Cold hot, Hot cold – Titus Pneumatic Controls for Dual Duct Terminals IOM User Manual

Page 4

M

T

ACTUATOR

ACTUATOR

CONTROLLER

T

M

Hi

B

LO

Cold

Hot

CONTROLLER

M

Lo

T

Hi

B

PNEU-DD-IOM-4.0 8-9-02

Adjusting Minimum and Maximum Air Flow for Units with Cold Inlet Sensor and Hot Discharge

Sensor

A. Direct Acting Thermostat Air

Flow Adjustment

1.

Cold inlet controller. Be sure the

cold inlet damper assumes a fully

closed position during heating

conditions. Apply 0 PSI pressure to

the thermostat connection of the

cold inlet controller. If the cold inlet

damper does not fully close, adjust

LO air flow know until the damper

closes. Allow several seconds for

the controls to react to system

pressure and stabilize.

To adjust cold deck maximum CFM:

a.

A p p l y 1 5 - 2 5 P S I t o t h e

thermostat connection on the

cold deck controller. Place a

manometer gauge across the

balancing tees at the cold deck

inlet.

b.

I f t h e m a n o m e t e r g a u g e

reading matches the required

differential pressure from the

calibration curve (Page 6 and

7 ) , n o a d j u s t m e n t i s

necessary.

c.

If adjustment is necessary, use

the adjusting tool stored in the

face of the controller (Titus II

only) or a standard flat-blade

screwdriver.

d.

Rotate the maximum HI knob

slowly. A delay in response

time has been deliberately built

i n t o t h e c o n t r o l s t o a v o i d

hunting. Allow several seconds

from controls to react and the

system to stabilize. Rotate the

know until the gauge shows the

required differential pressure.

N O T E : I f t h e a c t u a t o r f a i l s t o

r e s p o n d , s e e G u i d e t o S e r v i c e

Procedures.

To adjust Min./Mix CFM on hot controller

/ discharge sensor:

a.

Apply 8.0 PSI pressure to the

thermostat connection of the

cold deck controller.

b.

If Min./Mix CFM equals zero.

The hot inlet damper should

assume a closed position. If

not, adjust minimum LO knob

on the hot inlet controller until

the damper closes.

c.

If Min./Mix CFM is a non-zero

value, place a mano m e t e r

gauge across the balancing

tees of the hot deck inlet. If the

pressure matches the required

differential from the calibration

c u r v e ( P a g e 6 a n d 7 ) , n o

adjustment is necessary.

d.

If adjustment is necessary,

rotate the minimum LO knob

until the gauge s h o ws t h e

required differential pressure.

To adjust hot deck maximum CFM:

a.

Apply 0 PSI pressure to the

thermostat connection on the

hot deck controller. Place a

manometer gauge across the

balancing tees at the hot deck

inlet.

b.

I f t h e m a n o m e t e r g a u g e

reading matches the required

differential from the calibration

c u r v e ( P a g e 6 a n d 7 ) , n o

adjustment is necessary.

c.

If adjustment is necessary,

rotate the maximum HI knob

slowly. Rotate the knob until

the gauge reads the required

differential pressure from the

curve.

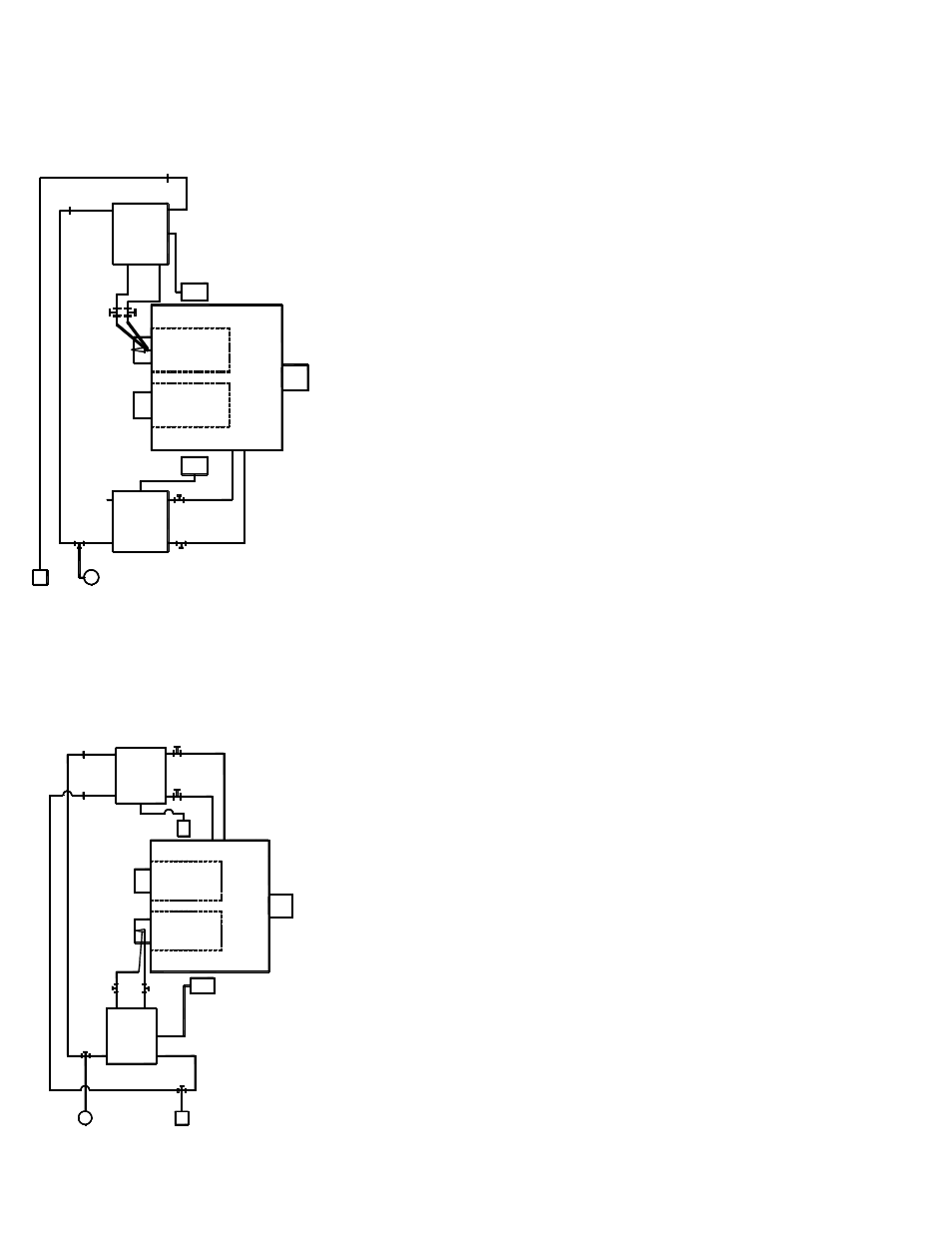

Figure 6. Constant Air Volume

Piping Diagram

Figure 7. Variable Air Volume

Piping Diagram

T

M

Lo

Hi

Hot

Cold

Hi

M

T

B

T

M

CONTROLLER

ACTUATOR

CONTROLLER

LO

B