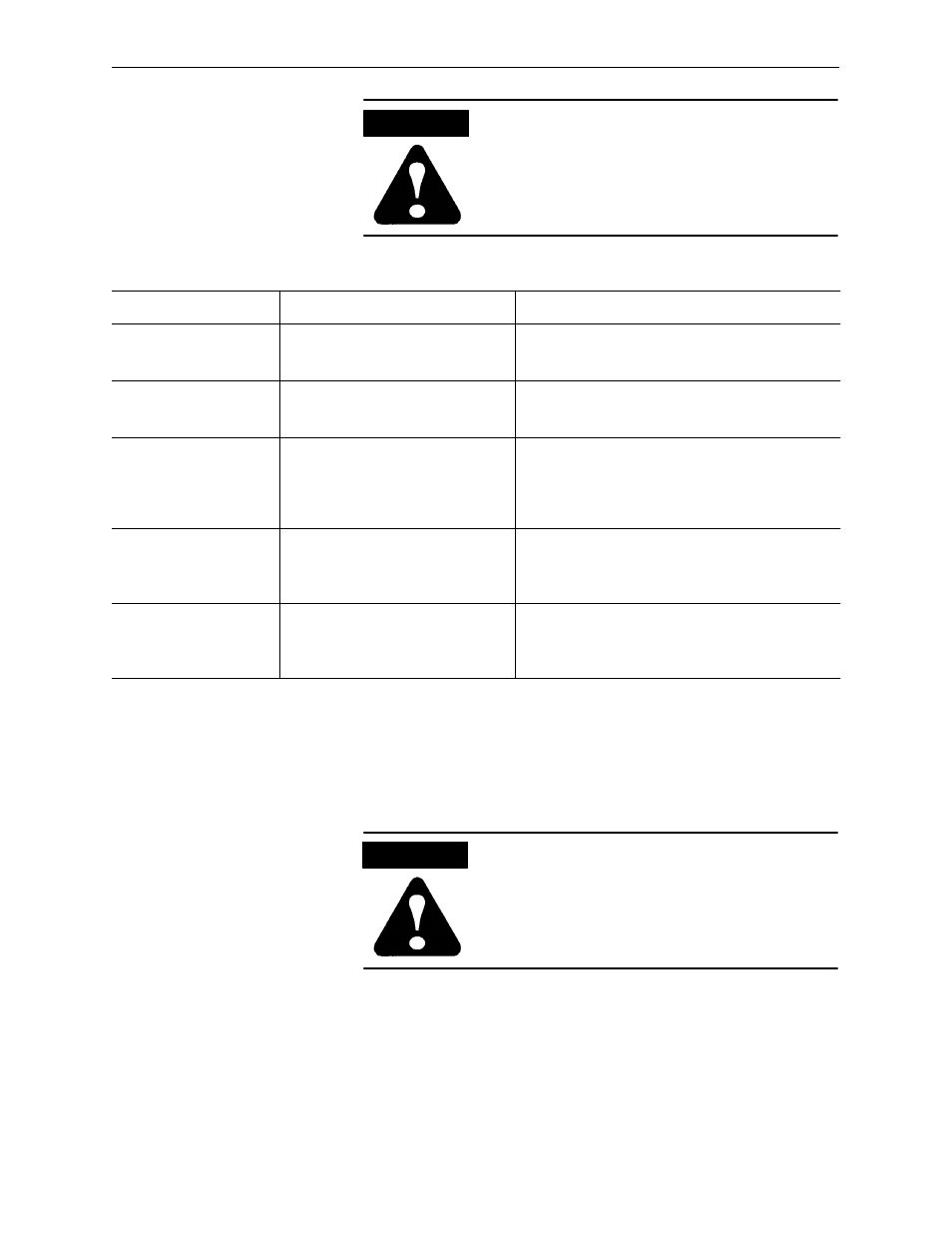

Trouble–Shooting

Problem

Check Control Voltage

Check Control Station, Wiring, Supply

500LC does not

close when control

station is closed.

Measure control voltage

between 500LC terminals

L and C.

If no voltage is present, check control

station contacts, control wiring, supply

fuses, and optional accessories.

500LC does not

open when control

station is closed.

Measure control voltage

between 500LC terminals

L and O.

If no voltage is present, check control

station contacts, control wiring, supply

fuses, and optional accessories.

500LC tries to close

or open, but cannot.

Measure at least 90% control

voltage (nameplate coil

voltage) between 500LC

terminals L and C, or L and O.

If voltage is low, check control wire size

and line run distance; see Table D on page

4. If a transformer is used in the control

line, make sure it can handle the VA

burden required; see Table E on page 4.

500LC closes and

opens repeatedly.

—

Check control station for overlapping

contacts, and correct. Control stations

cannot call on 500LC to close and open at

the same time.

500LC closes or

opens very quickly

with excessive

noise.

Measure no more than 110%

control voltage (nameplate

coil voltage) between 500LC

terminals L and C, or L and O.

If voltage is high, change control supply

or change Bulletin 500LC Lighting

Contactor.

Manual Operation

A #8–32 screw 1–½ in. long can be used to manually operate the

500LC. One is supplied in all replacement parts kits requiring

manual operation. The screw should be used for maintenance

purposes only. Remove the screw after maintenance.

Do not manually operate the

Bulletin 500LC Lighting Contactor

until all power and control circuits

are disconnected.

CAUTION

Open circuit breakers, then use a voltmeter to verify no voltage is

present at the 500LC at both control and line terminal screws.

Insert the operating screw into the center of the coil and carefully

turn it clockwise until the threads engage the cam/core.

Pull the screw outward to open the 500LC contacts; push it in to

close the contacts. Observe the buttons in the contact block

(buttons out means contacts open).