Wolo 619 Big Bad Max User Manual

Big bad max, Fig. a fig. b fig. c fig. d, Installation instructions for model 619

Your purchase of a Big Bad Max Horn is a perfect choice to complement your vehicle. Wolo’s products are manufactured with the finest

materials. Each horn is tested to insure it meets all manufacturing specifications, before it is packaged. If you need help installing this

product, our technicians are available to answer your questions, Monday through Friday from 9 AM to 4 PM EST

by calling 1-888-550-HORN (4676).

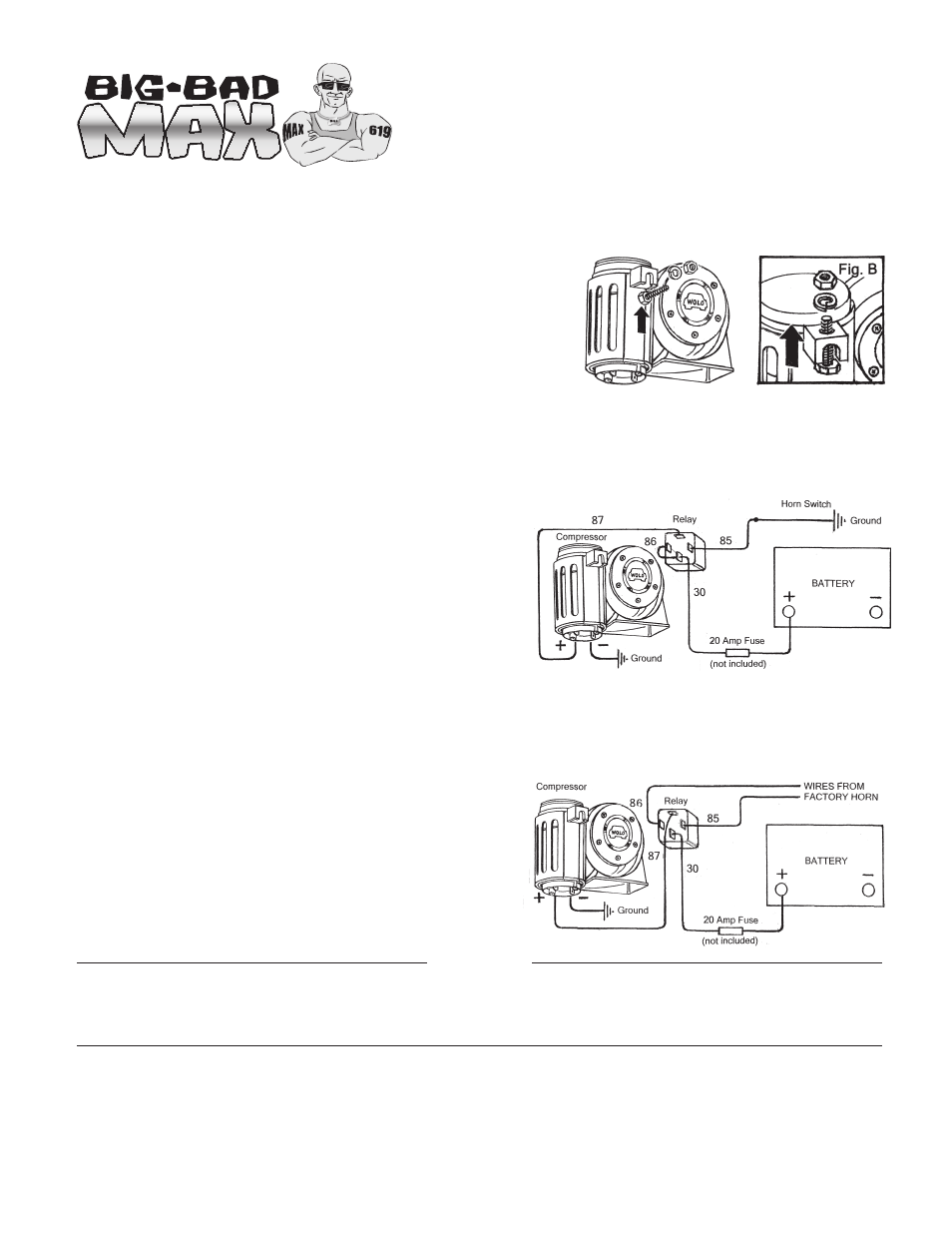

MOUNTING HORN (Choose either method Fig. A or Fig. B):

1. Mount the Big Bad Max Horn vertically when possible in a dry location, safe from

engine exhaust heat and moving parts.

2. Drill a 5/16” hole at the mounting location. Secure horn with method shown in

Fig. A or Fig. B.

3. Fig A: Install the head of the bolt into the slot of the mounting bracket. Secure the

horn using the lock washer/nut provided.

4. Fig B: Install the bolt into the mounting bracket as shown in Fig. B. Secure the horn

using the lock washer/nut provided.

ELECTRICAL CONNECTIONS USING VEHICLE’S FACTORY HORN SWITCH

5. For two (2) wire systems: If vehicle’s factory horn has two (2) terminals, simply transfer the wires to Big Bad Max’s motor terminals.

IMPORTANT: when testing the horn, if the compressor motor turns on but the horn does not sound, reverse the wires.

6. For one (1) wire system: If vehicle’s factory horn has one (1) terminal, simply transfer the wires to Big Bad Max’s (+) motor terminal.

The motor’s (-) terminal is connected to ground, any metal body bolt that is clean of paint and rust. Use 16 gauge wire or heavier.

ELECTRICAL CONNECTIONS FOR USING A NEW HORN BUTTON SWITCH (Fig. C):

7. Install the relay provided in a dry location with the terminals facing

downward near the horn.

8. Connect relay terminal 87 to Big Bad Max’s positive (+) motor terminal.

Use 16 gauge wire or heavier.

9. Connect relay terminal 85 to the horn button switch (not provided). The

other terminal of the horn switch is connected to ground, any metal body

bolt that is clean of paint and rust. Use 18 gauge wire or heavier.

10. Connect relay terminal 30/86 to positive (+) 12-volts such as battery,

alternator, etc. Use 16 gauge wire or heavier. Protect the electrical circuit

with a twenty (20)-amp fuse (not included).

RECAP OF RELAY TERMINAL CONNECTIONS

• Terminals 30/86: the two terminals are connected to 12-volts positive (+) using a

fuse. • Terminal 85: is connected to horn switch. • Terminal 87; is connected to the horns (+) motor terminal

Installation Instructions for Model 619

BIG BAD MAX

™

© 2012 Wolo Mfg. Corp All Rights Reserved.

Patent: US D611,864, US Pat. 7,978,078,

US 7,802,535, US 7,712,430 EP DSN NO. 001129159-0001, CN Pat.ZL200930182277.0

Other patents pending All Rights Reserved

MOTORCYCLE

ELECTRICAL CONNECTION – USING FACTORY HORN SYSTEM (TWO WIRE SYSTEM) Fig. D

1. IMPORTANT: You are required to use the relay supplied with this horn kit to protect the factory horn button switch and wiring. The

original factory horn draws less amperage so most motorcycle manufacturers do not provide a relay in the horn circuit.

2. Remove the two (2) wires from the factory horn.

3. Connect relay terminal 85 to one of the factory horn wires. Note: It does

not make a difference which wire.

4. Connect relay terminal 86 to the other factory horn wire.

5. Connect relay terminal 30 to positive (+) 12-volts battery, alternator. Use

16-gauge or heavier wire. A 20-amp fuse should be used as shown in

Fig. D to protect the motorcycle.

6. Connect relay terminal 87 to the positive terminal at the bottom of the

compressor. Use no less than 16 gauge wire.

7. Connect the (-) terminal at the bottom of the compressor to ground any

clean metal body bolt or the (-) post of the battery. Use no less than 16-gauge wire.

WARRANTY

W

olo Manufacturing Corporation (“Wolo”) warranties to the original purchaser, for three months from the date of purchase, that this product is free from

defects in workmanship and materials. If there is such a proven defect, Wolo, at its option, will either repair or replace the item free of charge, if it is returned

to Wolo within three months from the date of purchase together with proof of purchase as described below. Wolo reserves the right to inspect any defect

prior to settling any warranty claim by repair or replacement. This warranty is limited as above provided and Wolo will not be responsible for fire or other

casualty or accident, due to neglect, abuse, abnormal use, modifications, faulty installation of this product, or natural causes.

ANY EXPRESSED WARRANTY NOT PROVIDED HEREIN IS EXCLUDED AND DISCLAIMED. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

OF FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY LIMITED TO A TERM OF THREE (3) MONTHS. UNDER NO CIRCUMSTANCES SHALL

WOLO BE LIABLE TO PURCHASER OR ANY OTHER PERSON FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES, WHETHER ARISING OUT OF

BREACH OF WARRANTY OR OTHERWISE.

To obtain warranty service, return the product prepaid, and include the original bill of sale showing the date of purchase. Provide with the return a

brief description of the problem. Also, include with the return a check or money order in the amount of $10.00 to cover return shipping. Mail to:

Wolo Manufacturing Corp. • One Saxwood Street, Deer Park, NY 11729 Attn: Warranty Service E-mail: [email protected]

Fig. A

Fig. B

Fig. C

Fig. D

™

™