Rab installation manual, Duct insulation and vapor proofing, Sound attenuation – Titus RAB IOM User Manual

Page 4: Condensate drain, Water piping, Motors and drives, Electrical connections

RAB Installation Manual

IOM-RAB-00

08-15-04

4 of 10

Duct Insulation and Vapor Proofing

Previously installed heating supply ductwork may already

have adequate insulation against excessive heat loss.

This insulation may be satisfactory for protection against

heat gain from summer cooling. Depending upon

application, additional insulation may be required.

Externally insulated ductwork must have adequate vapor

seal for summer operation, especially where duct is

exposed to high humidity conditions.

Warning

Before installing unit, determine whether the unit

weight can be supported safely.

Possible injury and damage may result due to

joist/truss overloading.

When return air duct connection is smaller than return air

inlet opening, construct the transition piece so the vertical

and horizontal dimensions of transition do not increase

more than one inch for every seven inches of length.

Allow a minimum of three feet of straight ductwork

preceding equipment inlet

Sound Attenuation

Flexible duct connections should be used between the unit

and both the supply and return ducts. Requires unit

vibration isolation for suspended and base-mounted units.

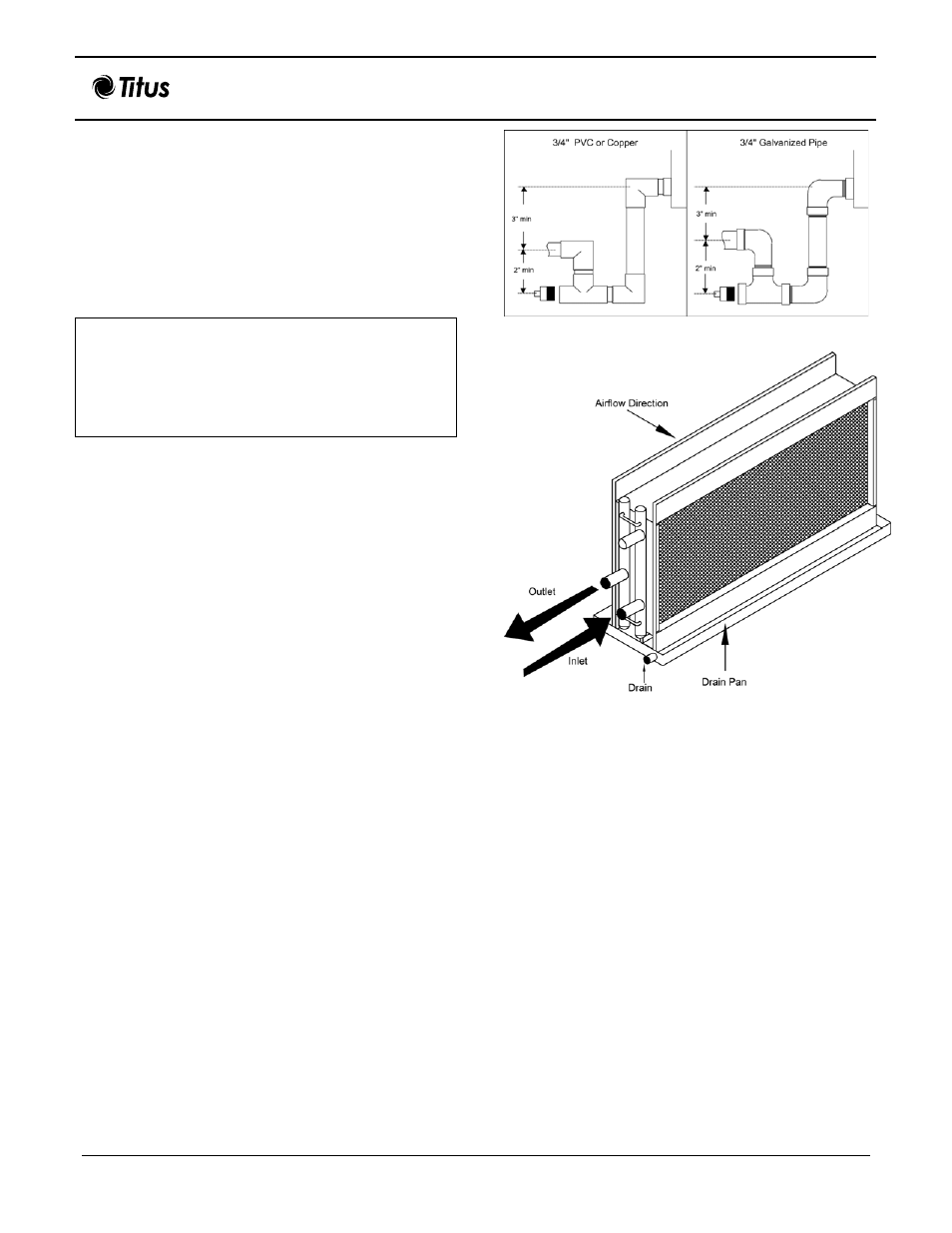

Condensate Drain

Install unit with 1/8-inch pitch toward condensate drain

opening. Condensate drain must consist of a minimum of

¾-inch copper tubing, ¾-inch galvanized pipe, or ¾-inch

PVC pipe. Figure 3 shows condensate drain setup. The

drain trap must be properly configured to ensure the

removal of all condensate runoff. Ensure drain pitches

downward at a slope of one inch every 10 feet.

Note 1: Incorrect trapping can hold water in pan,

causing overflow.

Note 2: Consult local codes for additional precautions

before installing condensate pan.

Water Piping

All piping must be supported, independent of coils. Swing

joints or flexible fittings must be provided to absorb

expansion and contraction strains. Rigid piping reduces

the effectiveness of vibration isolators. The water supply

should always be connected so the entering water is on

the leaving airside of the coil. Coils must be adequately

vented in order to prevent air binding. See Figure 4.

Note: Freeze-ups due to low air temperatures are not

covered under the warranty agreement.

Figure 3. Condensate Drain

Figure 4. Water Piping

Motors and Drives

Units are normally shipped with motor and drive installed.

However; when mounting a motor on the adjustable base

in the field, use extreme care to ensure proper alignment

and belt tension.

Electrical Connections

Each unit has a mounted control box and, typically, the

motor is to be wired to this box. Only ODP, single- and

three-phase motors on 800 to 2000 CFM units are factory-

wired to junction box. All other motors require field wiring

to junction box located on side of the unit cabinet.

Note: Unit must be permanently grounded in

accordance with NEC and local codes and

ordinances. See the typical wiring diagrams shown in

Figure 5.