Inspection and service, Inspections, Decommissioning – Rockwell Automation 440R MSR42 Control Module User Manual User Manual

Page 14: Product labels, Technical data, Original instructions

12

Light Curtain Multi-Function Control Module User Manual

Original instructions

Inspection and service

The MSR42 control modules are built electronically and do not need

preventive maintenance.

Inspections

The MSR42 control modules have to be tested periodically – in

accordance with valid regulations - by qualified and trained personnel to

discover prohibited manipulations or unauthorized modifications.

Decommissioning

The MSR42 modules can only be removed, when the machine or the

equipment is shut down completely and can no longer be operated

without tools. If a controller has to be disposed, it can be simply

dismantled. The separated materials can be recycled according to state of

the art technology and corresponding regulations of the country it was

used in.

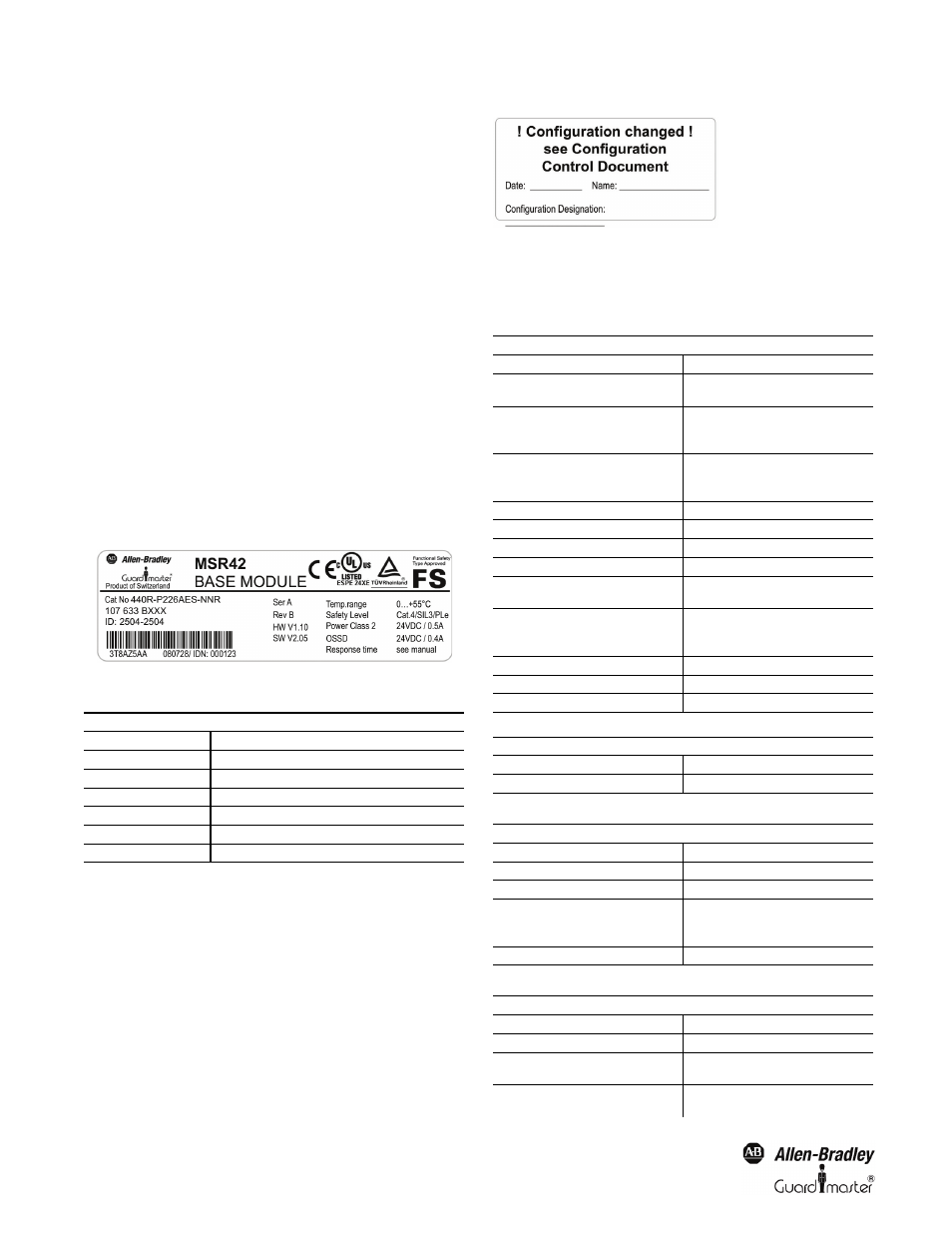

Product labels

All the necessary safety information can be found on the product labels

and the Configuration Control Label, which can be found on each

controller module (example):

Figure 14: Product label MSR42 control module

Table 18

All of the configuration information will also be found on the

configuration control document, which is included with the delivery of

each MSR42 control module.

Note:

In the event that a MSR42 control module is reconfigured by authorized

personnel using the USB/optical interface, a new Configuration Control

Label must be filled out and applied next to the existing label (Figure 15).

Details of the new configuration are given in the configuration control

document.

Figure 15: The new special configuration identification "Configuration changed" must be

positioned next to the existing label.

Technical Data

Explanation of terminology

HW

Hardware Version

Safety Level Cat.

Safety category according to EN ISO 13849-1

Safety Level SIL

Safety integrity level according to EN 61508

Safety Level PL

Performance level acc. to EN ISO 13849-1

Power class

Power supply

Temperature range

Operating temperature range

OSSD

Max. current available per OSSD output, at the listed voltage

General data

Nominal working mode

Continuous process

Temperature range

Environment temp.: 0 ... +55°C

Stock temp.: -25 ... +70°C

Enclosure rating according EN 60529

Housing

Terminals

IP20

IP20

Conductor connection:

4-, 5-pin, terminal strip (plug-in)

Wire cross section:

1 x max 2.5 mm

2

(14 AWG) stranded

spring clamping technology

Quick mounting

Top hat rail 35 mm (EN 50022)

Net weight

130 g (0.287 lbs)

Housing dimensions

111 x 22,5 x 125 mm (incl. plugs) See page 2

Housing material

Polyamide

Vibration according to EN60068-2-6

Amplitude: 0.35 mm

Frequency: 10 … 55 Hz

Shock resistant according to EN 60068-2-29

Acceleration: 100 ms

-2

Impulse length: 16 ms

Number of shocks: 1'000 per direction

Mounting

35 mm DIN Rail

Approvals

TÜV, CE, cULus

Interfaces

Optical (OptiLink)

Weight and packaging

Dispatch packaging

280 mm x 200 mm x 70 mm

Dispatch weight

Net weight + 220 g

Power Supply

Input Power Entry

+24 VDC (EN 60204-1) See page 4

Max. power consumption at max. supply voltage

2.1 W (semiconductor outputs unloaded)

at 5 % residual ripple

0.85 ... 1.15 U

N

Current consumption

Current max. 70 mA + 70 mA per relay extension

module (semi conductor outputs unloaded)

maximal: 1.7 A depending on attached load

Controller protection (external)

5 A slow

Inputs

Safety inputs (software configurable)

(1 x 2 NC or 2x 2 OSSD) and 1 Micro 400

Reset mode

Automatic / Manual or Manual monitored

Control current into:

IN 1, IN 2

2 mA each (min.) (in accordance with EN 61131-2)

Minimum voltage at:

IN 1, IN 2

11 VDC at activated controller (EN 61131-2)