Wolo 415-24 Airsplitter User Manual

Instal l ation instructions, Mode l s

INSTAL

L

ATION INSTRUCTIONS

for

Mode

l

s

400-24, 402

-

24, 403-24, 404-24, 405-24

,

415-24

&

41

7

-

24

The

c

R

l'b

rdonof a Wolo horn kit for your vehicle wil

l

provide an extra level of sound

.

The Wolo name

,

with more than

twenty

y

ears e

x

perience, is your guarantee of a superior horn product

.

If you need help

i

nstall

i

ng you

r

ne

w

Wolo horns

,

ou

r t

e

chni-

ci

ans are available to answer your questions, Monday through Friday from 9 AM to 4 PM EST

.

BBB

-

550-Horn (46

7

6)

.

1. I

ns

t

a

l

l the compressor

i

n

t

he eng

i

ne

c

ompar

t-

ment

i

n a dry location and safe from engine and

e

x

haust mani

f

old

hea

t

.

2

.

To secure the compressor

drill one 3/16

i

n

.

hole.

Mount the compresso

r

v

e

rtically

(air outlet on

t

op)

.

Install the head of the bolt into the slot on

t

he compressor

housing.

Secure the compres

-

so

r

to the vehicle using the lock washer/nut

pro-

v

ided

.

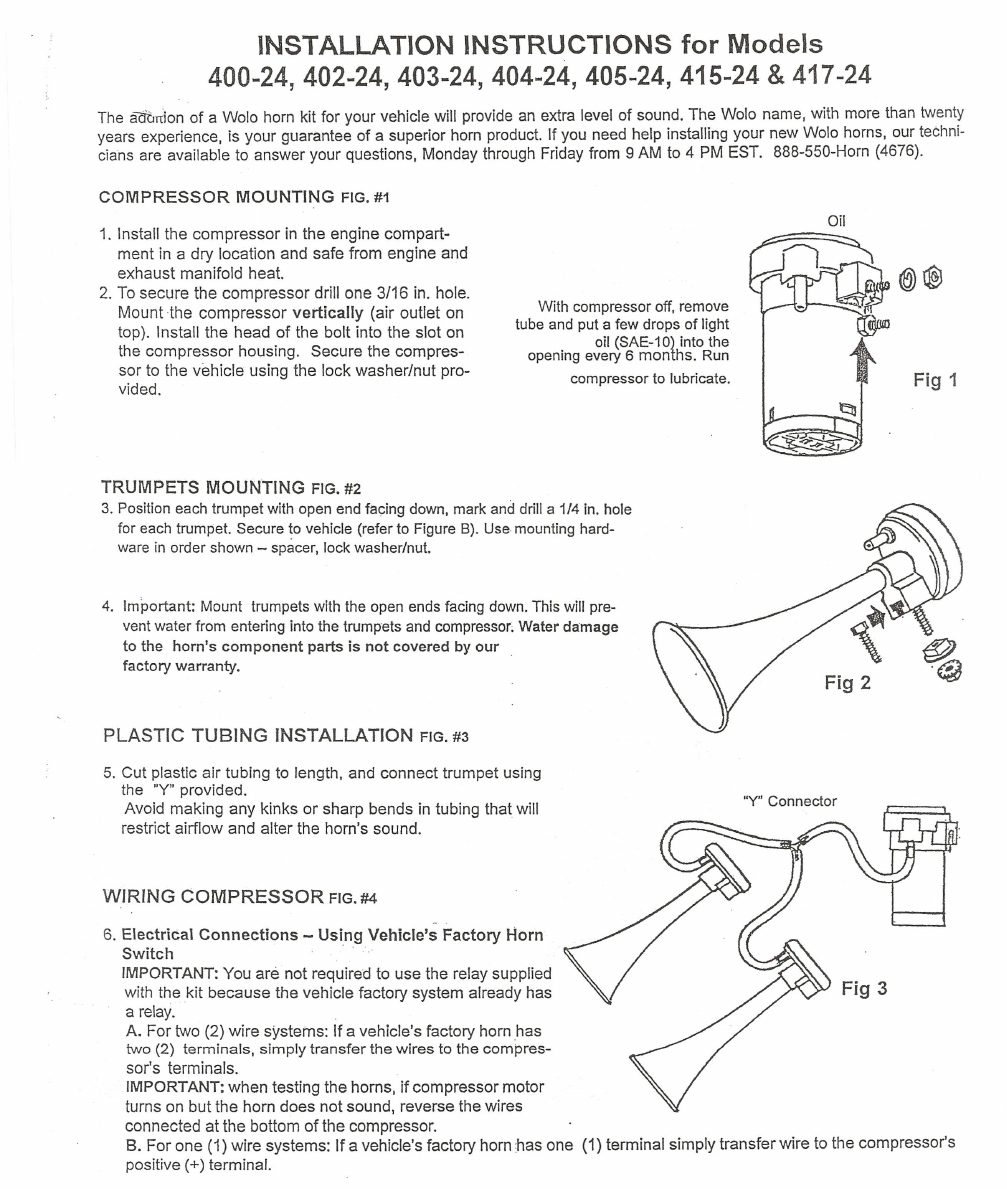

With comp

r

essor o

f

f

, r

emove

tube and pu

t

a

f

e

w

drops of l

i

ght

oil (SAE-10) into the

open

i

ng every 6 mon

t

hs

.

Run

compressor

t

o lubrica

t

e

.

TRUMPETS

MOUNTING

FIG. #2

3

.

Posi

ti

on each

t

rumpe

t w

ith open en

d

facing down

,

mark and dri

l

l

a

1/4 i

n

.

hole

f

or

e

ac

h t

rumpe

t

.

Secure

t

o vehicle (

r

efer

t

o F

i

gu

r

e

B)

.

Use moun

t

ing hard

-

wa

re in orde

r

sho

w

n

-

spacer

,

lock washer/nut

.

4. I

mpor

t

an

t: M

oun

t t

r

u

mpe

t

s

wit

h

t

he open ends

f

ac

i

ng do

w

n

.

Thi

s

will pre

-

vent w

ater f

r

om ente

r

ing in

t

o

t

h

e tr

umpets and comp

r

essor

; Wat

e

r d

a

m

a

ge

t

o

t

he

h

o

rn'

s

c

o

mponent

pa

r

t

s

i

s

n

o

t c

ov

er

e

d

by

our

f

ac

t

o

r

y wa

rran

ty

.

5

.

Cu

t

plastic ai

r t

ub

i

n

g t

o

l

e

n

gth

,

and connect tru

m

pe

t

us

i

ng

the

"

Y

"

provide

d

.

Avoi

d

mak

i

ng an

y

ki

n

ks o

r

sharp bends

i

n tubing

t

hat

w

ill

r

estr

i

ct a

i

rf

l

ow and al

t

er

t

he

h

orn'

s

sound.

6. Ele

c

tri

ca

l

Conn

e

cti

o

ns

- Using Vehicle's

Factory

H

orn

Swit

c

h

.

.

.

IMP

O

RTANT: Y

ou are no

t r

eqUired

t

o

u

se

t

he

r

elay s

u

pplied

w

i

t

h

t

he

ki

t because the vehicle fac

t

ory system a

l

ready has

a rela

y

.

A

.

For t

w

o (2) wire s

y

s

t

ems

:

I

f

a vehicle

'

s

f

acto

r

y ho

r

n has

t

w

o (

2

) term

i

nals

,

s

i

mply

t

ransfer t

h

e

w

ires

t

o the com

p

res

-

sor's terminals.

IM

POR

TANT:

when

t

est

i

ng

t

he ho

rn

s

,

i

f

co

m

pressor

moto

r

t

urns on but the horn does no

t

sound

, r

everse

t

he wires

connected

at the bo

t

tom o

f

the compressor.

B

.

For one (1) w

i

re systems

:

I

f

a vehicle

'

s fac

t

ory horn

:

has one (1) te

r

minal simply transfe

r

wire to

t

he compresso

r's

pos

i

tive

(+)

term

i

nal

.