Wolo 836 Silver Streak User Manual

For silver streak dd – model 836, Installation instructions, Wiring

AIR HORN INSTALLATION

1. Locate the desired area you wish to mount the dual

trumpet air horn. For best results, the front of the horn

should be unobstructed so that the sound can carry

straight ahead.

2. Unscrew one of the trumpets and unscrew and remove the

chrome air tank between the trumpets for access to the

horn’s mounting bracket.

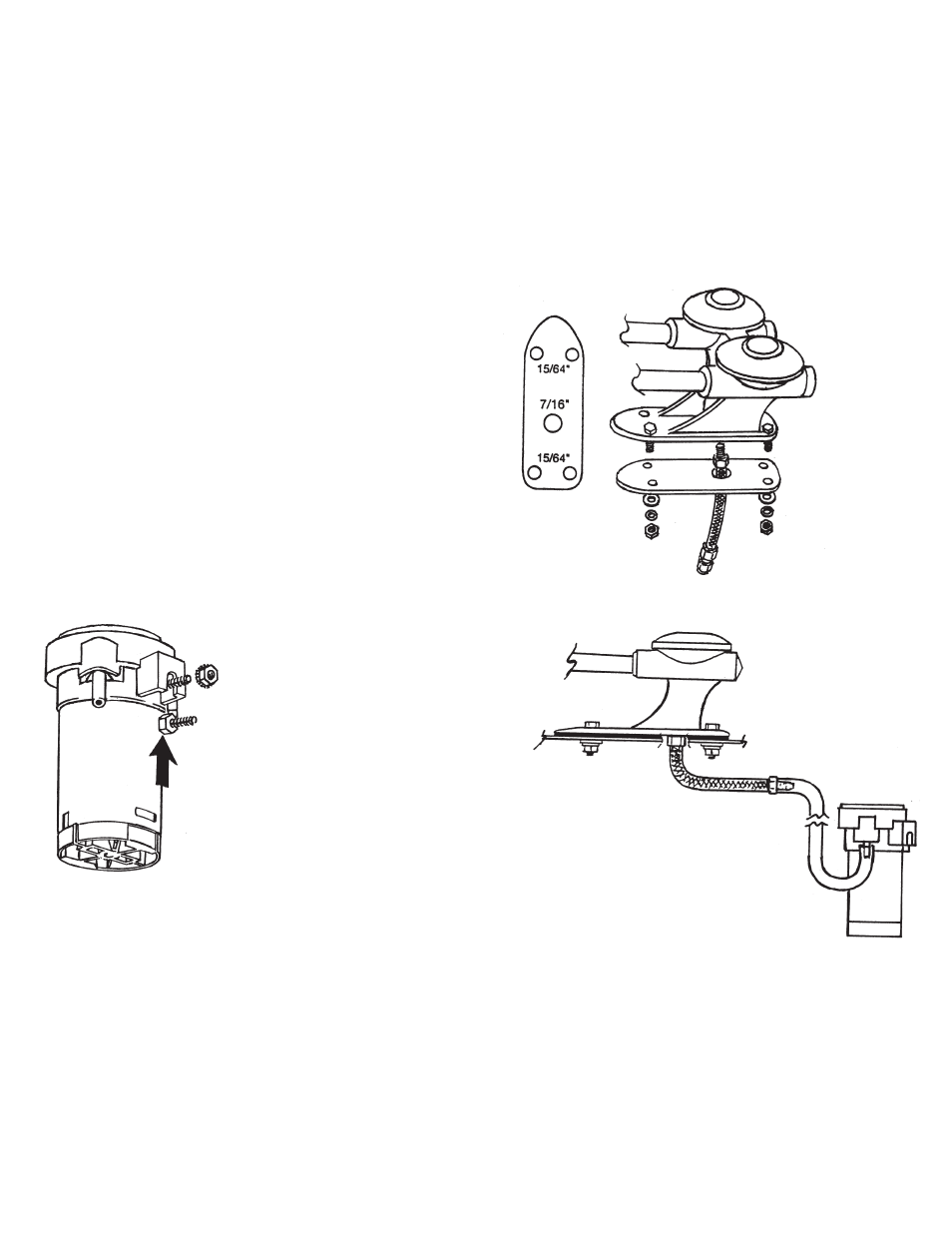

3. Use the horn’s rubber gasket as a template. Mark hole

locations and drill to size as shown in Fig. A.

4. Secure the horn with hardware provided. Tighten evenly to

provide a good water tight seal. Fig. A.

5. Secure the flexible inlet hose into the base of the horn. Do

not remove the Teflon tape on threaded end of hose. The

tape is used to prevent air leaks.

6. Install the tank and the trumpets back onto the horn‘s base.

Only hand tightening is necessary.

COMPRESSOR INSTALLATION

7. Install the compressor in a dry location.

IMPORTANT: Compressor must be

mounted not further than 8 to 10

inches from the trumpet for proper

sound.

8. To secure the compressor drill one

5/16” hole. When possible, mount the

compressor (air outlet on top). Install

the head of the bolt into the slot on the

side of the compressor. Secure the

compressor to the vehicle using the

lock washer/nut provided as shown in

Fig. B.

9. Using the plastic tubing provided,

connect the compressor to the horn’s

flexible inlet hose as shown in Fig. C.

Caution: Avoid making any kinks or

sharp bends in plastic tubing that will

reduce air flow and alter the horn’s sound.

WIRING

10. Electrical Connection – Using Vehicle Factory Wiring

IMPORTANT: You are not required to use the relay supplied with the kit because the vehicle factory system already

has a relay.

A. For two (2) wire systems: If vehicle’s factory horn has two (2) terminals, simply transfer wires to the compressor’s

terminals. IMPORTANT: when testing the horn if compressor turns on but the horn does not sound, reverse the

wires connected to the compressor.

B. For one (1) wire systems: If vehicle’s factory horn has one (1) terminal, simply transfer the wire to the compressor’s

positive (+) terminal.

C. Using wire provided or heavier 16-gauge, the compressor’s negative terminal is connected to any metal body bolt. A

ground connection should be free of rust and paint.

INSTALLATION INSTRUCTIONS

for Silver Streak DD – Model 836

The addition of a Wolo horn for your vehicle will provide an extra level of sound. The Wolo name, with more than twenty

years of experience is your guarantee of a superior horn product. Each horn and compressor is bench tested before it is

packaged. Precision workmanship and quality components will assure years of reliable service. If you require assistance

installing your new Wolo horn, our technicians are available to answer your questions, Monday through Friday from 8 AM to

4 PM EST 1-888-550-HORN (4676).

Fig. A

Fig. B

Fig. C