Bryant 548F User Manual

Page 14

14

CONTROLS (cont)

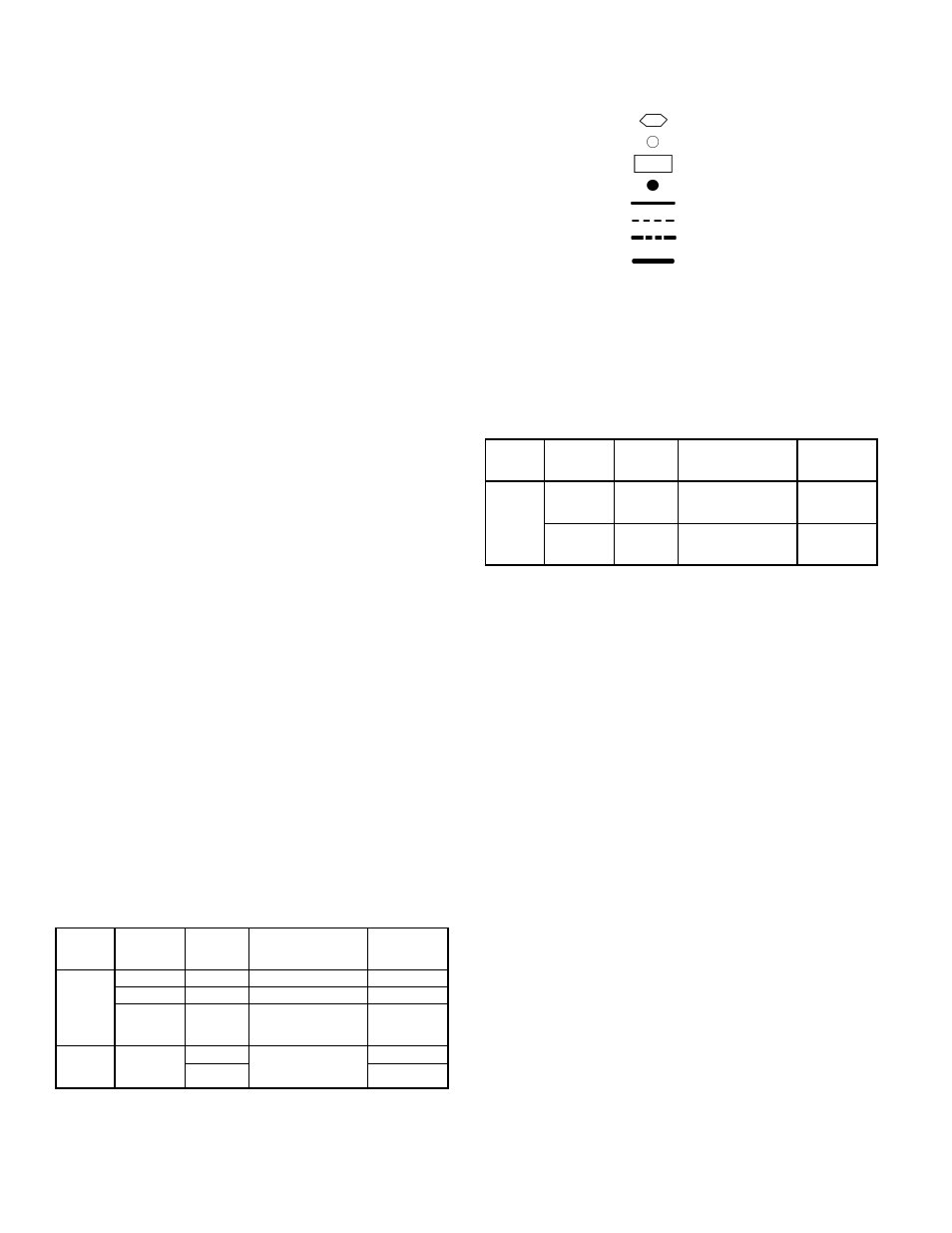

LEGEND

APPLICATION DATA

1. OUTDOOR INSTALLATION — Units approved for outdoor

installation only.

2. DUCTWORK — Secure vertical discharge ductwork to roof

curb. For horizontal discharge applications, either attach

ductwork to unit, or use field-supplied flanges attached to

the horizontal discharge openings and attach all ductwork

to flanges.

3. HORIZONTAL ECONOMI$ER — A field-installed acces-

sory for horizontal discharge applications. Field-installed

power exhaust accessory also available for vertical or hori-

zontal EconoMi$er applications (036-120).

4. THRU-THE-BOTTOM POWER CONNECTIONS — For

applications requiring thru-the-bottom connections, Bryant

accessory thru-the-bottom package must be purchased to

ensure proper connections (036-120).

5. THERMOSTAT — Use of 2-stage heating and cooling ther-

mostat is recommended for all units. A 2-stage cooling ther-

mostat is required on units with accessory economizer to

provide integrated cooling. A two-stage thermostat is

required for all 548F/549B090,120 and 542J150,180 units.

6. HEATING-TO-COOLING — All units are automatic

changeover from heating to cooling when automatic

changeover thermostat and subbase are used.

7. AIRFLOW — Units are draw-thru on cooling and blow-thru

on heating.

8. MAXIMUM AIRFLOW — To minimize the possibility of con-

densate blow-off from indoor coil, airflow through units

should not exceed 500 cfm/ton.

9. MINIMUM AIRFLOW — For cooling, minimum airflow is

300 cfm/ton. For 548F units with electric heating, the

required minimum cfm is 900 for 548F036; 1200 for

548F048; 1500 for 548F060; 1800 for 548F072; 2250 for

548F090; 2500 for 548F102; and 3000 for 548F120, with

the following exceptions:

For 549B and 542J units with electric heating, the required

minimum cfm is 900 for 549B036; 1200 for 549B048; 1500 for

549B060; 1700 for 549B072; 2250 for 549B090; 3000 for

549B120; 3900 for 542J150; and 4500 for 542J180, with the fol-

lowing exceptions:

10. MINIMUM AMBIENT COOLING OPERATING TEMPERA-

TURE — The minimum temperature for standard units is

25 F (036-120) and 40 F (542J150,180). With accessory

Motormaster® control, units can operate at outdoor temper-

atures down to –20 F.

11. INTERNAL UNIT DESIGN — Due to Bryant’s internal unit

design (draw-thru over the motor), air path, and specially

designed motors, the full horsepower (maximum continuous

bhp) listed in the Physical Data table and the notes following

each Fan Performance table can be utilized with confidence.

Using Bryant motors with the values listed in the Physical

and Fan Performance Data tables will not result in nuisance

tripping or premature motor failure. The unit warranty will

not be affected.

AHA

— Adjustable Heat Anticipator

CB

— Circuit Breaker

CC

— Cooling Compensator

CLO

— Compressor Lockout

DAT

— Discharge Air Thermistor

DM

— Damper Motor

EAS

— Economizer Actuator

Auxiliary Switch

EMC

— Economizer Motor Contactor

FU

— Fuse

IFC

— Indoor-Fan Contactor

IFR

— Indoor-Fan Relay

L

— Light

LLS

— Liquid Line Solenoid

OAT

— Outdoor-Air Thermostat

PL

— Plug Assembly

SR

— Solenoid Relay

TB

— Terminal Block

TC

— Thermostat Cooling

TH

— Thermostat Heating

TRAN — Transformer

UR

— Unloader Relay

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Factory Wiring

Field Wiring

Option/Accessory Wiring

To Indicate Common Potential

Only, Not To Represent Wiring

UNIT

548F

UNIT

VOLTAGE

HEATER

kW

UNIT

CONFIGURATION

REQUIRED

MINIMUM

CFM

120

208/230

42.4

Horizontal

3200

208/230

50.0

Horizontal

3200

460

50.0

Horizontal

or

Vertical

3200

090-120

575

17.0

Horizontal

or

Vertical

2800

34.0

2350

UNIT

549B

UNIT

VOLTAGE

HEATER

kW

UNIT

CONFIGURATION

REQUIRED

MINIMUM

CFM

120

208/230

50.0

Horizontal

or

Vertical

3250

460

50.0

Horizontal

or

Vertical

3400