Blanking teach-in, Single scan filter, Testing the msr42 – Rockwell Automation 440R MSR42 Control Module User Manual User Manual

Page 11: Original instructions

9

MSR42 Control Module User Manual

Original instructions

Adjoining of two blanking areas with fixed blanking or floating blanking

with monitoring the resolution in this area rises up for 2 beams. standard

adjoining blanking area

Table 11

Blanking can be activated with

• downloading a customer configuration or

• using the teach-in blanking function.

For configuring blanking and obtaining additional information

surrounding the subject see the description of the software

“Configuration & Diagnostic Tool”.

Blanking Teach-In

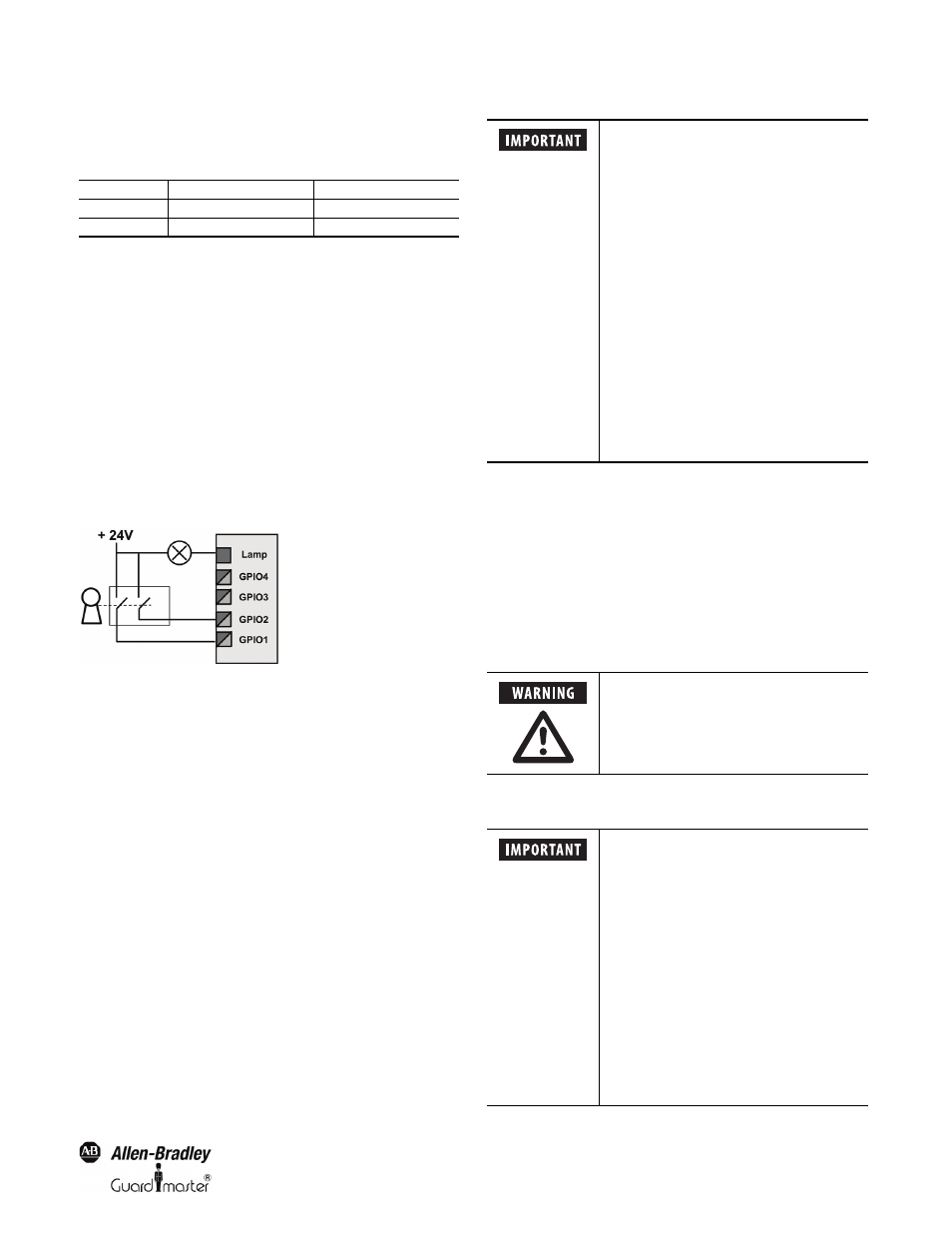

Blanking Teach-in is a function, which allows the ability to set one or two

fixed blanking area(s) without the use of the configuration tool or

configuration software. The customer has to connect a key switch to a

pair of GPIO-inputs according Figure 11. The key switch must have two

channels to select this mode.

Figure 11: Key switch with two channels for activating

When the two channels are closed, the teach-in blanking mode is active

and the lamp is blinking. The safety outputs turn off and the beams

interrupted will be stored as the fixed blanking areas. It is recommended

to teach the MSR42 blanking areas in the application to ensure the

proper beams are blanked. Up to two different fixed blanking zones can

be configured via the external “teach-in” selector switch.

Single Scan Filter

By default the MSR42 is operating in a double scan mode. This mode is

very robust against electrical or optical disturbances. The controller scans

the light curtain optical elements two times to evaluate the state of the

light curtain.

The single Scan Filter can be activated by deselecting the double scan

mode in the Micro 400 window of the MSR42 “Configuration &

Diagnostic Tool” software,

(see “Double Scan Filter” in Software Configuration Tool Manual)

Testing the MSR42

standard

Blanking area

Finger resolution

14mm

34mm

Hand resolution

30mm

80mm

•

Only an authorized person may have

the key to do a teach-in. If the

configuration allows for a teach-in of

fixed blanking the following process

takes place:

•

The blanked object(s) has to be in the

light curtain during the whole teach-

in process.

•

The authorized person has to set the

key switch.

•

After that the teach-in process starts.

The teach-in function is shown when

the connected lamp is blinking. If the

teach-in function is finished and

stored in the MSR42 the lamp will be

on, otherwise the lamp will be off and

the configuration is unchanged.

•

If the teach-in blanking function is

successfully finished the authorized

person has to reset the key switch so

the contacts are open, no longer

connected to 24VDC.

Double scan mode causes a longer

response time than single scan mode.

Consider the relevant maximum response

time when evaluating the safety distance.

The MSR42 control module complies with

safety Category 4, PLe Per EN ISO 13849-1.

The execution of the security function

must be tested at regular intervals via

higher level controllers. The frequency of

this check is based on the results of threat

and risk analysis of the machine (EN ISO

12100-1 and EN14121). Furthermore the

MSR42 control module is certified

according to SIL3 of IEC 61508. Normally

the test input at the main module is

connected to +24 V. If an external test is

desired according to the risk analysis, a

contact can be connected to IN 1. In case

of operation in a “self test mode” both

OSSD outputs have to be connected

separately to the safety circuit of the

machine.