Heavy duty plastic lockers – 40000 series, Locker base installation instructions – Salsbury Industries 40000 Series Heavy Duty Plastic Lockers User Manual

Page 2

Heavy Duty Plastic Lockers – 40000 Series

Locker Base Installation Instructions

IMPORTANT: Make sure the base is square and level before anchoring to the floor. The base may be square but

not level, so be sure to check both. Shim under the base if necessary. This will ensure proper locker operation.

NOTE: The base front pieces are precut to length for 1-wide (12”) or 3-wide (36”) lockers, and come with slotted base side pieces. The length of the

base front pieces may be trimmed during installation by cutting to the desired length. DO NOT cut the base side pieces. The side pieces are the

correct length for 18” deep lockers.

Each set of base pieces includes a package of angle brackets to attach the base pieces to the floor, ¼” x 1-3/4” Tapcon screws to fasten the angle

bracket to the floor, and #10 x ½” sheet metal screws to attach the brackets to the base front and side pieces.

1. Plan the locker layout. Measure and mark placement lines on the floor for the locker bases. One or two lockers will require one or two 1-wide

bases. Three or more lockers in a row will require 3-wide bases and perhaps one or two 1-wide bases. As supplied, the bases are 1” wider than the

basic 12” wide locker to accommodate two (2) 1/2” thick side panels. As additional lockers and bases are arranged in a row with a side panel at one

end or both ends, some of the base front piece(s) must be trimmed by 1” or 1/2” to maintain a flush surface alignment between the end panel and the

base side piece. If side panels are not being used, further trimming of the front base pieces may be necessary

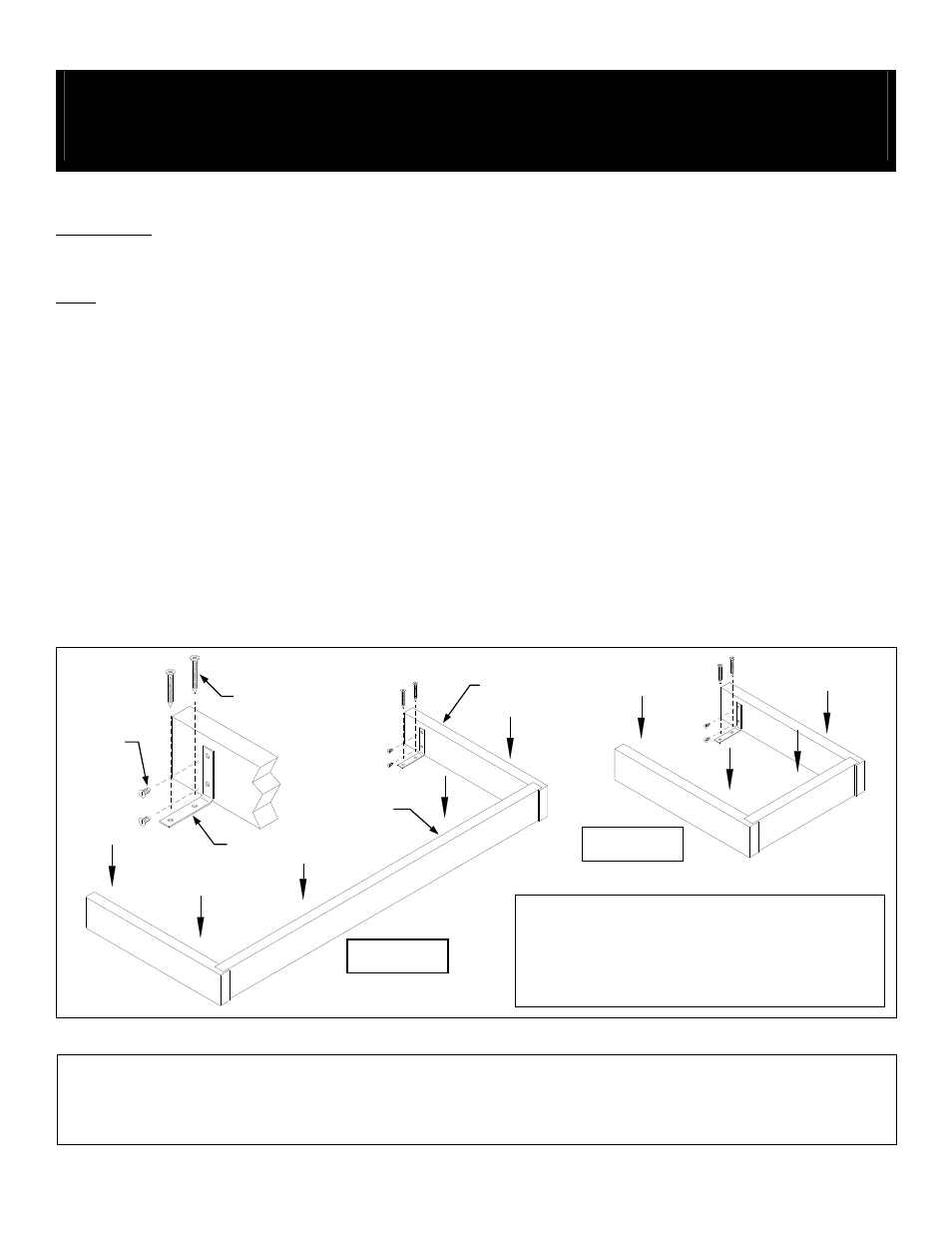

2. Position the base side and front pieces per the floor layout. The ends of the base front pieces fit into the slots in the base side pieces. See the

illustration below. Square and level the base front pieces and side pieces using shims as required. If shims are used, place them under the

mounting brackets perpendicular to the bracket.

3. Using the applicable mounting hardware supplied, anchor the base pieces to the floor. Use a 3/16” masonry drill bit for the 1/4” x 1-3/4” Tapcon

screws. Use at least two (2) angle brackets for each front piece or side piece.

Base Installation

Side Piece

Tapcon Screw

Sheet

Metal

Screws

Angle Bracket

Front Piece

1-Wide Base

Use 1/4” x 1-3/4” Tapcon concrete screws (blue) to attach

angle brackets to floor. Drill pilot hole with 3/16” masonry bit.

Use #10 x ½” sheetmetal screws to attach angle brackets to

plastic base members.

3-Wide Base

SALSBURY INDUSTRIES

1010 East 62

nd

Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

@

lockers.com

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2010 Salsbury Industries. All rights reserved. (Rev. 05, 1/13/2010) Page 2 of 6