Bazooka – TapeTech T05CF Bazooka Continuous Flow Taper User Manual

Page 9

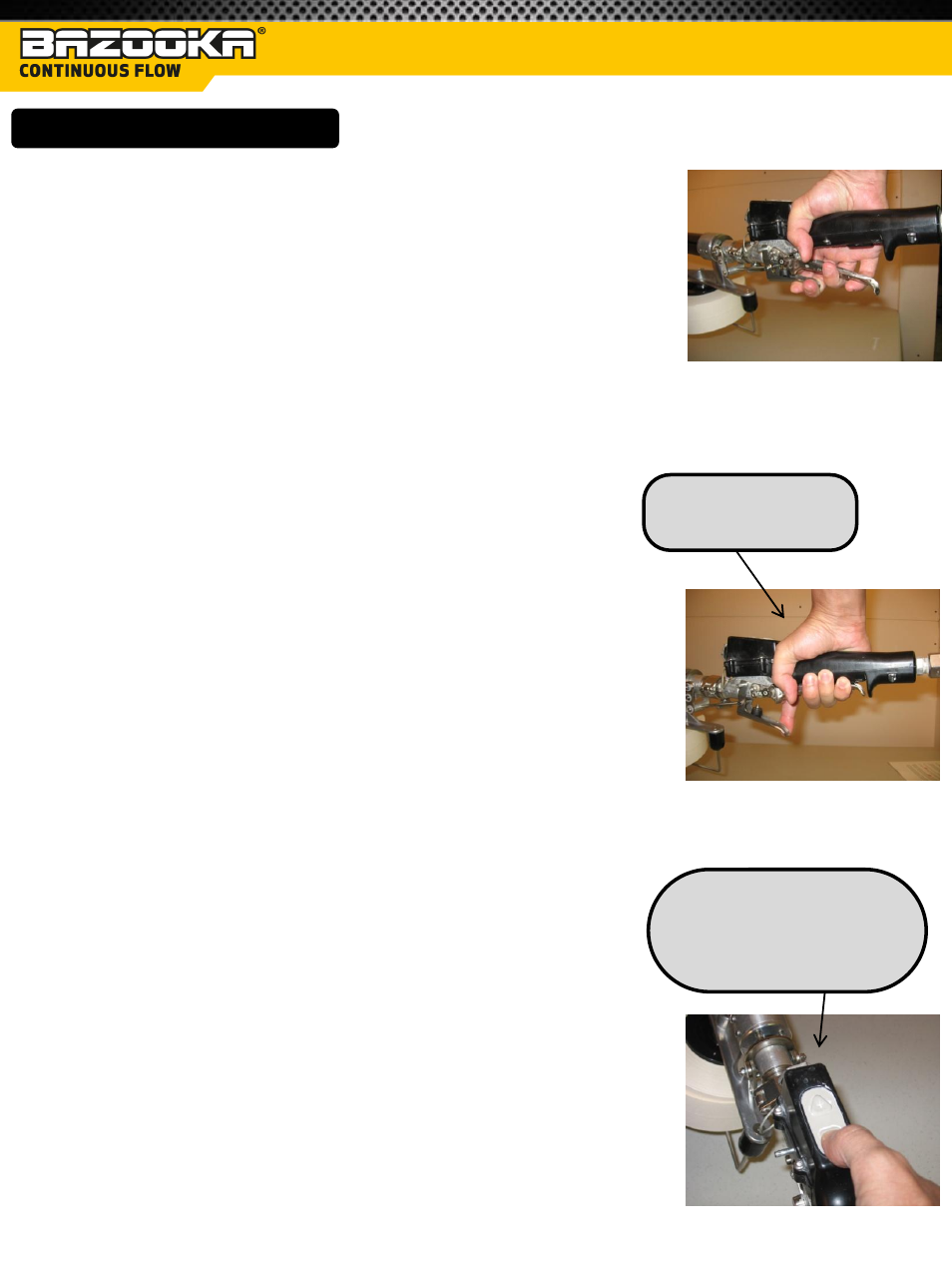

12. The taper is operated by placing one hand on the inline mechanical

valve, controlling the compound flow, and the other hand on the

taper control tube, controlling tape advancing and cutting.

13. Normally, the control tube is held at the top most end of its stroke

during taper operation.

© 2011 AMES TAPING TOOLS

8

BAZOOKA®

(cont’d)

14. The spring loaded creaser wheel may also be retracted temporarily

by operating the creaser trigger with the hand on the inline

mechanical valve.

15. If the lever is used, it is released once the taper is positioned so that

the valve lever can be operated.

16. During normal operation, the creaser is extended and always

applying some amount of pressure to seat the tape onto the wall.

17. The flow of material from the pump to the taper is actuated by fully

squeezing the valve lever.

18. Joint compound will flow through the hose, into the taper and onto

the exposed tab of tape.

19. You are now ready to tape your first joint. An additional tape

advance may be helpful for starting some joints, especially ceiling

and ceiling angles.

20. The operator must ensure the proper amount of compound is

dispensed onto the tape by matching the speed of the taper head

with the flow of material from the pump.

21. For best results, the operator will need to ensure that the head of

the tool travels at a consistent speed over the full length of the

joint or excess and/or insufficient amounts of compound will result.

22. Speed can be adjusted by pressing the adjustment buttons on the

inline mechanical valve.

23. Speed cannot be increased above that set by the control knob on the

pump, but can be adjusted up and down below that setting.

Flow rate adjustments can

be made using the “+” and

“-” buttons on the inline

valve controller

Start compound flow

by fully squeezing the

valve lever

- T8034 Bazooka CFS 34 Finishing Box Handle T8042 Bazooka CFS 42 Finishing Box Handle T8054 Bazooka CFS 54 Finishing Box Handle T8072 Bazooka CFS 72 Finishing Box Handle T14CF Bazooka CFS 42 Corner Finisher Handle CFFULL Cont. Flow Full Bundle CFFLAT Cont. Flow Flat Finishing Bundle CFCRNR Cont. Flow Corner Finishing Bundle T14EC Bazooka CFS 60 Corner Finisher Handle T20CF Bazooka CFS 7 Finishing Box (slimline) Bazooka T30CF Bazooka CFS 12 Finishing Box (slimline)