Wolo 410 Wobbler User Manual

Wolo Equipment

INSTALLATION INSTRUCTIONS

For Model 410 Wobbler horn

The addition of a Wolo horn kit in your vehicle will provide an extra level of sound. The Wolo name, with more than

twenty years experience, is your guarantee of a superior horn product. If you need help installing your new Wolo

horn, our technicians are available to answer your questions, Monday thru Friday, from 9 AM to 4 PM EST at

1-888-550-HORN (4676).

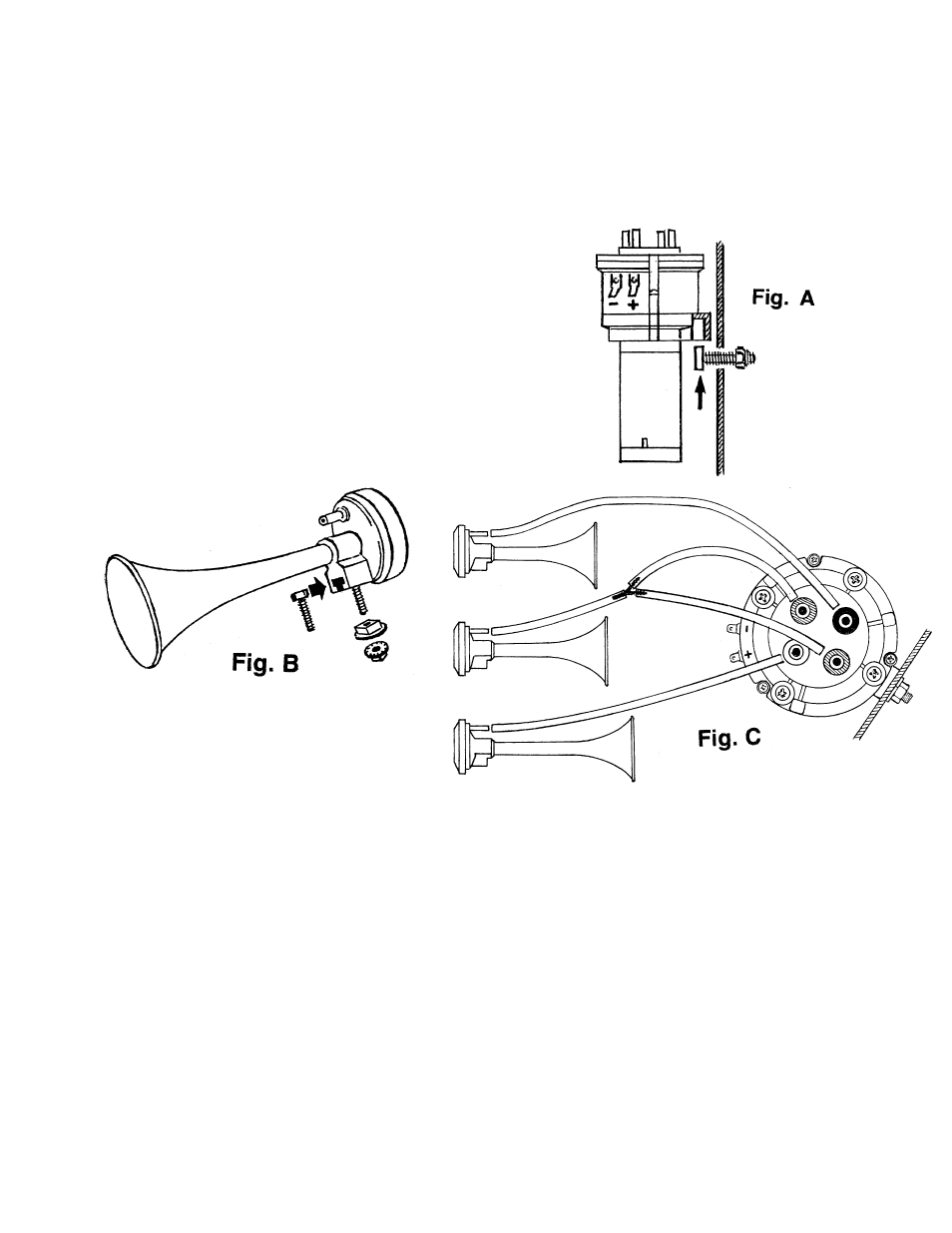

COMPRESSOR MOUTING: FIG. A

1. Install the compressor in the engine compartment in a dry location

and safe from engine and exhaust manifold heat. To secure the

compressor, drill a 3/16-inch hole. Mount compressor vertically (air

outlets at the top). Install the head of the bolt into the slot on the

compressor’s housing and secure to the vehicle using the lock

washer/nut provided.

TRUMPET MOUNTING FIG. B

2. Position each trumpet with open end facing down, mark and drill a

1/4-inch hole for each trumpet. Secure to vehicle using the

mounting hardware in order shown - spacer, lock washer/nut.

3. IMPORTANT: Mount trumpets with the

open ends facing down. This will prevent

water from entering into the trumpets

and compressor. Water damage to the

horn’s component parts is not covered

by our factory warranty.

CONNECTING TUBING FIG. C

4. Using plastic air tubing included in the kit, cut to proper length and install as shown. The inlet fitting on each

trumpet has a colored ring. When connecting the plastic tubing , mate with the same color ring on the compressor

outlet fitting. CAUTION: Avoid making any kinks or sharp bends in tubing that will restrict the airflow and alter the

horn's sound.

ELECTRICAL CONNECTIONS USING VEHICLE’S

FACTORY HORN SWITCH

For a vehicle with a (2) wire system: If vehicle’s factory horn has two (2) terminals, simply transfer the wires to the

terminals on the bottom of the compressor. IMPORTANT: when testing the horns, if compressor motor turns on but

the horn does not sound, reverse the wires connected at the bottom of the compressor.

For a vehicle with a (1) wire system: If vehicle’s factory horn has one (1) terminal, simply transfer wire to the

compressor’s positive (+) terminal on bottom of compressor. The compressor’s negative terminal is connected to

any metal body ground. Connection should be free of rust or paint.