Titus Pneumatic Controls IOM User Manual

Page 2

PNEU-IOM-2.0

5-2-05

Quick-Check Procedure for TITUS I, II, and IIA Controllers

Preparing for Calibration

1.

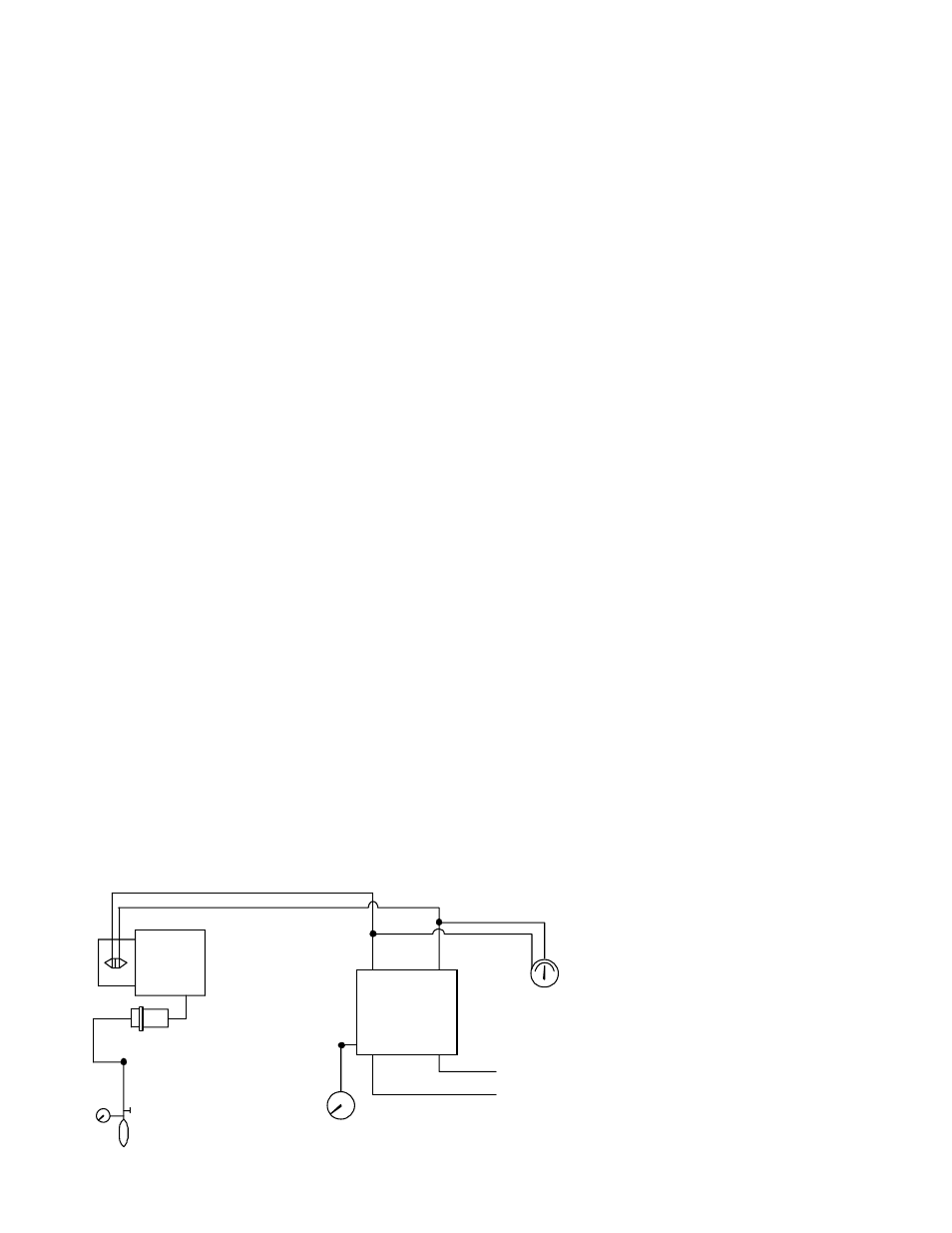

Disconnect the actuator tube

(yellow stripe) from controller

Port B.

2.

Connect squeeze bulb with 0 to 25

PSI gauge to the actuator.

3.

Connect 0 to 25 PSI gauge to

controller Port B (Figure 4).

A.

Direct Acting Cooling or Reverse

Acting Heating

1.

Apply zero PSI to thermostat

Port T.

2.

Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

3.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4.

Adjust the LO knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

5.

Read the differential pressure for

the desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7.

Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8.

Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond,

see Guide to Service Procedures.

B.

Reverse Acting Cooling or Direct

Acting Heating

For TITUS I Controllers

1.

Apply zero PSI to thermostat

Port T.

2.

Read the differential pressure for

the desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

3.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4.

Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

5.

Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7.

Adjust the LO knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8.

Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond,

see Guide to Service Procedures.

For TITUS II Controllers

1.

Apply 15 to 25 PSI to thermostat

Port T.

2.

Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

3.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4.

Adjust the LO knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

5.

Read the differential pressure of the

desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7.

Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8.

Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond,

see Guide to Service Procedures.

For TITUS IIA Controllers

1. Apply zero PSI to thermostat Port T.

2.

Read the differential pressure for

the desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

3.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4.

Adjust the LO knob on the face of

the controller until the gauge on

Port B 7.5 PSI ± 1.0 PSI.

5.

Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6.

Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7.

Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8.

Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond

see Guide to Service Procedures.

Figure 4. Controller Setup

GAUGE

0-25 PSI

GAUGE

0-25 PSI

SQUEEZE

BULB

SENSOR

ESV

0-2" W.G.

MANOMETER

5-10 PSI

ACTUATOR

YELLOW

LO

HI

GREEN

RED

HI

LO

YELLOW

B

T

M

WHITE

BLUE

MAIN AIR

(15-25 PSI)

ROOM THERMOSTAT

(0-15 PSI)

PNEUMATIC

CONTROLLER