Wolo 849 Siberian Express User Manual

Lanyard valve and hose installation (fig. b), Horn installation (fig. a)

INSTALLATION INSTRUCTIONS

For Models 839, 849 & 852 Train Horns

Your purchase of a Wolo Train Horn is the choice to compliment your vehicle. Wolo’s products are manufactured with the

finest materials. Each horn is tested to insure it meets all manufacturing specifications, before it is packaged. If you need

help installing your new Wolo horn, our technicians are available to answer your questions, Monday thru Friday, 9 AM to

4 PM EST at 1-888-550-HORN (4676).

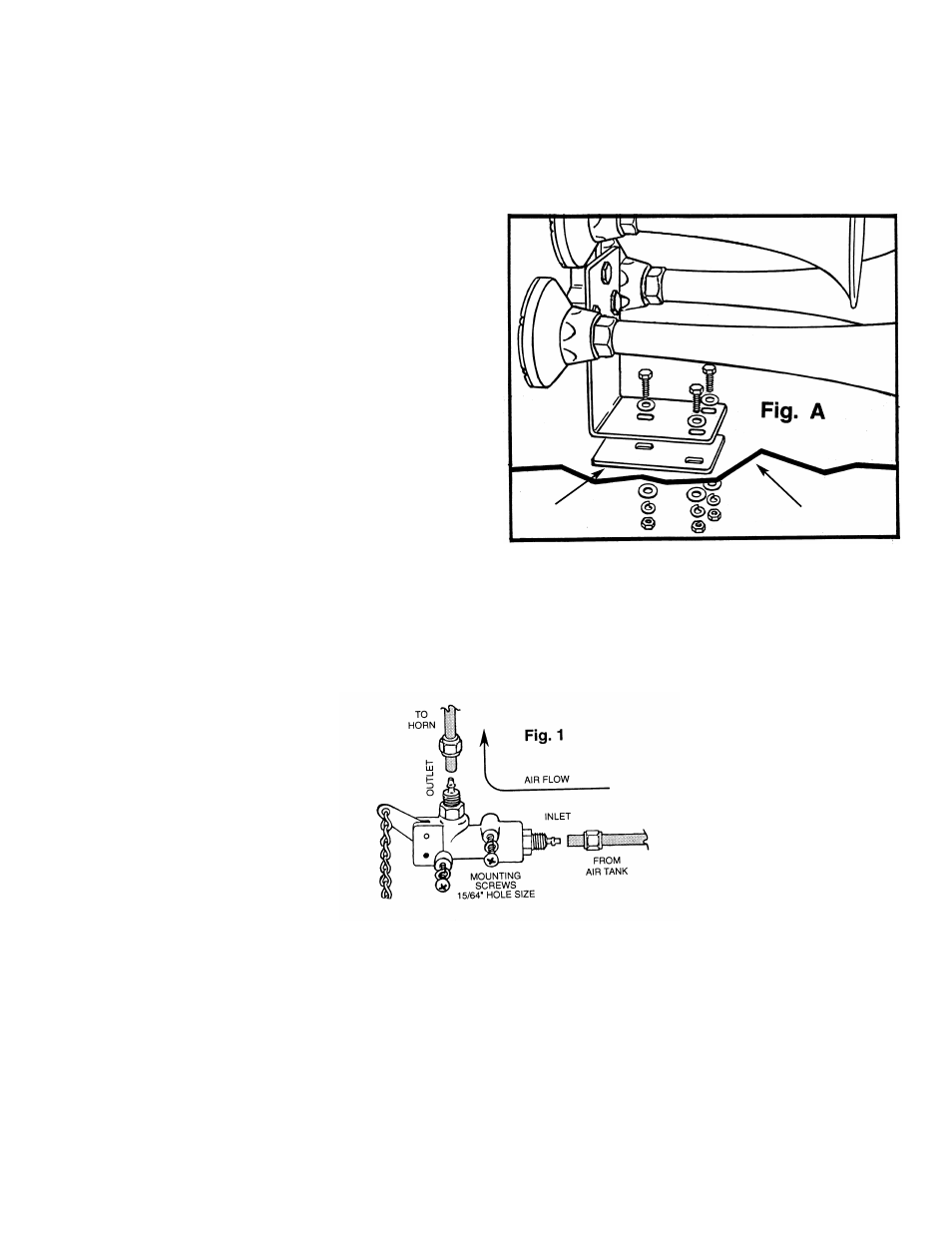

HORN INSTALLATION (Fig. A)

1. Locate a mounting location that is a solid metal surface

such as the vehicle’s frame or chassis to help prevent

excessive vibration, which could damage the horn.

IMPORTANT: Do not mount horn on a plastic fender well

or on flexible material. For best results, the front of the

horn should be unobstructed so that the sound can carry

straight ahead.

2. Use the base of the horn as a template, mark the hole

locations and drill to size 5/16".

3. Place the gasket between the mounting surface and the

base of the horn.

4. Secure the horn with the hardware provided and tighten

evenly.

LANYARD VALVE and HOSE INSTALLATION (Fig. B)

5. Mount the lanyard valve in a convenient location so that its chain can be easily reached by the driver. Using the

lanyard valve as a template, drill holes and mount with screws provided.

6. Using the 1/4” plastic hose provided, cut to size so to connect the vehicle’s air tank to the inlet fitting of the lanyard

valve. Place the brass nut and compression fitting onto the hose. Push the hose into the female fitting of the lanyard

valve and tighten the brass nut. CAUTION: Do not over tighten the brass nut.

7. Using the 1/4” plastic hose provided, cut to size so to connect the lanyard valve to the inlet fitting of the horn. Place

the brass nut onto the hose. Push the hose on to the male fitting of the lanyard valve and tighten the brass nut.

CAUTION: Do not over tighten the brass nut.

8. Place the brass nut, then the compression fitting onto the other end of the air hose. Push the tube onto the horns

male inlet fitting. Thread the nut onto the fitting and tighten. CAUTION: Do not over tighten the brass nut.

IMPORTANT: NEVER INSTALL THE HORN TO AN AIR TANK THAT CONTROLS THE AIR BRAKES OR ANY

OTHER CRITICAL OPERATING SYSTEM.

MOUNTING SURFACE

RUBBER GASKET