Wolo EE100 Electronic Industrial Horn User Manual

Wolo Equipment

INSTALLATION INSTRUCTIONS

FOR MODEL EE100 ELECTRONIC INDUSTIAL HORN 12 – 60 Volt DC

Your purchase of a Wolo industrial horn is a perfect choice for your equipment for both new and replacement

requirements. Wolo’s products are manufactured with the finest materials. Each horn is tested to ensure it meets all

manufacturing specifications, before it is packaged. If you need help installing this product, our technicians are available

to answer your questions, Monday through Friday from 9AM to 4 PM EST by calling 1-888-550-HORN (4676).

IMPORTANT: The EE100 has an operating voltage range of 12-60 VDC; before installing this horn make sure the

voltage rating matches the vehicles operating voltage and or horn system’s voltage. The EE100 will automatically sense

and adjust to any operating voltage within the range of 12-60 VDC. There is no adjustment or setting that the installer

has to make.

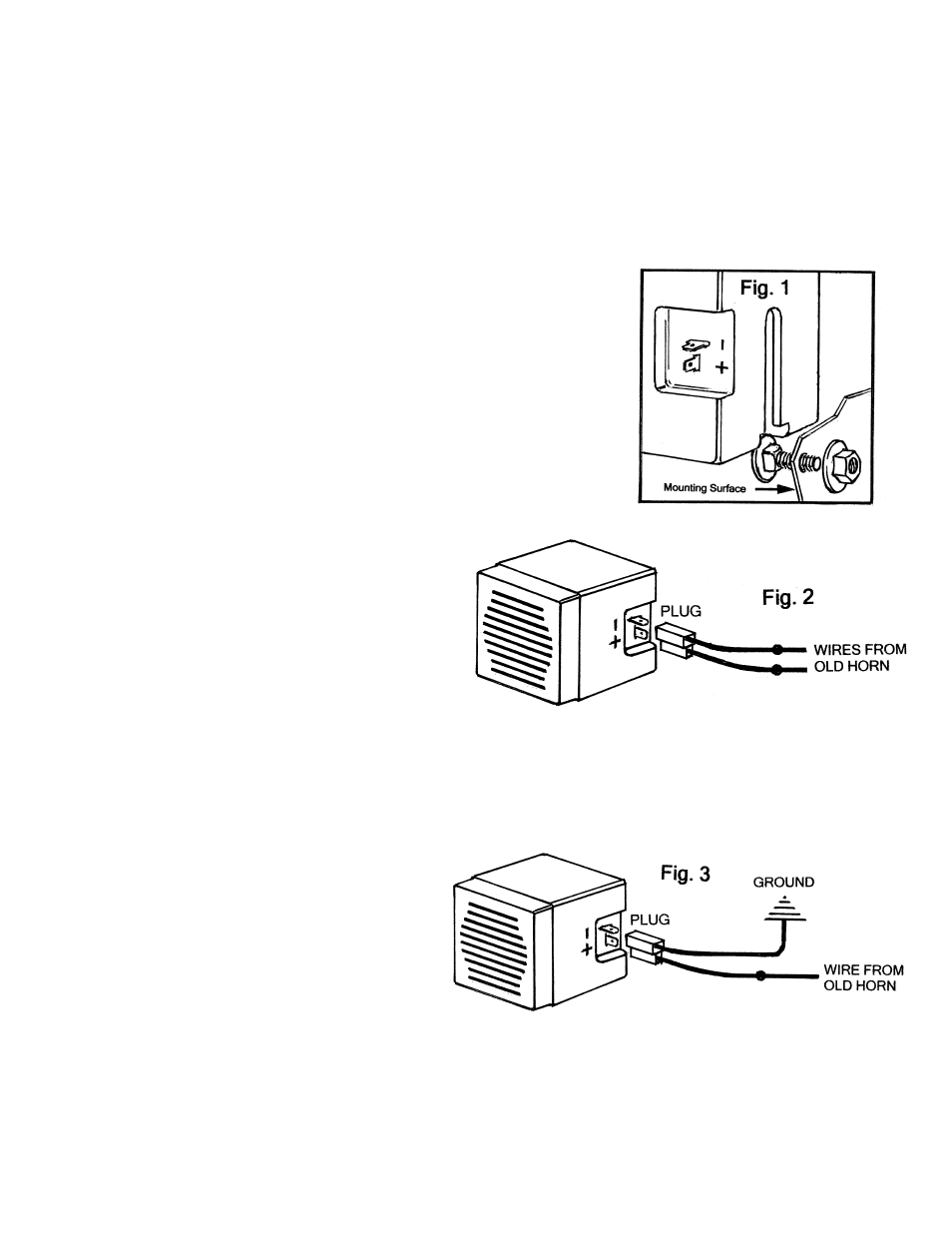

MOUNTING FIG. #1

1. Remove the factory horn, and install the EE100 in the same location. When

possible face the horn downward to prevent dirt and water from entering into the

horn. To secure the EE100 to the selected location drill a 5/8” hole. Place the bolt

that is provided into the drilled hole and thread the nut/lock washer onto the bolt,

two to three turns. Slide the horn onto the head of the bolt using the slotted track

on the side of the EE100. Secure the horn to the vehicle by tightening the nut/lock

washer.

WIRING

TWO (2) TERMINAL WIRING FIG. #2

(Replacement Installation, for vehicles that have an existing horn system)

2. For vehicles where the factory horn wires are connected

to two (2) horn terminals, simply transfer the factory horn

wires to the power plug provided with the EE100, follow

steps 3-6 below.

3. The RED WIRE of the power plug provided is connected

to the vehicle’s horn wire that is (+) positive.

4. The BLACK WIRE of the power plug provided is

connected to the vehicle’s horn wire that is (-) negative.

5. Carefully inspect the horn wires before connecting them to the power plug so to ensure that they are clean and free of

dirt and corrosion. IMPORTANT: Always make sure that a 3-amp inline fuse is used in the horn circuit to protect the

vehicle, (fuse not included). Make sure all connections are taped and secured.

6. Connect the plug to the EE100. The horn installation is complete and the horn is ready to be used.

ONE (1) TERMINAL WIRING FIG. #3

(Replacement Installation, for vehicles that have an

existing horn system)

7. For vehicles where the factory horn wire is connected

to one (1) horn terminal, simply transfer the factory

horn wire to the power plug provided with the EE100,

follow steps 7-10 below.

8. The RED WIRE of the power plug provided is

connected to the vehicle’s horn wire that is (+) positive.

9. The BLACK WIRE of the power plug provided is connected to ground, (-) negative, using any of the following

locations: under any clean metal body bolt or the negative post of the battery. Always make sure the metal ground

surface is free of paint, rust and oxidation.

10. Carefully inspect the horn wire before connecting it to the power plug so to ensure that they are clean and free of dirt

and corrosion. IMPORTANT: Always make sure that a 3-amp in-line fuse is used in the horn circuit to protect the

vehicle, (fuse not included). Make sure all connections are taped and secured.