Standard installation, Ductwork, Hab installation manual – Titus HAB Horizontal Air Handler Belt Drive User Manual

Page 3

HAB Installation Manual

IOM-HAB-00

06-30-04

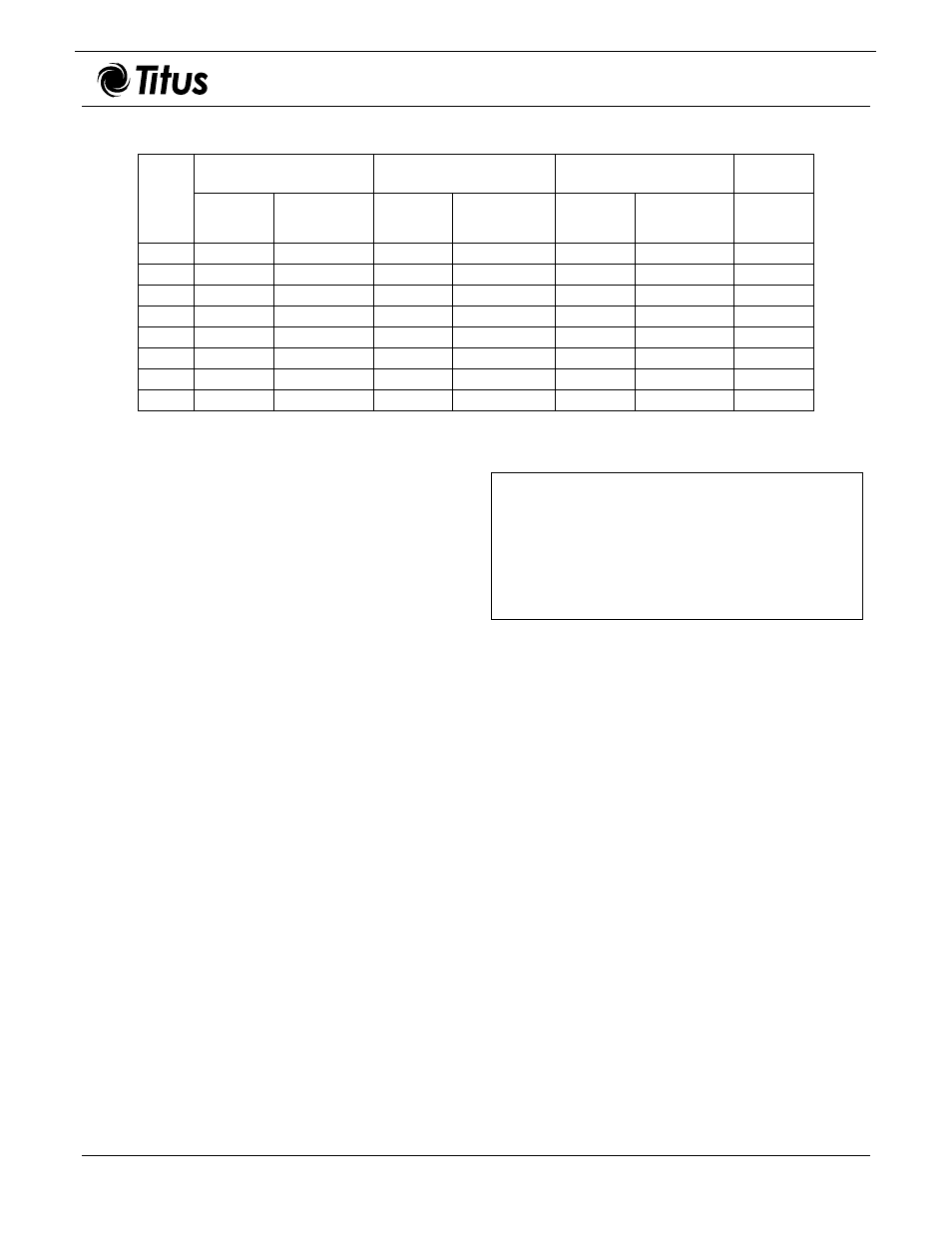

Table 2. HAB Installation Data

4-Row Unit

6-Row Unit

2-Row Coil

1-Row Coil

(Note)

Model Connection

Size OD

SWT

Ship Weight

(lbs)

Connection

Size OD

SWT

Ship Weight

(lbs)

Connection

Size OD

SWT

Ship Weight

(lbs)

Connection

Size OD

SWT

HAB08

3/4"

145

3/4"

156

5/8"

13

5/8"

HAB12

3/4"

171

7/8"

190

7/8"

18

5/8"

HAB16

7/8"

200

1-1/8"

222

7/8"

25

7/8"

HAB20

1-1/8"

244

1-1/8"

263

1-1/8"

30

7/8"

HAB30

1-1/8"

457

1-3/8"

475

1-1/8"

41

N/A

HAB40

1-3/8"

512

1-5/8"

547

1-1/8"

53

N/A

HAB60

1-3/8"

700

1-5/8"

787

1-3/8"

86

N/A

HAB80 (2) 1-5/8"

775

(2) 1-5/8"

855

(2) 1-1/8"

106

N/A

Note: Shipping weight of a one-row coil is same as two-row coils.

Standard Installation

Basic installation procedure covers verifying and/or

installing the following items.

•

Ductwork.

•

Duct insulation and vapor proofing.

•

Unit placement.

•

Sound attenuation.

•

Condensate drain.

•

Water piping.

•

Motors and drives.

•

Electrical connections.

Note: If mixing boxes form part of the unit, install the

mixing boxes prior to installing unit. See Mixing Box

Installation topic within this document.

Ductwork

Use accepted industry practices and design guidelines of

the ASHRAE Fundamentals Handbook. Ductwork must

comply with all building codes and the National Fire

Protection Association’s pamphlet 90A and 90B.

Carefully inspect any previously installed ductwork to

determine suitability.

Note: Ductwork should be of a size meeting

requirements of the installation. Ductwork should

transition gradually from a smaller size blower

outlet to required duct run size to avoid excessive

loss of air velocity.

DANGER

BEFORE INSTALLING UNIT, DETERMINE WHETHER

THE UNIT WEIGHT CAN BE SUPPORTED SAFELY.

POSSIBLE INJURY AND DAMAGE MAY RESULT DUE

TO JOIST/TRUSS OVERLOADING.

When return air duct connection is smaller than return

inlet opening, construct the transition piece so the vertical

and horizontal dimensions of transition do not increase

more than one inch for every seven inches of length.

Allow a minimum of three feet of straight ductwork

following an equipment outlet.

Suspend unit or support unit from floor. Models HAB08

through 20 have 3/8-inch weld nuts provided in each

corner of the top for suspending the unit with threaded

rod. See Figure 3. Models HAB30 through 80 have 7/8-

inch knockouts in each corner of top and bottom panels

for suspension rods to pass through, located 3-1/2 inches

in from corners on centerline. It is recommended that

angle iron or unistrut be used under the unit for support

(these support pieces should extend approximately one

inch beyond each end of the unit, see Figure 4.

Ensure the suspension rods are located so the rods do

not block access panels or interfere with electrical,

mechanical or drain functions of the unit.

Install unit with 1/8-inch pitch toward condensate drain

opening.

3 of 9