Compressor installation, Weather protection covers – Wolo 418 Powerhouse User Manual

Page 2

COMPRESSOR INSTALLATION

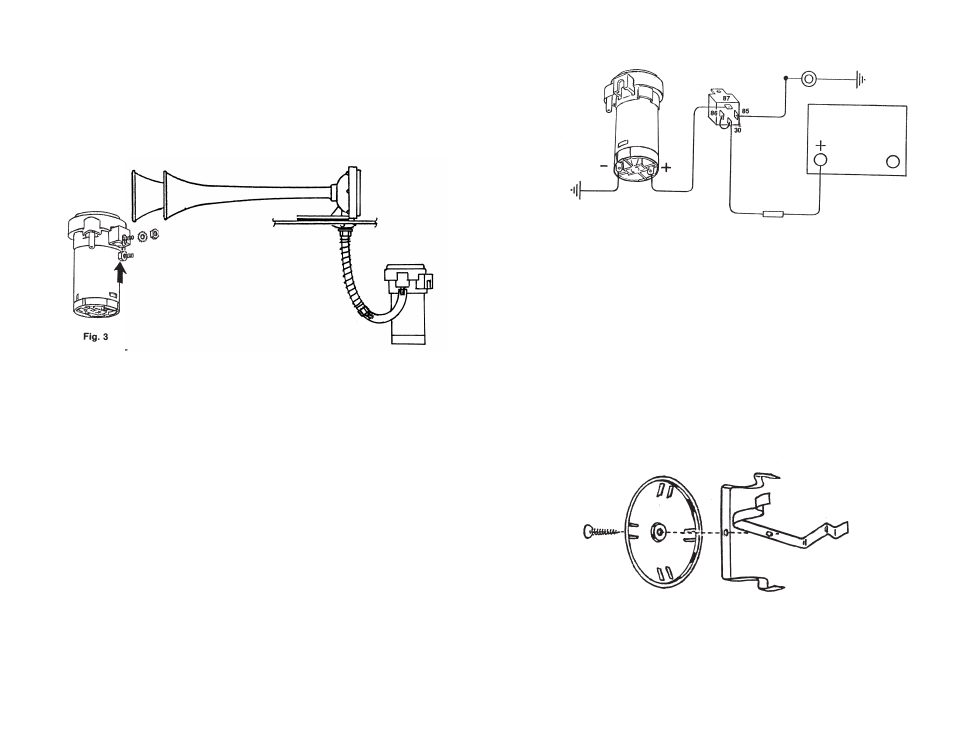

4. For best performance mount the compressor close to the trumpets. The compressor is not

water resistant, it is important that it be mounted inside the vehicle in an area that is dry.

5. The compressor should be mounted vertically, with its air outlet facing down.

6. Drill a 5/16 inch mounting hole. Using the hardware shown in Fig. 3, secure compressor.

CAUTION: Plastic tubing between compressor and trumpets should not have sharp bends or

kinks which might stop or reduce air flow, resulting in reduced sound output. Fig. 4.

7. Electrical Connections – Using Vehicle’s Factory Horn Switch

IMPORTANT: You are not required to use the relay supplied with the kit because the vehicle

factory system already has a relay.

A. For two (2) wire systems: If a vehicle’s factory horn has two (2) terminals, simply transfer

the wires to the compressor’s terminals.

IMPORTANT: when testing the horns, if compressor motor turns on but the horn does not

sound, reverse the wires connected at the bottom of the compressor.

B. For one (1) wire systems: If a vehicle’s factory horn has one (1) terminal simply transfer

wire to the compressor’s positive (+) terminal.

C. Using a 16-gauge wire, the compressors’ negative terminal is connected to any metal body

bolt. A ground connection should be free of rust and paint.

8. Electrical Connections for a New Horn Button Switch:

Install the relay in a dry location with the terminals facing downward near the compressor.

Refer to Figure 5 for wiring

D. Connect relay terminal 87 to the positive terminal at the bottom of the compressor. Use16-

gauge wire or heavier.

E. Connect relay terminal 85 to the horn switch terminal. The other horn switch terminal is

connected to ground, (body of vehicle). An 18-gauge wire is suggested for this connection.

F. Connect relay terminals 30/86 to positive (+) 12-volt battery, alternator or accessories. Use

16-gauge or heavier wire. A 20-ampere fuse should be insalled as shown in Figure 5.

G. Recap of Terminal Connections for New Horn Switch:

Terminals: 30/86: the two terminals are connected to 12 volt positive (+) using a fuse.

Terminal: 85 is connected to the horn switch. The other terminal of the horn switch is

connected to ground.

Terminal: 87 is connected to the positive (+) terminal of the compressor.

20 AMP Fuse

(NOT INCLUDED)

Ground

Ground

Compressor

Relay

Battery

Horn Switch

Fig 5

Installation

instructions for

Figure D

Electrical Connections for a New Horn Button Switch

WEATHER PROTECTION COVERS

9. It is recommended that you always use the protection covers. They will prevent damage to the

trumpet’s diaphragm from rain, bugs, dirt, etc. Assemble Horn Protection Covers as shown in

Fig. 6 below. Do not tighten screws, brackets are placed into position on the front of each trum-

pet and then tighten screws.

If you need help installing your new Wolo horn, our technicians are available to

answer your questions, Monday thru Friday, from 9 AM to 4 PM EST at 1-888-550-4676.

Fig. 6

Fig. 4