Salsbury Industries 10000 Series Solid Oak Executive Lockers User Manual

Installation instructions, Salsbury industries, Hardware supplied with each locker

SALSBURY INDUSTRIES

1010 East 62

nd

Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

@

lockers.com

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2008 Salsbury Industries. All rights reserved. (Rev. 04, 5/8/2008)

Solid Oak Executive Lockers – 10000 Series

Installation Instructions

Thank you for selecting the 10000 Series Solid Oak Executive Lockers. We are confident that the quality and construction of the lockers will prove to

be a good investment. These instructions are intended to assist you in a typical wall-anchored or back-to-back locker installation. Individual job

conditions will dictate the type of fasteners and whether the lockers must be anchored to the wall, the floor, or both.

The 10000 Series Solid Oak Executive Lockers require minimal

assembly. The basic lockers are factory assembled. It may be

necessary to install the bases onto the floor, the lockers onto the bases

and to each other, the optional side panels to the exposed sides of the

lockers, and the lockers to a wall. See the next page for an illustration of

three lockers being installed.

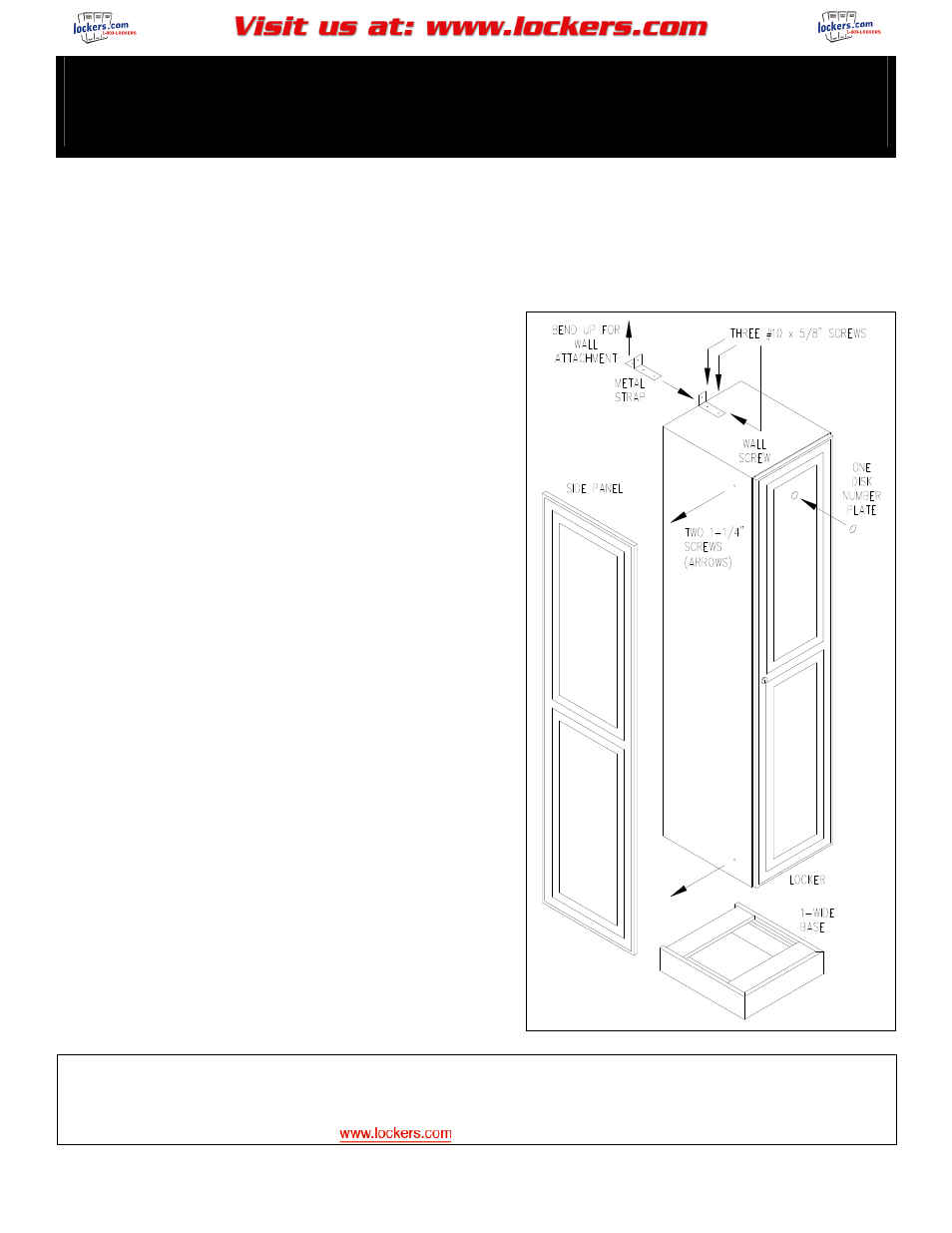

Hardware Supplied with Each Locker

1. One metal wall strap with three holes to attach locker to wall or back-

to-back. Bend the strap to tie locker to wall as shown in illustration.

2. Three #10 x 5/8” long hex-head sheet metal screws to attach strap to

top of lockers back-to-back or between locker and wall.

3. Two #10 x 1-3/8” long hex-head machine screws to fasten lockers

together side-by-side. Mating t-nuts are pre-installed in locker walls.

See next page for illustration of three lockers being installed.

4. Two 1-1/4” long drywall screws to attach side panel to locker. Side

panels may be purchased as an option.

5. One disk number plate.

Installation Instructions

1. Bases should be set in place and leveled. The rear edge of the base

should touch the wall or the other base if lockers are installed back-to-

back. There are 1-wide and 3-wide bases.

2. If the back of the locker is against a wall, bend the metal strap as

shown in the illustration. Set the locker on the base spaced 5/8” from the

wall for ventilation air. The metal straps will be installed in Step 5 below.

Leave the metal strap flat for fastening lockers back-to-back. Allow a 1-

1/4” ventilation space between the backs of lockers if lockers are back-to-

back and side panels are being installed. The metal straps will be

installed in Step 5 below.

Lockers alongside a wall with padlock type locking must be spaced 5/8”

from the side wall to allow swing room for the padlock.

3. Bolt multiple lockers together through the two unused holes and tee

nuts near the door hinges.

4. Attach the finished side panels (optional) flush with the front of the

locker body (not the door) allowing the excess to cover the 5/8” rear air

space.

5. Once the lockers are plumb and level, attach the bent or flat metal

straps to the top of the lockers and to the wall or other lockers as

required.

6. Peel backing from disk number plate, align, and press into

recess.

Illustration – One Locker