Sound attenuation, Motors and drives, Electrical connections – Titus HAB Horizontal Air Handler Belt Drive User Manual

Page 5: Installation of options, Grille plenum, Preparation, Water piping, Hab installation manual

HAB Installation Manual

IOM-HAB-00

06-30-04

Water Piping

All piping must be supported, independent of coils. Swing

joints or flexible fittings must be provided to absorb

expansion and contraction strains. Rigid piping reduces

the effectiveness of vibration isolators. The water supply

should always be connected so the entering water is on

the leaving airside of the coil. See Figure 7. Coils must be

adequately vented in order to prevent air binding.

Note: Freeze-ups due to low air temperatures are not

covered under the warranty agreement.

Sound Attenuation

Flexible duct connections should be used between the unit

and both the supply and return ducts.

Both suspended and base-mounted units require unit

vibration isolation.

Motors and Drives

Units are normally shipped with motor and drive installed.

However; when mounting a motor on the adjustable base

in the field, use extreme care to ensure proper alignment

and belt tension.

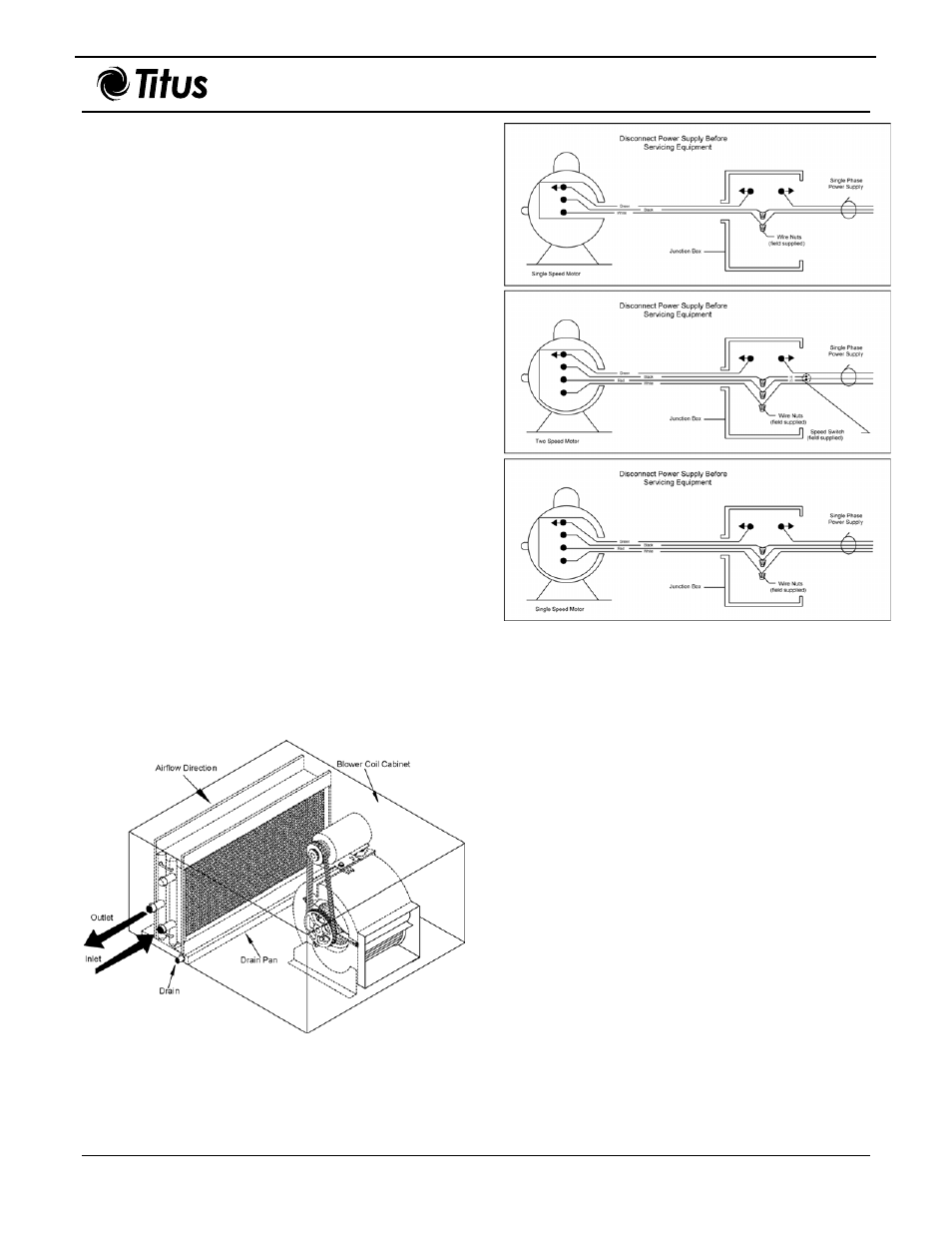

Electrical Connections

Each unit has a mounted control box and, typically, the

motor is to be wired to this box. Only ODP, single- and

three-phase motors on 800 to 2000 CFM units are factory-

wired to junction box. All other motors require field wiring

to junction box located on side of the unit cabinet.

Note: Unit must be permanently grounded in

accordance with NEC and local codes and

ordinances. See the typical wiring diagrams shown in

Figure 8.

Figure 7. Blower Coil Connections

Figure 8. Wiring Diagrams

Installation of Options

In addition to the standard equipment, the following

optional equipment may require consideration during

installation.

•

Grille plenum.

•

Mixing box.

•

Electric heat.

•

Face and bypass damper filter section.

Grille Plenum

Figure 11 shows the setup of an HAB model and grille

plenum. The grille plenum is available in two sizes. Grille

plenums sized for the HAB08 through 20 models have one

opening, while the plenum sizes for the HAB30 through 80

models have two openings.

Preparation

•

Remove shipping screws (red-headed screws).

•

Remove smaller screws from the cabinet front that

align with the pre-punched ¼-inch holes of the grille

plenum. The screws aligning with the large ½-inch

holes are to remain in place.

5 of 9