Mechanical angle applicator method – USG Sheetrock Paper-Faced Metal Bead and Trim User Manual

Page 7

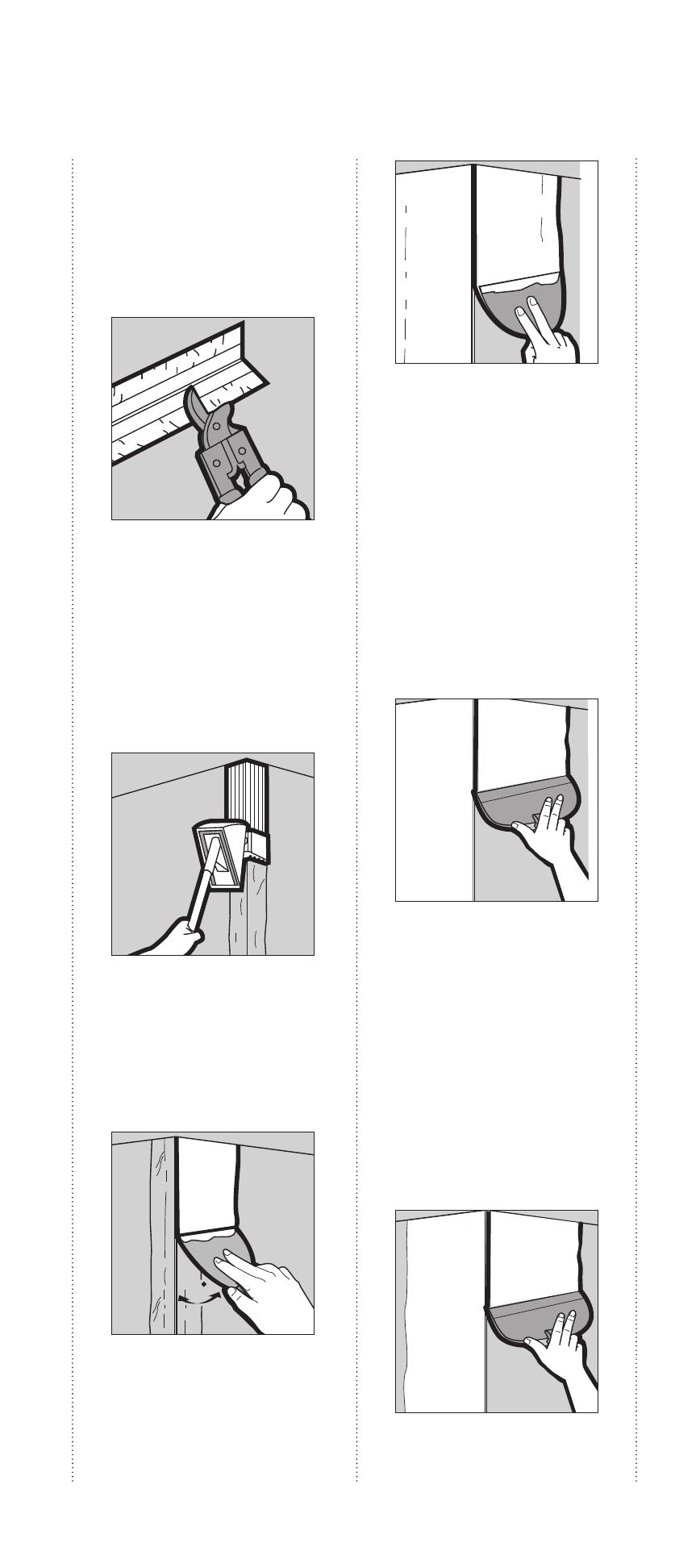

1 Measure length of corner;

cut trim to length with metal

snips. On vertical wall instal-

lations, cut the corner trim

1/2 (12.7 mm) shorter

than the wall height.

1

2

2

2 Apply ready-mixed s

hEEtrock

joint compound (taping,

all-purpose, or lightweight

all-purpose) or s

hEEtrock

D

urabonD

or E

asy

s

anD

setting-type joint compound

to drywall using mechanical

angle applicator.

1

2

2

3 Place trim on wall and press

into position. Corner bead

should be pressed tight to

ceiling. Embed trim by run-

ning the knife over it with

even pressure at a 45° angle.

PG 6 Paper Faced Metal Bead and Trim Installation Guide Illustrations

6

Mechanical Angle Applicator Method

45

3

5

2

1

4

4 Wipe off excess compound

with a damp sponge (or a 4

taping knife), eliminating any

air bubbles under the paper.

Allow to dry.

PG 6 Paper Faced Metal Bead and Trim Installation Guide Illustrations

6

Mechanical Angle Applicator Method

45

3

5

2

1

4

5 Using a 6 taping knife for outside

corners (4 for inside corners),

apply a second coat of joint

compound as smoothly as pos-

sible. (Do not use D

urabonD

or

taping joint compound for this

step.) Feather out 5 to 6 (125

to 150 mm) on each side from

nose of trim for outside corners

(1 (25 mm) for inside corners).

Let dry. Sand sides lightly where

needed.

PG 6 Paper Faced Metal Bead and Trim Installation Guide Illustrations

6

Mechanical Angle Applicator Method

45

3

5

2

1

4

6 Use an 8 or larger finishing

knife for outside corners (4-6

knife for inside corners) to apply

a finishing coat of compound.

(Do not use D

urabonD

or taping

joint compound for this step.)

Feather compound 8 (200 mm)

from nose of trim for outside cor-

ners (1 (25 mm) past previous

coat for inside corners). Let dry;

sand and prime.

PG 6 Paper Faced Metal Bead and Trim Installation Guide Illustrations

6

Mechanical Angle Applicator Method

45

3

5

2

1

4

6

Mechanical Angle

Applicator Method