Titus Pneumatic Controls IOM User Manual

Page 6

PNEU-IOM-6.0

5-2-05

Calibration Procedure for TITUS IIA Controller

A.

Direct Acting Cooling or Reverse

Acting Heating.

1.

Adjusting minimum air flow:

a.

Apply zero PSI signal to Port T

on the controller.

b.

If the minimum CFM equals

zero, the damper should

assume a closed position

(observe the indicator on the

end of the damper shaft). If not,

adjust the LO STAT knob on

the controller until the damper

is closed.

c.

If a non-zero minimum CFM is

required, read the differential

pressure for the desired CFM

from the calibration curve

corresponding to the inlet size

of the terminal being calibrate

(Page 8).

d.

Adjust the LO STAT knob until

the desired differential pressure

is read on the manometer

gauge. Allow several seconds

for the controls to react to the

system pressure and stabilize.

2.

Adjusting maximum air flow:

a.

Apply 15-25 PSI signal to

Port T on the controller.

b.

Refer again to the calibration

curve (Page 8).

c.

Adjust the HI STAT knob on

the controller until the

manometer gauge reads the

required differential pressure

from the curve.

NOTE: If actuator fails to respond,

see Guide to Service Procedures.

B.

Reverse Acting Cooling or Direct

Acting Heating

1.

Adjusting maximum air flow:

a.

Apply zero PSI signal to Port T

on the controller.

b.

Refer to the calibration chart

(Page 8). Read the differential

pressure for the desired

maximum CFM from the curve

corresponding to the inlet size

of the terminal being calibrated.

c.

Adjust the LO STAT knob on

the controller until the desired

differential pressure is read on

the manometer gauge. Allow

several seconds for the

controls to react to the system

and stabilize.

2.

Adjusting minimum air flow:

a.

Apply 15-25 PSI signal to

Port T on the controller.

b.

If the minimum CFM equals

zero, the damper should

assume a closed position

(observe indicator on the end

of the damper shaft). If not,

adjust the HI STAT knob until

the damper closes.

c. If a non-zero minimum CFM is

required, read the differential

pressure for the required CFM

from the curve (Page 8).

d.

Adjust the HI STAT knob on the

controller until the manometer

gauge reads the desired

differential pressure from the

curve.

NOTE: If actuator fails to respond,

see Guide to Service Procedures.

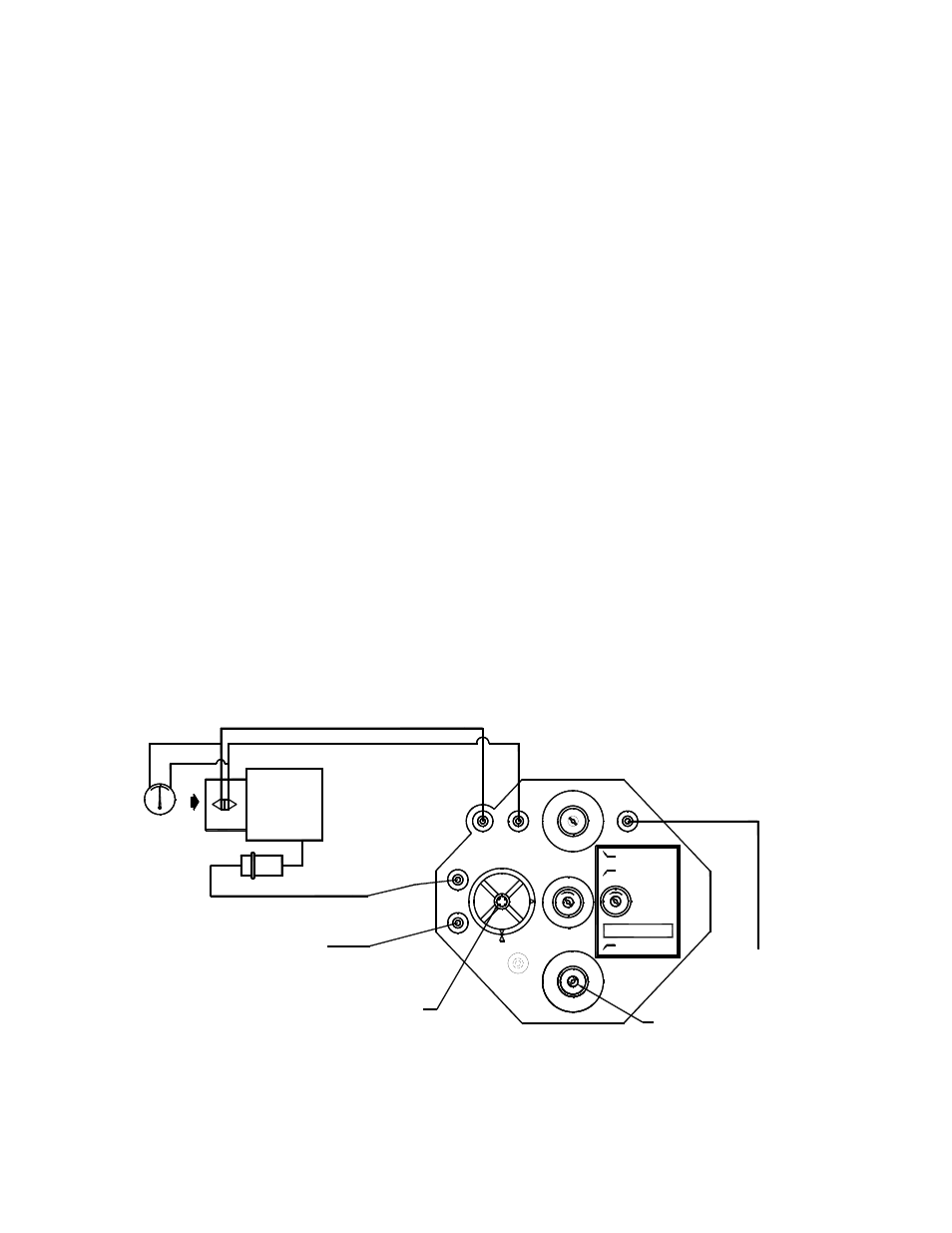

(FIELD ADJUSTERS HAVE KNOBS)

WITH 5/64" HEX ALLEN WRENCH

ALL ADJUSTMENTS CCW TO INCREASE

MAIN AIR (20-25 PSI)

(SUPPLIED IN NO POSITION)

CHANGE DAMPER ACTION

LOOSEN SCREW TO

MAGNAHELIC

SENSOR

(0-20" WG)

GAUGE

ACTUATOR

H

L

HI

LO

NO

DAMPER

BLUE

YELL

OW

M

B

H

GREEN

RED

R

G

N

I

C

NC

L

R

I

RESET SPAN

NC

HI STAT P

RESET START

LO STAT P

T

ROOM THERMOSTAT

(0-15 PSI)

WHITE

Figure 8. Titus IIA Controller